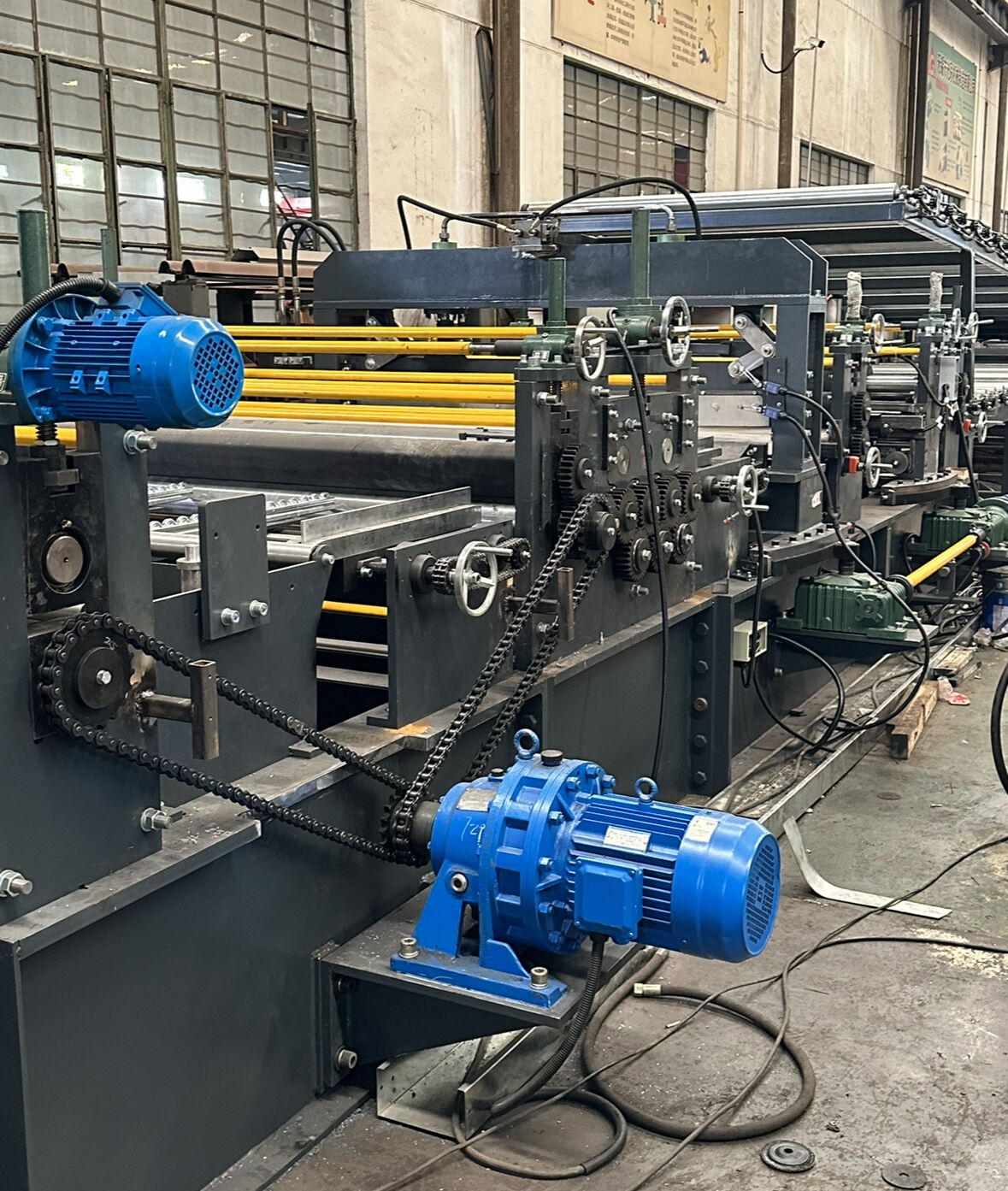

Silo Roof Roll Forming Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Silo Roof Roll Forming Machine Description

A silo roof roll forming machine is a specialized piece of equipment used in the construction and manufacturing of silos, which are storage containers typically used in agriculture and industry to store bulk materials such as grains, cement, coal, and more. The primary function of a silo roof roll forming machine is to produce the roof panels or sheets that cover the top of the silo, providing protection from the elements and helping to maintain the quality of the stored materials.

Here's how a typical silo roof roll forming machine works:

- Material Feed: The machine starts by feeding in a continuous roll of metal sheet material, often made of galvanized steel or another durable material. This material will be used to form the roof panels.

- Roll Forming Process: The roll forming machine uses a series of rollers and dies to gradually shape the flat metal sheet into the desired profile for the silo roof panels. This typically involves a series of bends, folds, and shaping operations to create the corrugated or other specific profile required for the roof.

- Cutting and Shearing: Once the metal sheet has been formed into the desired shape, the machine includes cutting and shearing mechanisms to trim the panels to the appropriate length and shape. This ensures that the panels fit together properly and cover the entire top of the silo.

- Stacking and Collection: After the roof panels are cut to size, they are often stacked or collected in bundles for transportation to the construction site.

- Installation: At the construction site, the roof panels produced by the silo roof roll forming machine are assembled and attached to the top of the silo structure, completing the silo's enclosure.

These machines are highly specialized and can produce roof panels of various sizes and profiles to meet the specific requirements of different types of silos. They help streamline the manufacturing process, making it more efficient and cost-effective for companies involved in silo construction and maintenance.

In summary, a silo roof roll forming machine is an essential piece of equipment used in the production of roof panels for silos, contributing to the durability and functionality of these storage structures.