Designing Your Profile For A New Roll Forming Machine

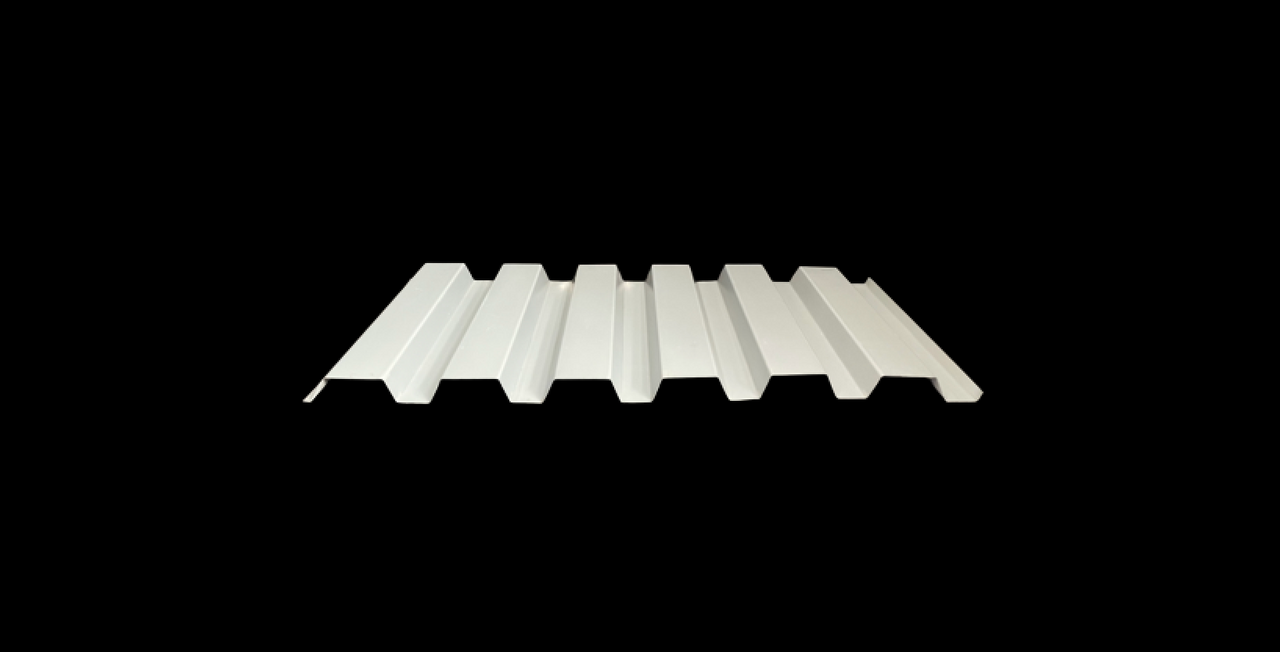

When designing your profile for a new roll-forming machine, several key factors must be considered to ensure a successful outcome.

Posted on Tuesday, May 9, 2023

Here are some tips to guide you in designing your new profile:

Material selection

Choose the appropriate material for your application. To do this, you'll need to think about strength, flexibility, corrosion resistance, and cost.

Profile complexity

When it comes to designing a new roll-forming profile, simplicity is often best. The more complex the shape, the more difficult it may be to manufacture and the greater the risk of quality issues.

Roll tooling

Choose the appropriate roll tooling for your profile. Again, the factors to consider will include material thickness, profile shape, and the number of bends required.

Tolerance requirements

Determine the tolerance requirements for your profile. The tighter the tolerances, the more precise the manufacturing process must be.

Production rate

Consider the production rate needed for your application. This will help determine the appropriate machine size and speed.

Testing and validation

Test and validate the profile design before beginning production. This will help ensure that the final product meets your specifications and quality standards.

Safety considerations

Ensure that the profile design and machine operation are safe for operators and comply with relevant safety standards.

Overall, careful planning and attention to detail are key to designing a successful profile for a new roll-forming machine. Consult with experts in the field to help you achieve the best possible outcome.

Designing a profile for a new roll-forming machine - why bother?

Designing a profile for a new roll-forming machine offers several benefits, including:

Customization

Designing your profile allows you to create a product customized to your specific needs and requirements.

Cost savings

A tailored profile will ensure that you optimize the use of materials, reducing waste and costs.

Greater precision

A custom-designed profile can be manufactured with greater precision, resulting in higher quality products and less waste.

Faster production

A well-designed profile can be manufactured more quickly, increasing production rates and reducing lead times.

Competitive advantage

A unique profile can give you a competitive edge in the market, differentiating your products from those of your competitors or allowing you to become more efficient or produce better quality products at more cost-effective pricing.

Flexibility

A custom-designed profile can be adjusted and modified as needed to adapt to changes in your production requirements or customer needs.

Improved product performance

A profile designed specifically for your application can improve product performance and customer satisfaction.

Overall, designing a profile for a new roll-forming machine offers numerous benefits that can help increase efficiency, reduce costs, and improve product quality and performance.

Are you looking for a roll-forming machine for your business?

If you are looking for a top-quality roll-forming machine for your business, why not browse the range of reliable machines from Roll Forming LLC? If you are still determining what you are looking for or have any questions, contact our knowledgeable team - we'd love to hear from you.

Posted on Thursday, January 4, 2024

B Deck is a common choice, there are other types of steel roof decks, such as A Deck, F Deck, and N Deck

Robotics and AI in sheet metal forming

Posted on Thursday, December 7, 2023

Robotics and AI in sheet metal forming offers numerous benefits, including increased efficiency, improved product quality

What is the history of roll forming machine?

Posted on Tuesday, November 28, 2023

Here is a brief history of the roll forming machine