Rollforming Lines

A roll-forming line consists of many parts. At Rollforming LLC we produce complete roll forming machines to help our customers achieve their varying goals.

Posted on Wednesday, August 31, 2022

A complete Roll Forming line usually requires the following parts:

- Coil Decoiler or Uncoiler machine

- Coil Loading Device

- Straightening Machine Servo Feeder Hydraulic or Eccentric Press (these are only required if punching is needed)

- Punching Die Set Rollforming Machine Flying Shears - these aren’t necessary for all machine types

- Stacking Unit

A roll forming line can be fed differing coil weights. These can vary massively from anywhere between 4 tonnes up to a maximum of 20 tonnes. Different coil thicknesses can also be fed into a roll-forming machine too. Common materials that are fed into the line include galvanized and galvannealed steel, stainless steel, aluminum, copper, brass, and bronze.

Roll forming is the process of bending and manipulating the strips or coils of metal that are fed into the machine with a very specific end product in mind. The metal is passed along the roll-forming lines and bent continuously until the end result is desired.

The components of a roll forming line include:

Front-end equipment

The front-end equipment is all the machinery that prepares the coils to be fed into the machine and begin manipulating and being the metal. The coils may need correction before being fed into the machine as they will likely have been tightly rolled for some time. Coils are loaded into the uncoiled by using a floor or pit-mounted coil car. The coil is opened and flattened, and the lead end will be trimmed. The lead end may be joined to the trailing end of the last coil fed into the machine if a continuous roll-forming process is required.

Strip Accumulators and Slack Loops

Strip accumulators and slack loop help roll formers fabricate metal more efficiently. These parts permit the coil strip to pause so that a pre-punch press stroke can occur while ensuring that the roll form mill runs continuously. These are used so that stopping and starting don’t occur, which could make the process less efficient and cost the business time and money.

Pre-Punch Presses

When passing through an in-line punch press, the metal can be punched with holes or notches as per the design, which eliminates the need for secondary fabrication steps and reduces production times too.

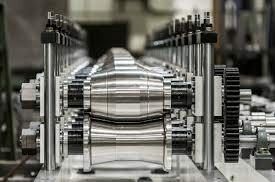

The Roll Die Mill

The mill is the section of the roll forming line where the metal is continuously bent and shaped as it is passed through a series of rollers. A roll-forming machine typically houses around anywhere between 10 and 24 pairs of roller die stands. Once the metal passes through the rollers, it then runs through a series of straightening dies and side rollers. The purpose here is to adjust any twists, bows, or cambers in the metal to ensure complete accuracy when the part comes out of the end of the machine.

Cutoff & Discharge

The final shape is then cut to length by way of a flying cutoff press. This occurs seamlessly without stopping the roll forming process and will accurately cut to length per the design specifications. The final part will come out of the machine onto the run-out table to be stored or shipped.

You may add additional operations such as secondary punching or notching, end straightening, and so near the end of the roll forming line.

The above process shows how a roll-forming line takes shape. If you are looking for a high-quality, reliable roll forming machine to enhance your business operations, browse the range from Rollforming LLC or get in touch with your specifications today and we’ll find the ideal machine for you.

Posted on Thursday, January 4, 2024

B Deck is a common choice, there are other types of steel roof decks, such as A Deck, F Deck, and N Deck

Robotics and AI in sheet metal forming

Posted on Thursday, December 7, 2023

Robotics and AI in sheet metal forming offers numerous benefits, including increased efficiency, improved product quality

What is the history of roll forming machine?

Posted on Tuesday, November 28, 2023

Here is a brief history of the roll forming machine