Ex Demo Multi Trim Roll Forming Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Triple Trim Roll Forming Machine Description

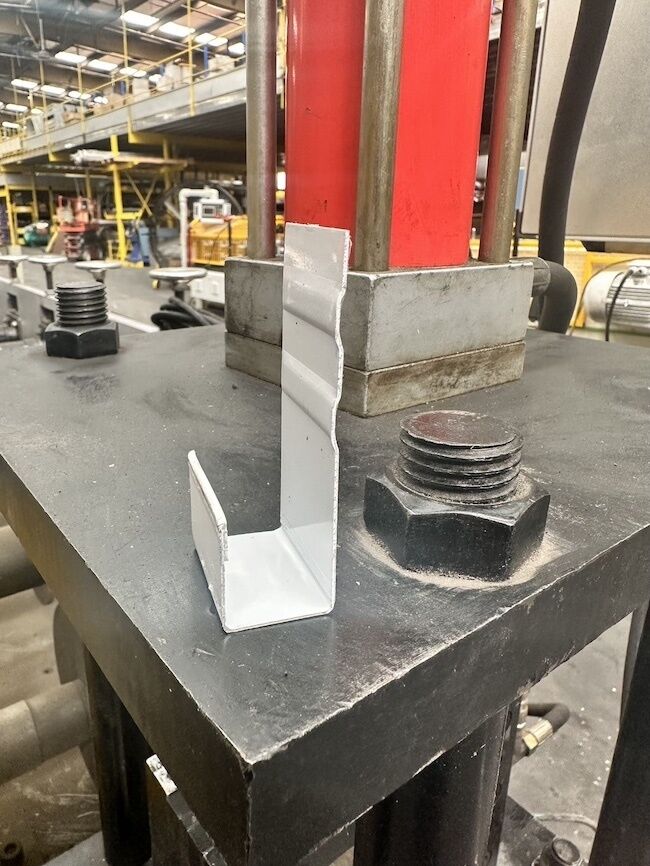

Profiles

- J trim

- Ridge Cap

- Corner Trim

A Triple Trim Roll Forming Machine is a specialized piece of industrial equipment used in the metalworking industry for shaping and forming metal strips or coils into specific profiles. Roll forming is a continuous and highly efficient process that involves passing a continuous metal strip through a series of rollers to gradually bend it into the desired shape.

The term "Triple Trim" likely refers to a machine with three sets of forming rollers or stations, allowing for the simultaneous creation of three different profiles or shapes from a single metal strip. This can be especially useful in situations where multiple parts or components with different profiles need to be produced from the same material.

The key components and features of a Triple Trim Roll Forming Machine typically include:

- Entry Section: This is where the metal strip or coil is loaded onto the machine. It may include decoilers and other equipment to ensure the smooth feeding of the material into the forming process.

- Roll Forming Stations: These are the heart of the machine and consist of a series of rollers, which can be adjustable to create specific profiles. In a Triple Trim machine, there are three sets of forming stations to produce three different profiles simultaneously.

- Cutting Mechanisms: To separate the formed profiles into individual parts or components, the machine may have cutting or shearing mechanisms that can trim the material to the desired lengths.

- Control System: Modern roll forming machines are equipped with computerized control systems that allow operators to set parameters such as roller positions, feed rates, and cut lengths. This ensures precision and consistency in the production process.

- Exit Section: Once the metal strip has passed through the forming and cutting stations, the finished parts are typically conveyed away from the machine for further processing or packaging.

Triple Trim Roll Forming Machines are used in various industries, including automotive, construction, aerospace, and appliance manufacturing, among others. They are versatile and efficient for producing a wide range of metal profiles, such as C-channels, Z-purlins, door frames, roof panels, and more. The ability to produce multiple profiles simultaneously can increase productivity and reduce material waste, making them valuable tools in metal fabrication and manufacturing processes.