Tube Mill Line & Pipe Mill Line Machines

Get a Quote

Send us a message and we’ll get back to you shortly.

Tube Mill Line & Pipe Mill Line Machine Description

We provide solutions to company's who manufacture pipes of different shapes and materials

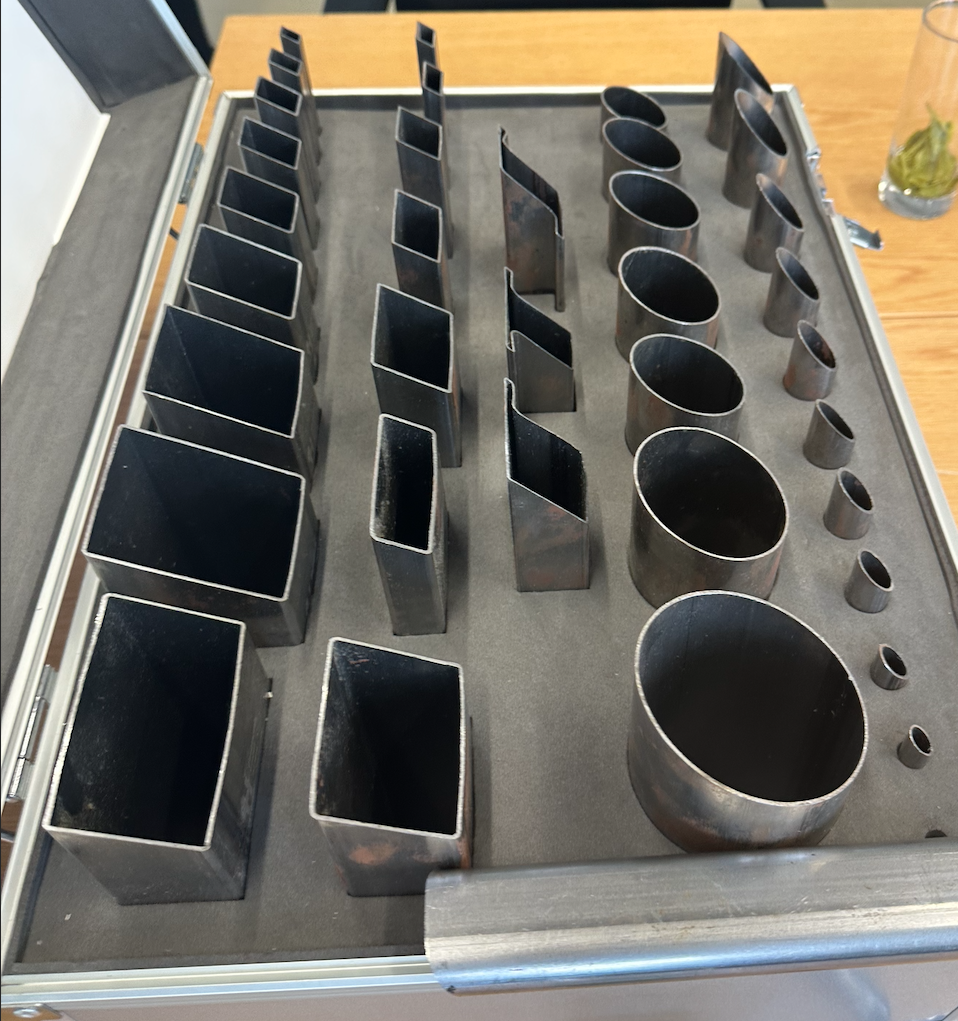

ROLLER QUICK CHANGE SYSTEM

The roller quick change system is suitable for the production of multiple sizes of steel tubes on a single tube mill production line. It only takes 10 minutes to change the roller, and production resumes within 20 minutes.

FLYING SAW CUT OFF EQUIPMENT

We have two kinds of steel pipe flying cut off saw machine: cold flying saw and hot flying saw.

AUTOMATIC STACKING & STRAPPING MACHINE

Automatic stacking and strapping machine is the last link of the steel pipe mill production line, which is used to arrange and pack the finished pipes in an orderly manner.

Tube mills and pipe mills are industrial machines used in the manufacturing of pipes and tubes. These machines are commonly used in the construction, automotive, and manufacturing industries to produce a wide range of pipes and tubes for various applications. Roll forming machines are a key component of tube and pipe mills, as they play a crucial role in shaping and forming the metal into the desired pipe or tube profiles.

Here's a brief overview of these machines:

- Tube Mill:

- A tube mill is a machine used to manufacture round or square tubes from flat metal strips or coils. The process typically involves the following steps: a. Uncoiling: The metal coil is unwound and fed into the tube mill. b. Forming: Roll forming stands or rolls shape the flat metal into a cylindrical or square shape. c. Welding: The edges of the metal strip are welded together to create a continuous seam along the length of the tube. d. Sizing: The tube is passed through sizing or shaping rolls to achieve the desired dimensions. e. Cut-off: The tube is cut to the required length.

- Tube mills are used to produce a wide variety of tubes, including structural, mechanical, and precision tubes used in different industries.

- Pipe Mill:

- A pipe mill is similar to a tube mill but is typically used to manufacture pipes with larger diameters and thicker walls. Pipe mills are commonly used for producing pipes used in the oil and gas industry, water distribution, and structural applications.

- The manufacturing process in a pipe mill is similar to that of a tube mill but is adapted to handle larger and heavier materials.

- Roll Forming Machine:

- Roll forming machines are used in both tube mills and pipe mills to shape the metal into the desired cross-sectional profile. They consist of a series of rolls that progressively bend and form the metal strip into the desired shape.

- Roll forming is a continuous process that allows for high precision and consistency in the production of tubes and pipes.

- The design of the rolls in a roll forming machine can be customized to produce various shapes and sizes of tubes and pipes.

In summary, tube mills and pipe mills are used to manufacture tubes and pipes, respectively, and roll forming machines are a critical component of these mills, helping to shape the metal into the desired profiles. These machines are essential for the production of various types of pipes and tubes used in a wide range of applications