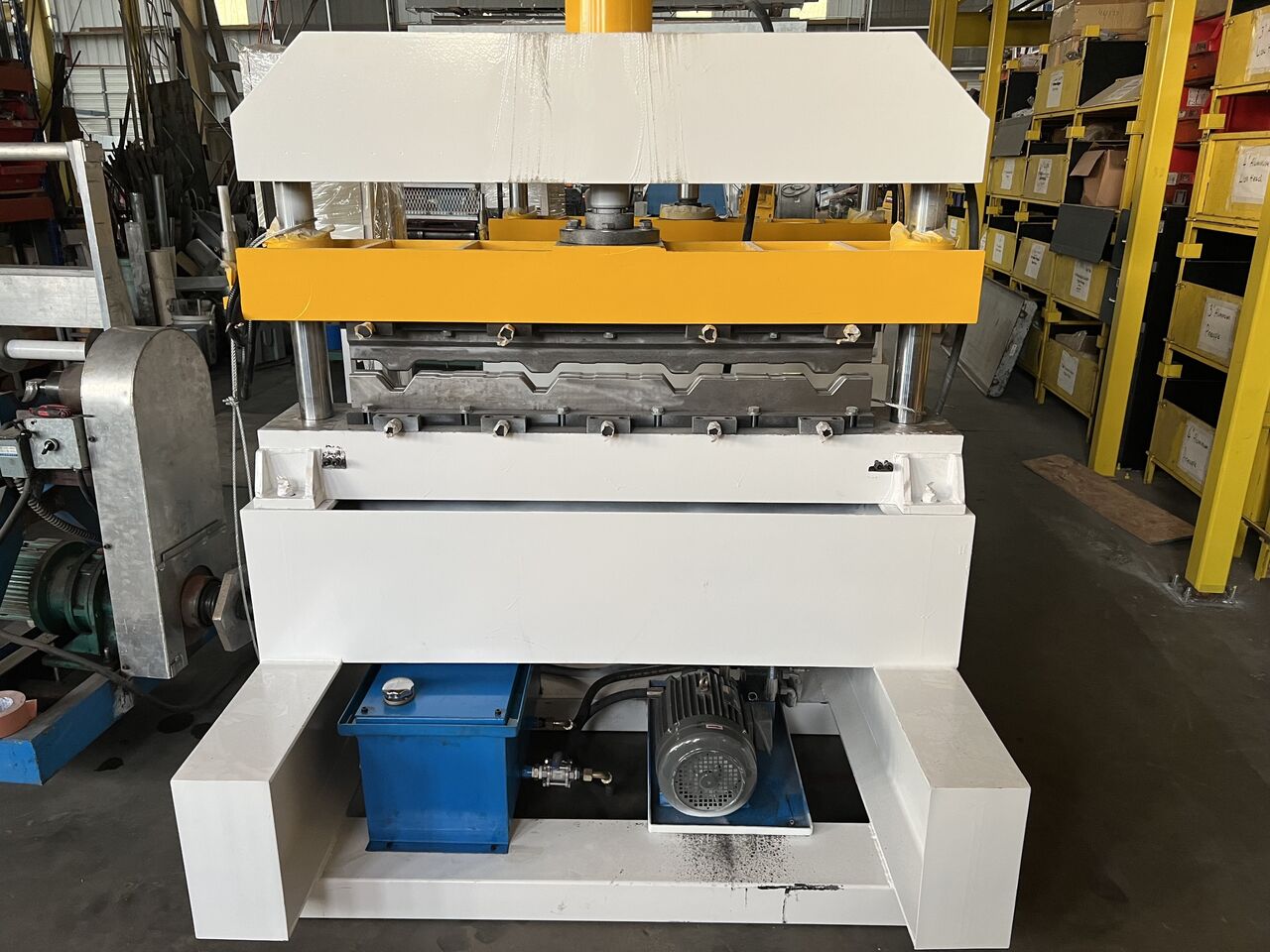

Ridge Cap Bender Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Metal Ridge Cap Bending Machine Specifications

- Manually Adjustable Depth Control for Different Pitches

- Operated via Foot Switch

- Material thickness: 24g to 29g

- Panel width: 36" wide

- Pitch 1 - 12 to 4 - 12 Max

- Profile - Pbr - AG

- Machine Weight - 1400lbs

- Machine Footprint - 70” height 70” x 60 deep

- Main power - 240v - 3ph - 60Hz

- Ridge cap production speed: 4 ridge caps per minute

Metal Ridge Cap Bending Machine Description

A metal ridge cap bending machine is a specialized piece of equipment used in the roofing and construction industry. Its primary function is to bend and shape metal materials into ridge caps, which are components used to cover the peak of a roof where two sloping sides meet. Ridge caps not only provide a finished look to the roof but also serve as a protective barrier against water infiltration.

Here are some key features and functions of a typical metal ridge cap bending machine:

- Material Compatibility: These machines are designed to work with various types of metal materials commonly used in roofing, such as galvanized steel, aluminum, copper, or zinc-coated steel.

- Bending Mechanism: Ridge cap bending machines use hydraulic or mechanical mechanisms to bend the metal sheets into the desired shape. The machine can be programmed or adjusted to create ridge caps of different dimensions and profiles.

- Precision and Consistency: They are capable of producing ridge caps with precise angles and consistent shapes, ensuring uniformity in the final product.

- Speed and Efficiency: These machines can bend metal quickly and efficiently, which is essential in commercial roofing projects where time is of the essence.

- Safety Features: Safety measures are typically integrated into these machines to protect operators from accidents, such as pinch points and safety guards.

- Customization: Depending on the specific needs of a project, ridge cap bending machines can be set up to create different ridge cap profiles, including varying angles and lengths.

- Portability: Some models of ridge cap bending machines are designed to be portable, allowing for easier transportation to job sites.

- Automation: Advanced machines may feature automation capabilities, such as computer numerical control (CNC) systems, which can enhance precision and reduce the need for manual adjustments.

- Maintenance: Regular maintenance is essential to keep the machine in good working condition and ensure the quality of the ridge caps it produces.

These machines are typically used by roofing contractors and sheet metal fabricators to create custom ridge caps for various roofing projects. The specific features and capabilities of a metal ridge cap bending machine can vary depending on the manufacturer and model, so it's essential to choose one that suits the requirements of your particular project or business. Additionally, proper training and safety precautions should be observed when operating such machinery to prevent accidents and ensure quality results.

All roll forming machinery is fully assembled at our factory in Orlando Florida. and comes with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

To request a quote or If you have any questions about our machines, please fill out the contact form below.