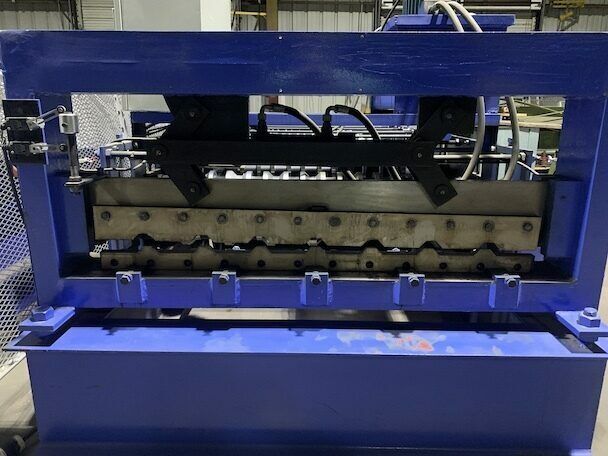

Pbu Rollformer

Get a Quote

Send us a message and we’ll get back to you shortly.

Pbu Roll Forming Machine Specifications

- Computer Control & Batching

- 43" wide coil

- 26 tp 29 g

- 7 Hp Motor 480v – 60Hz 3 Phase

- Safety Covers (13 Stations)

- Yasakawa Drive

- Hydraulic shear

- Manual 5 Ton Uncoiler

- E. Stops

- 22 ft x 5 ft x 5 ft

- Weight 3.5 Tons

Pbu Roll Forming Machine Description

A PBU (Panel Bearing Upright) Roll Forming Machine is a specialized piece of equipment used in the manufacturing and production of metal panels, specifically for constructing buildings and structures. Roll forming is a continuous metal forming process that transforms a flat metal sheet or coil into a desired profile or shape by passing it through a series of roll forming stations. The PBU roll forming machine is designed to produce PBU panels, which are commonly used as siding, roofing, and wall cladding in commercial and industrial buildings. Here is a brief description of a PBU Roll Forming Machine:

- Material Feeding System: The process begins with a material feeding system that uncoils and feeds a metal coil (typically steel or aluminum) into the machine. The coil can be of varying thickness and width, depending on the desired PBU panel specifications.

- Roll Forming Stations: The heart of the PBU roll forming machine consists of multiple roll forming stations arranged in a sequential order. Each station has sets of rollers that gradually shape the metal as it passes through. The rollers are precisely designed to create the specific profile of the PBU panel. These stations can include pre-punching, pre-cutting, and various forming rolls.

- Cutting Mechanism: In some PBU roll forming machines, there may be an integrated cutting mechanism that trims the formed panel to the desired length. Alternatively, a separate cutting station may be used after the roll forming process to cut the panel to the required size.

- Control System: Modern PBU roll forming machines are equipped with computerized control systems that allow operators to input panel specifications, monitor the production process, and make adjustments as needed. These systems help ensure precise and consistent panel production.

- Material Handling: Once the PBU panels are formed and cut to the required lengths, they are typically stacked and conveyed for further processing, packaging, or shipping.

PBU panels produced by these machines are known for their strength, durability, and versatility. They are commonly used in the construction industry due to their ease of installation, weather resistance, and aesthetic appeal. The specific design and features of a PBU roll forming machine can vary depending on the manufacturer and the requirements of the end-user.

Pbu Roll Forming Profile

The term "PBU Roll Forming Profile" likely refers to the specific shape or design of a metal panel that is produced using a PBU (Panel Bearing Upright) roll forming machine. PBU panels are commonly used in the construction industry as siding, roofing, and wall cladding for commercial and industrial buildings. The profile of a PBU panel can vary depending on the manufacturer and the specific requirements of a construction project, but here is a general description of a typical PBU roll forming profile:

- Ribbed or Corrugated Design: PBU panels typically have a ribbed or corrugated profile, which provides structural strength and rigidity to the panel. These ribs are raised portions of the panel that run horizontally across its surface. The corrugations not only enhance the panel's strength but also add a distinctive visual texture.

- Trapezoidal Shape: PBU panels often have a trapezoidal shape when viewed in cross-section. This shape is characterized by two sloping sides that meet at a flat top. The trapezoidal design makes it easier to interlock and install the panels, ensuring a secure fit that helps with weather resistance.

- Overlapping Edges: PBU panels are designed to overlap each other when installed, creating a weather-tight seal. The overlapping edges typically have specially designed features, such as male and female ribs or interlocking profiles, to facilitate this secure connection.

- Material and Coating: PBU panels can be made from various materials, such as steel or aluminum, depending on the desired strength and durability. They are often coated with protective finishes like paint or galvanized coatings to enhance corrosion resistance and prolong their lifespan.

- Length and Width: The length and width of PBU panels can vary depending on the specific requirements of a construction project. Roll forming machines are typically designed to produce panels of varying lengths to accommodate different building dimensions.

- Color and Finish: PBU panels are available in a range of colors and finishes to match the aesthetic preferences of the building owner or architect. Common colors include various shades of white, gray, blue, green, and more.

It's important to note that the exact profile and specifications of PBU panels can vary between manufacturers and regions. These panels are known for their durability, ease of installation, and ability to provide weather protection and insulation to buildings. Builders and contractors often choose PBU panels for their versatility and cost-effectiveness in commercial and industrial construction projects.