Stud and Track Roll Forming Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Stud and Track Machine Roll Forming Machine Specifications

- Stud and Track Machine with auto packing and stacking system.

- Can produce profiles between 75mm to 150mm

- Flying shear

- Embossing - stamping

- Safety covers are with hydraulic lift up doors and sliding doors for easy access

Stud and Track Machine Roll Forming Machine Description

A stud and track roll forming machine is a type of industrial machinery used in the construction and building industry to manufacture metal studs and tracks, which are commonly used in framing walls, ceilings, and partitions. These machines are designed to take coil or sheet metal, typically made of steel or other metals, and transform it into specific shapes and sizes of studs and tracks through a continuous roll forming process.

Here's how a stud and track roll forming machine typically works:

- Material Loading: The process starts by loading a coil or sheet of metal onto the machine. The machine may have a decoiler to unwind the coil or a feeding mechanism to handle the sheet metal.

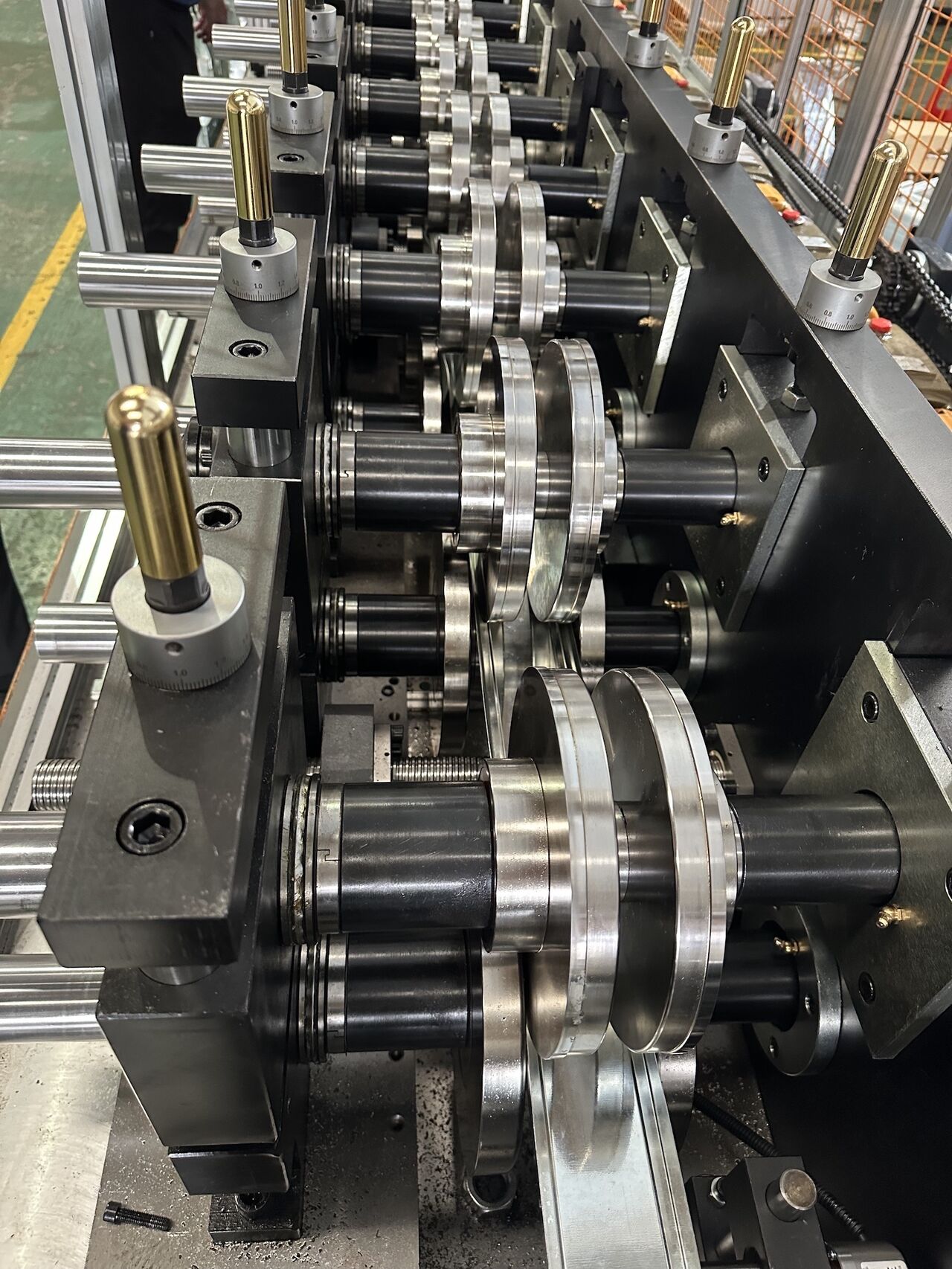

- Roll Forming: The metal passes through a series of rollers, each with a specific profile, which gradually shapes the metal into the desired stud or track profile. These rollers are typically arranged in pairs, with each pair performing a specific bending or forming operation.

- Cutting: At specific intervals, the machine includes a cutting mechanism that cuts the continuous metal strip into individual studs or tracks of the desired length. The cutting mechanism can be mechanical or hydraulic, depending on the machine's design.

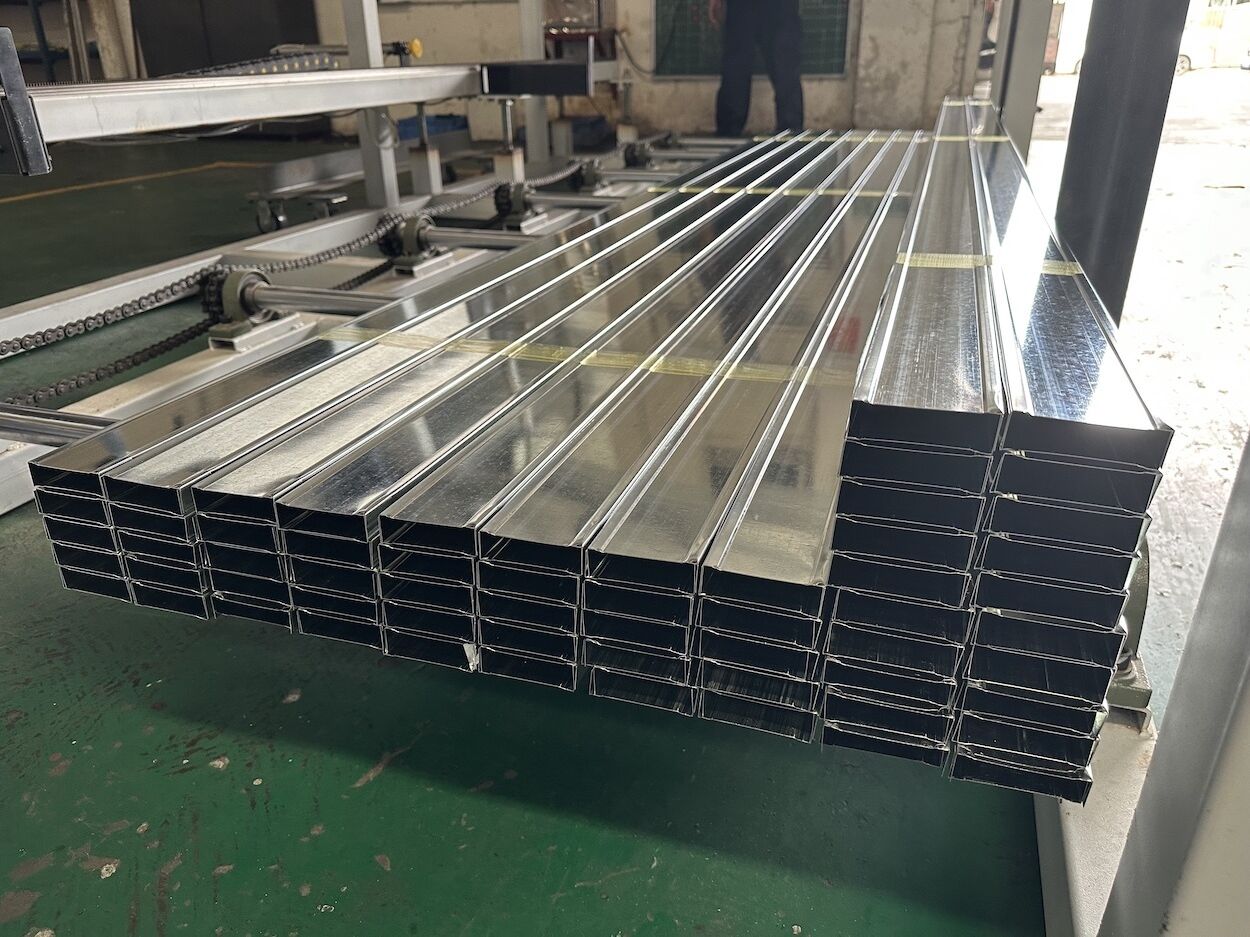

- Stacking and Collection: After cutting, the finished studs and tracks are typically collected and stacked for easy handling and transportation.

- Optional Features: Some stud and track roll forming machines may include additional features, such as hole punching or embossing, to create specific patterns or configurations on the studs and tracks.

The specifications of a stud and track roll forming machine can vary depending on the requirements of the construction project and the type of studs and tracks being produced. These machines can produce different profiles and sizes of studs and tracks to meet the specific needs of the construction industry.

Stud and track roll forming machines are known for their efficiency, precision, and the ability to produce large quantities of framing materials quickly. They are commonly used in the construction of residential and commercial buildings, as well as in industrial settings where partition walls and ceilings need to be erected.

It's worth noting that there are various manufacturers and models of stud and track roll forming machines available in the market, each with its own set of features and capabilities to cater to different production needs.