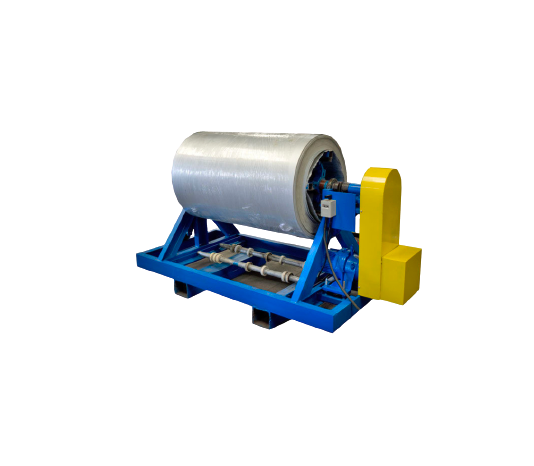

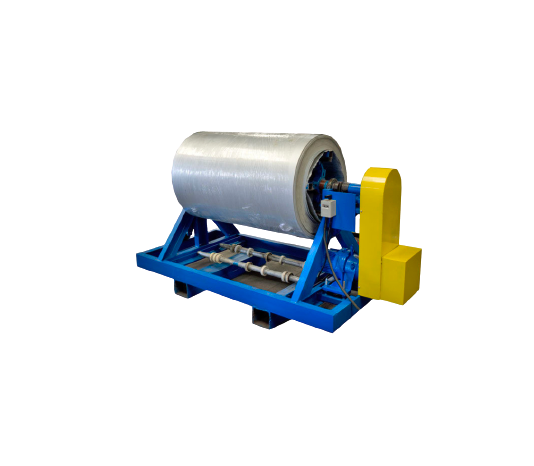

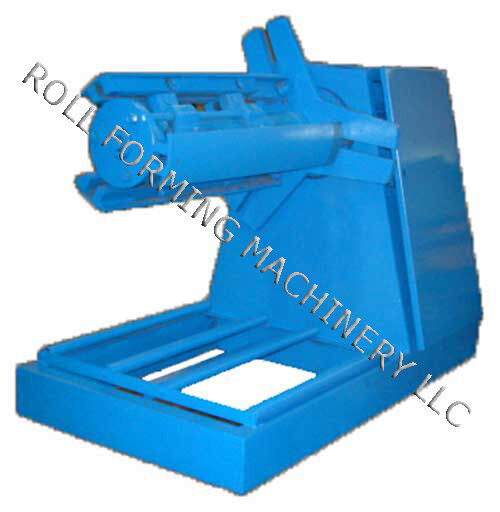

Decoiler - Uncoiler Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

We stock many Decoilers contact for latest stock and specs

An uncoiler machine, also known as a decoiler or unwinding machine, is a piece of industrial equipment used in various manufacturing processes, particularly in metalworking and coil processing industries. Its primary function is to unwind and feed a coiled material, such as metal coils, wire, or strips, into downstream processes, such as stamping, roll forming, or shearing. This allows for continuous and automated production without the need for manual handling of the coiled material.

Key features and components of an uncoiler machine may include:

- Mandrel or Spindle: The mandrel or spindle is a central shaft onto which the coil is mounted. It provides support and ensures that the coil unwinds smoothly.

- Coil Holding Mechanism: This mechanism holds the coiled material securely in place on the mandrel, preventing it from uncoiling prematurely.

- Decoiling Mechanism: The uncoiling process is controlled by a motor or other power source that rotates the mandrel. This action unwinds the coil, allowing the material to feed into the production line.

- Tension Control: Some uncoiler machines have tension control systems to maintain consistent tension on the material as it is fed into downstream processes. This helps prevent issues like wrinkles or buckling in the material.

- Coil Brake and Drive System: To control the speed and tension of the unwinding material, uncoilers may have a brake system to slow down or stop the unwinding process when necessary. A drive system, often consisting of motors and gears, provides the necessary power to rotate the mandrel.

- Coil Loading and Unloading: Some uncoiler machines come with features for easy loading and unloading of coils. This can include hydraulic or pneumatic lift mechanisms.

- Coil Centering and Alignment: Ensures that the coil is properly centered and aligned for smooth unwinding.

- Safety Features: Uncoiler machines typically include safety features such as guards, emergency stop buttons, and sensors to protect operators and prevent accidents.

The choice of an uncoiler machine depends on various factors, including the type and size of the coiled material, the production rate, and the specific requirements of the manufacturing process. Uncoiler machines are commonly used in industries such as automotive manufacturing, steel processing, metal stamping, and more, where they play a crucial role in ensuring efficient and continuous production.

All roll forming machinery is fully assembled at our factory in Orlando Florida. and comes with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

To request a quote or If you have any questions about our machines, please fill out the contact form below.