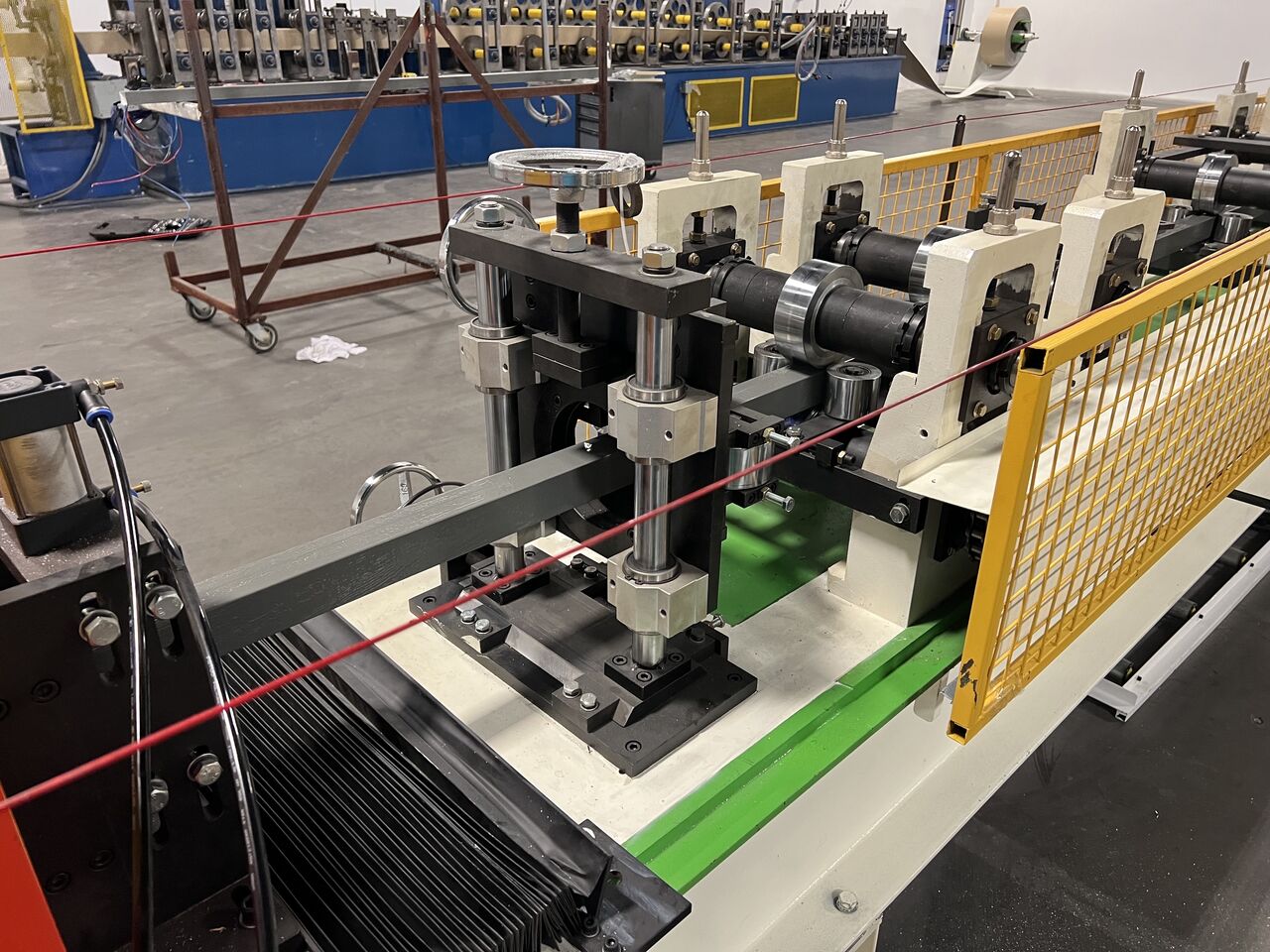

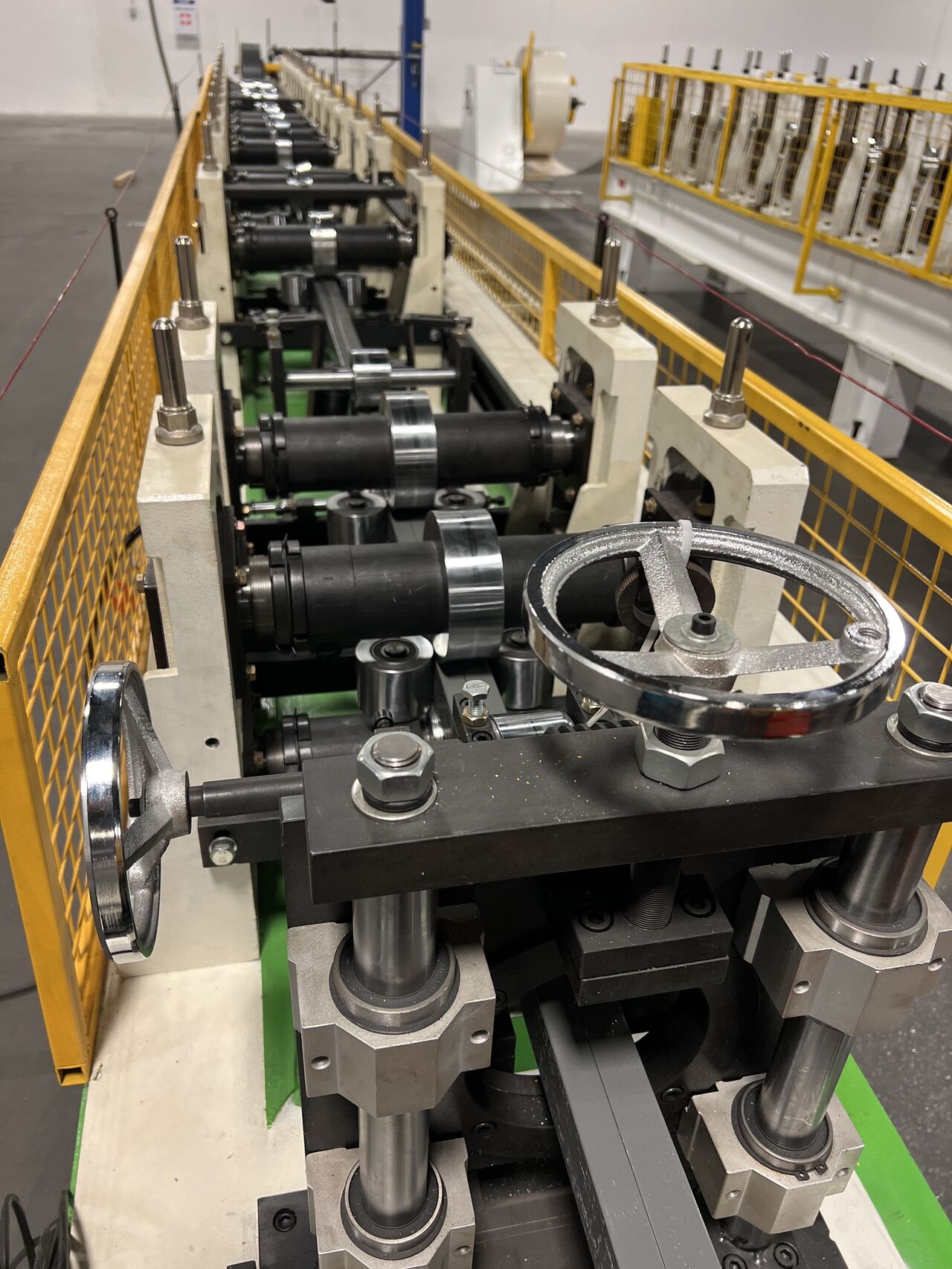

2x2 Tube Rollformer With Flying Saw

Get a Quote

Send us a message and we’ll get back to you shortly.

2 x 2 Tube Roll Forming Machine Specifications

- Designed and manufactured for Patio and Pergola industry.

- Profile - 2" x 2" Tube

- Coil Width - 9.5"

- Forming Speed - 70 - 80

- Material thickness - 0.27

- Machine Weight - 6 Ton

- Machine Footprint - 33ft x 4 ft

- Main power - 240v - 3ph - 60Hz

- Motor - 8 Hp

- Gearbox - Chain Drive

- Stations - 22

- Cutting type - Flying saw

- Control system - Delta

- Safety covers- optional

- E Stops

- FOB Orlando, Florida

2 x 2 Tube Roll Forming Machine Description

A 2 x 2 tube roll forming machine is a type of manufacturing equipment used in the metalworking industry to produce square or rectangular tubes from flat metal strips or coils. Here's an overview of what this machine does and how it works:

- Tube Formation: The primary purpose of a tube roll forming machine is to take a flat strip or coil of metal (typically steel or aluminum) and gradually shape it into a square or rectangular tube. The "2 x 2" specification likely refers to the size of the tube it can produce, meaning it can create tubes with a cross-sectional dimension of 2 inches by 2 inches.

- Roll Forming Process: Roll forming is a continuous bending process where the metal strip passes through a series of rolls or rollers, each with a specific contour. These rollers progressively bend and shape the metal until it reaches the desired tube profile. The rolls are carefully designed to ensure precise dimensions and consistent quality in the final product.

- Material Feeding: The metal strip or coil is usually fed into the machine's entry section, where it is guided through a series of rollers.

- Roller Set-Up: The machine has a set of rollers that are configured to bend and shape the metal into a square or rectangular tube. These rollers are adjustable to accommodate different tube sizes and shapes.

- Forming Process: As the metal strip passes through the rollers, it undergoes a series of bending operations. The initial rollers might bend the edges of the strip upward to form the sides of the tube, while subsequent rollers continue to shape and size the tube until it reaches the 2 x 2 dimensions.

- Cutting and Finishing: Some tube roll forming machines may include cutting tools or mechanisms to trim the tube to the desired length and ensure clean, square ends. Additional finishing processes like welding or seam closing may also be integrated into the machine.

- Output: The machine continuously produces square or rectangular tubes at a consistent rate. The finished tubes are typically collected or stacked for further processing or packaging.

These machines are commonly used in various industries, including construction, automotive, and manufacturing, where square or rectangular tubes are required for a wide range of applications such as structural supports, frames, and conduits. They offer advantages in terms of cost-effectiveness, precision, and efficiency compared to other methods of tube production. The specific design and capabilities of a 2 x 2 tube roll forming machine may vary depending on the manufacturer and the requirements of the intended application.

All roll forming machinery is fully assembled at our factory in Orlando Florida. and comes with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

To request a quote or If you have any questions about our machines, please fill out the contact form below.