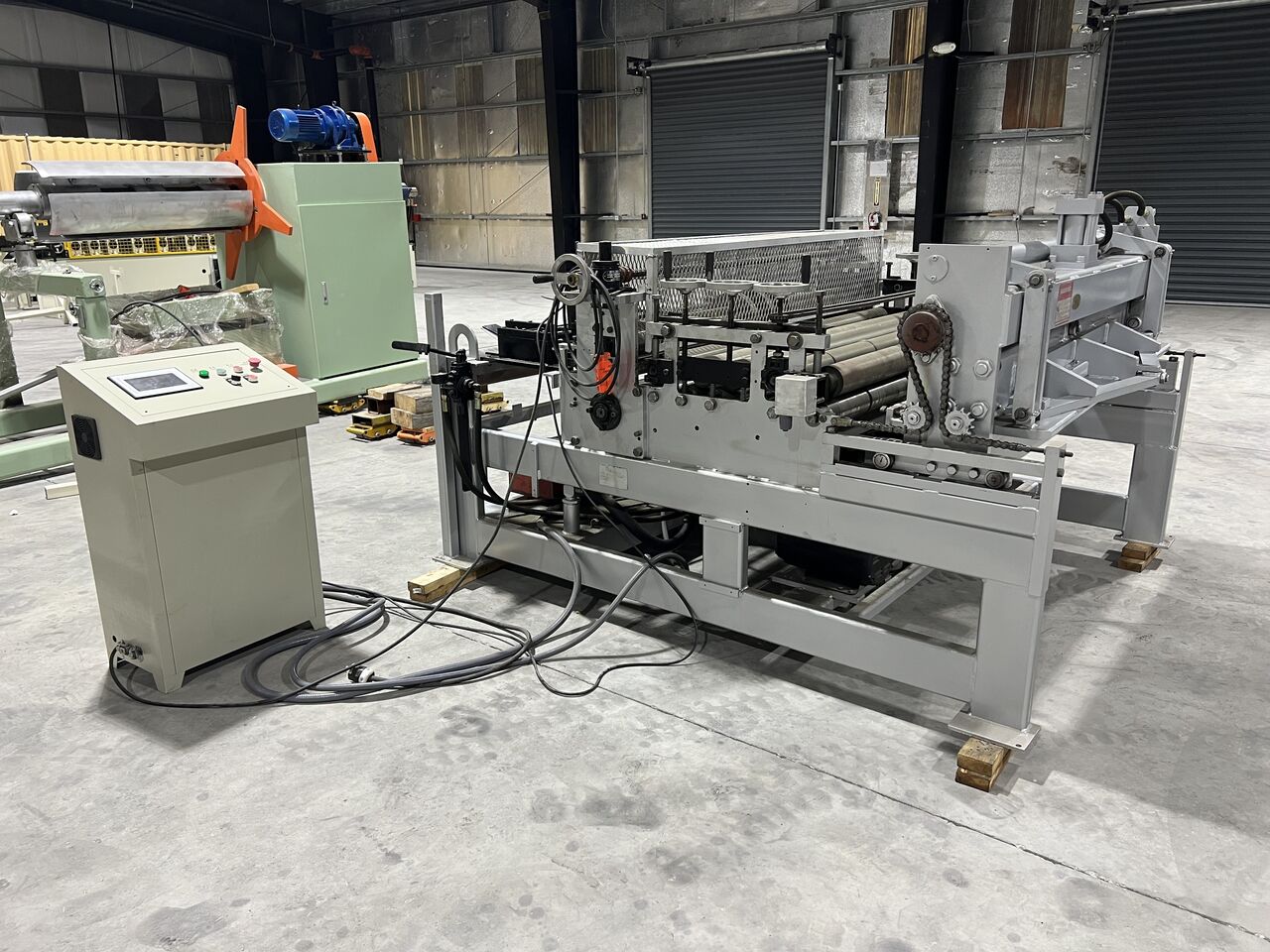

Slitter Line Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Metal slitting machine Specifications

- Restored slitter line

- new control cabinet

- 16g 60" cut to length line

- straightening rollers

Metal slitting machine Description

Metal slitting machines are specialized industrial machines used in the metalworking and manufacturing industries to cut large metal coils into narrower strips or coils of smaller width. These machines are essential for processing raw metal coils into more manageable and usable sizes for various applications, such as automotive parts, construction materials, and metal fabrication.

Here are some key features and components of metal slitting machines:

- Uncoiler: The process begins with an uncoiler, which holds the large metal coil and feeds it into the slitting machine. Uncoilers can be manual or automatic, depending on the machine's design and capacity.

- Straightening and leveling: Some slitting machines have straightening and leveling units to ensure that the metal strip is flat and even before it goes through the slitting process. This step improves the accuracy of the final slit strips.

- Slitter head: The heart of the slitting machine is the slitter head, which consists of multiple sets of circular blades or rotary knives. These blades make precision cuts along the width of the metal coil, creating narrower strips. The number of blades and their spacing can be adjusted to produce strips of different widths.

- Recoiler: After the metal coil has been slit into smaller strips, the recoiler winds the individual strips into coils of the desired size. Recoilers can also be manual or automatic and may include tension control systems to ensure proper winding.

- Scrap winder: During the slitting process, some material on the edges of the coil, known as trim or scrap, is removed. A scrap winder collects and compresses this scrap material for recycling or disposal.

- Control system: Modern metal slitting machines are equipped with computerized control systems that allow operators to set parameters such as strip width, cutting speed, and tension control. These systems help ensure precise and consistent results.

- Safety features: Safety is a crucial consideration in the operation of metal slitting machines. They often include safety guards, emergency stop buttons, and sensors to detect abnormalities or hazards during operation.

Metal slitting machines come in various sizes and configurations to accommodate different types of metal coils and production requirements. Some machines are designed for light-duty applications, while others are built for heavy-duty and high-speed processing.

The choice of a metal slitting machine depends on factors like the type and thickness of the metal to be slit, the required strip width, and the production volume. Proper maintenance and operator training are essential to ensure the machine's longevity and safe operation.