Quad Wall Panel Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Multiple Rib Pattern ( Quad )Roll Forming Machine Specifications

- Coil Width:

- Profile size:

- Forming Speed:

- Material thickness:

- Machine Weight:

- Machine Footprint:

- Main power: 240v - 3ph - 60Hz

- Stations:

- Cutting type:

- Control system:

- Safety covers: yes

- E Stops

- FOB Orlando, Florida

All roll forming machinery is fully assembled at our factory in Orlando Florida. Our Roll Forming Machines come with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

Multiple Rib Roll Forming Machine Description

A Metal Wall Panel & Siding Roll Forming Machine is a piece of equipment used in the manufacturing process of metal wall panels and siding materials. Roll forming is a metalworking process that involves shaping flat metal sheets or coils into desired profiles by passing them through a series of rollers.

Here's an overview of how a Metal Wall Panel & Siding Roll Forming Machine works:

- Material Feeding: The process begins with a coil of metal, typically steel or aluminum, which is loaded onto the machine. The coil is mounted on a decoiler, which gradually feeds the metal into the roll forming machine.

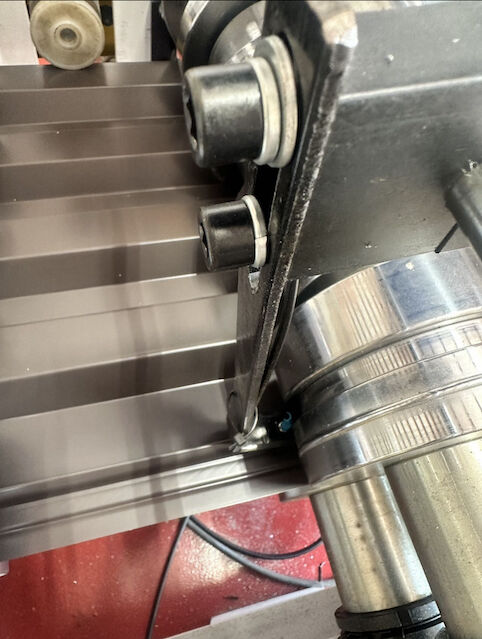

- Roll Forming: The metal sheet passes through a series of rollers, each of which is designed to bend the metal incrementally to achieve the desired profile. In the case of wall panels and siding, these rollers are configured to create the ribbed or corrugated pattern that gives the panels their texture.

- Cutting: At specific points along the production line, there are cutting mechanisms that can trim the continuous metal sheet into the desired panel lengths. These cutters are often synchronized with the roll forming process to ensure accurate panel dimensions.

- Profile Customization: Roll forming machines can be customized to produce different profiles and patterns based on the design requirements of the wall panels and siding. The machine operator can adjust the settings to achieve the desired panel shape and dimensions.

- Material Coating: Some roll forming machines may include a coating or painting station, where a protective finish or color coating is applied to the metal panels as they are formed.

- Stacking or Packaging: After the panels are formed, cut, and coated (if applicable), they are typically stacked or packaged for shipping and distribution.

The advantages of using a Metal Wall Panel & Siding Roll Forming Machine include high efficiency, precision in producing consistent profiles, and the ability to manufacture panels in various lengths and profiles according to project requirements. These machines are commonly used in the construction industry to produce exterior cladding materials for buildings, including commercial, industrial, and residential structures.

Multiple Rib Metal Wall Panel & Siding Profile

- Design: These panels are characterized by multiple ribs or raised patterns on their surface. The ribs can vary in depth, spacing, and orientation, creating a distinctive visual texture. This textured appearance can enhance the aesthetic appeal of a building's exterior.

- Materials: They are typically made from metal, such as steel or aluminum. Metal panels are known for their durability, resistance to weathering, and low maintenance requirements.

- Functionality: Multiple rib pattern metal wall panels and siding offer several functional benefits, including:

- Strength: The ribbed design provides structural strength and rigidity to the building envelope.

- Water Management: The ribs may help channel water away from the building, reducing the risk of water infiltration and damage.

- Variety: They come in various profiles and colors, allowing for design versatility to match the architectural style of the building.

- Installation: These panels are designed for ease of installation. They can be attached to a building's framework using various methods, such as screws or clips, depending on the specific product.

- Applications: Multiple rib pattern metal wall panels and siding are commonly used in commercial and industrial buildings, but they can also be used in residential construction. They are versatile and suitable for both new construction and renovation projects.

- Maintenance: Metal siding is generally low maintenance, requiring periodic cleaning and inspections to ensure its integrity.

When considering multiple rib pattern metal wall panels and siding for a construction project, it's important to select a product that meets the specific requirements of the project in terms of aesthetics, weather resistance, insulation, and structural needs. Additionally, local building codes and regulations should be adhered to during installation.