AG Panel Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

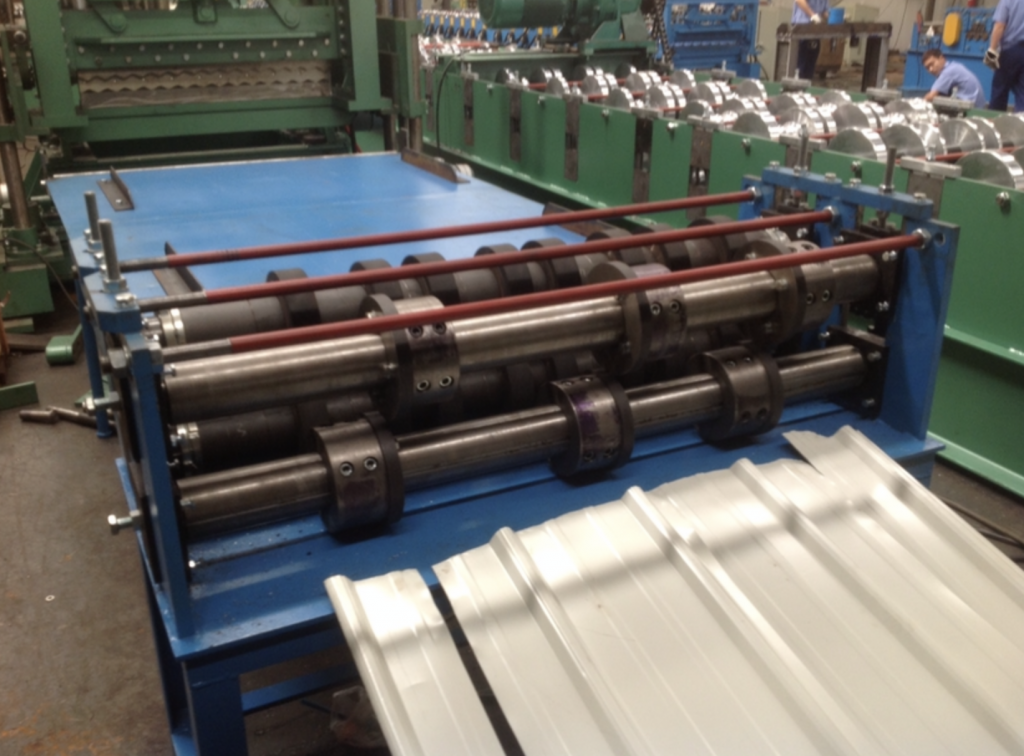

New AG Roof Panel Roll Forming Machine Specifications

- 40 feet long 5 feet wide

- 24g to 29g

- Pre Shear

- Computer batching

- 18 stands

- Heavy Duty rollers

- Heavy Duty motor

- chain drive

- E stops and safety covers

- Read out in inches

- Used with 10,000lb Uncoiler with car

All roll forming machinery is fully assembled at our factory in Orlando Florida. Our Roll Forming Machines come with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

AG Roof Panel Roll Forming Machine Description

An AG Roof Panel Roll Forming Machine is a piece of equipment used in the construction industry to manufacture roof panels from metal coils. Roll forming is a continuous process that shapes a flat metal strip into a desired profile or shape by passing it through a series of rollers. In the case of roof panels, this machine is specifically designed to create the corrugated or other profiles commonly used in roofing applications.

Here's how a typical AG Roof Panel Roll Forming Machine works:

- Material Loading: Metal coils, typically made of steel or aluminum, are loaded onto the machine. These coils serve as the raw material for producing the roof panels.

- Uncoiling: The metal coil is uncoiled as it is fed into the machine. This step ensures a continuous supply of material to the forming process.

- Roll Forming: The metal strip passes through a series of rollers and dies that gradually shape it into the desired profile. The rollers are configured to bend and shape the metal according to the specific design of the roof panel. In the case of AG panels, which are commonly used in agricultural and industrial buildings, the machine forms a series of corrugations or waves.

- Cutting: Once the desired length of roof panel has been formed, the machine may have a cutting mechanism that trims the panel to the appropriate size. Some machines have a flying cutoff system, allowing for continuous production.

- Stacking or Packaging: The finished roof panels are either stacked or packaged for storage and transportation. They may also be labeled or marked with relevant information, such as length, profile type, or manufacturing date.

AG Roof Panel Roll Forming Machines come in various sizes and configurations to accommodate different panel profiles and production capacities. These machines play a crucial role in the construction industry, allowing for efficient and cost-effective manufacturing of roof panels that are durable and weather-resistant.

The specific features and capabilities of AG Roof Panel Roll Forming Machines can vary from one manufacturer to another, so it's essential to consider your production needs and the desired panel specifications when selecting one for your roofing project.

AG Panel Metal Roof Profile

The AG Panel is a popular metal roof profile used in various construction applications, particularly in agricultural and industrial buildings. It is known for its durability, cost-effectiveness, and versatility. The "AG" in AG Panel typically stands for "Agricultural," but it has found use in many other contexts as well due to its practical design.

Here are some key characteristics and features of the AG Panel metal roof profile:

- Corrugated Design: The AG Panel features a corrugated or ribbed design, with a series of continuous, closely spaced waves or ribs running along the length of the panel. This design enhances the panel's strength and rigidity while also providing effective water drainage.

- Material Options: AG Panels are commonly made from galvanized steel, which offers excellent corrosion resistance. They may also be available in other materials like aluminum or coated steel for added durability and longevity.

- Versatility: AG Panels are versatile and can be used in a wide range of applications, including agricultural buildings (such as barns and storage sheds), industrial facilities, commercial structures, and residential roofing.

- Length and Width Variations: AG Panels come in various lengths and widths to accommodate different roofing and siding needs. The standard width of an AG Panel is typically around 36 inches.

- Ease of Installation: AG Panels are relatively easy to install due to their design. They often have overlapping ribs or seams that provide a secure fit, helping to prevent leaks and ensuring a watertight seal when properly installed.

- Weather Resistance: The corrugated design of AG Panels helps channel rainwater and snowmelt away from the roof's surface, reducing the risk of water infiltration and minimizing the weight on the roof.

- Cost-Effective: AG Panels are known for their cost-effectiveness, making them a popular choice for budget-conscious construction projects.

- Color Options: These panels are often available in a variety of colors and finishes, allowing for customization to match the aesthetics of the building.

- Longevity: When properly maintained, AG Panel roofs can have a long service life, providing decades of protection and insulation.

Overall, the AG Panel metal roof profile is valued for its practicality, durability, and cost-effectiveness. It is suitable for a range of applications and can be a reliable choice for roofing and siding needs in various construction projects. When considering the use of AG Panels, it's essential to consult with manufacturers or suppliers to determine the specific options available, such as material choices, colors, and profile variations, to best meet your project requirements.