3" N Deck Roll Forming Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Cassette Machine Decking Roll Forming Machine Specifications

- Footprint 120ft x 15ft

- Profiles: 3" N Deck - 3" Composite

- 20,000lb Uncoiler

- 16g - 22g

- 480v - 3ph - 60Hz

- Gear box drive

- 28 stands

- Pre Flying shear

- Footprint 120ft x 15ft

- coil width 48" +/-

3" N Deck Machine Description

A 3" N Deck Roll Forming Machine is a piece of industrial equipment used in the construction and manufacturing industry to produce N Deck roof or floor decking panels. N Deck is a type of steel decking commonly used in commercial and industrial building construction. It provides structural support and serves as a base for roofing or flooring materials.

Here are some key features and information about a 3" N Deck Roll Forming Machine:

- Roll Forming Process: Roll forming is a metal shaping process that involves passing a metal strip or coil through a series of rollers to gradually shape it into a specific profile or cross-section. In the case of N Deck panels, the roll forming machine shapes the steel into the desired profile with a 3-inch depth.

- Material: These machines are typically designed to work with various gauges of steel, depending on the specific requirements of the project. The steel is usually coated with galvanized or other protective coatings to enhance durability and resistance to corrosion.

- Profile Specifications: The 3" N Deck profile refers to the depth of the deck, which is 3 inches. The width and other specifications of the N Deck panel may vary depending on the machine's design and the customer's requirements.

- Speed and Production Capacity: The production speed and capacity of a 3" N Deck Roll Forming Machine can vary depending on its design and the complexity of the profile. These machines are capable of high-speed production to meet the demands of large-scale construction projects.

- Automation: Modern roll forming machines are often equipped with automation features that make the operation more efficient and reduce the need for manual labor. This can include automatic coil feeding, cutting, and stacking mechanisms.

- Customization: Roll forming machines can be customized to produce different profiles and sizes of decking panels to meet the specific needs of construction projects.

- Safety: Safety features are an important aspect of roll forming machines to ensure the well-being of operators and workers. These features may include emergency stop buttons, safety guards, and safety interlocks.

- Applications: N Deck panels produced by these machines are commonly used in various construction applications, including roofing, flooring, and mezzanine systems in industrial and commercial buildings.

It's important to note that specific details about a 3" N Deck Roll Forming Machine, such as its exact specifications and capabilities, can vary from one manufacturer to another. If you are considering purchasing or using such a machine, it's essential to consult with the manufacturer or supplier to get detailed information about the specific model you are interested in. Additionally, operators of these machines should receive proper training to ensure safe and efficient operation.

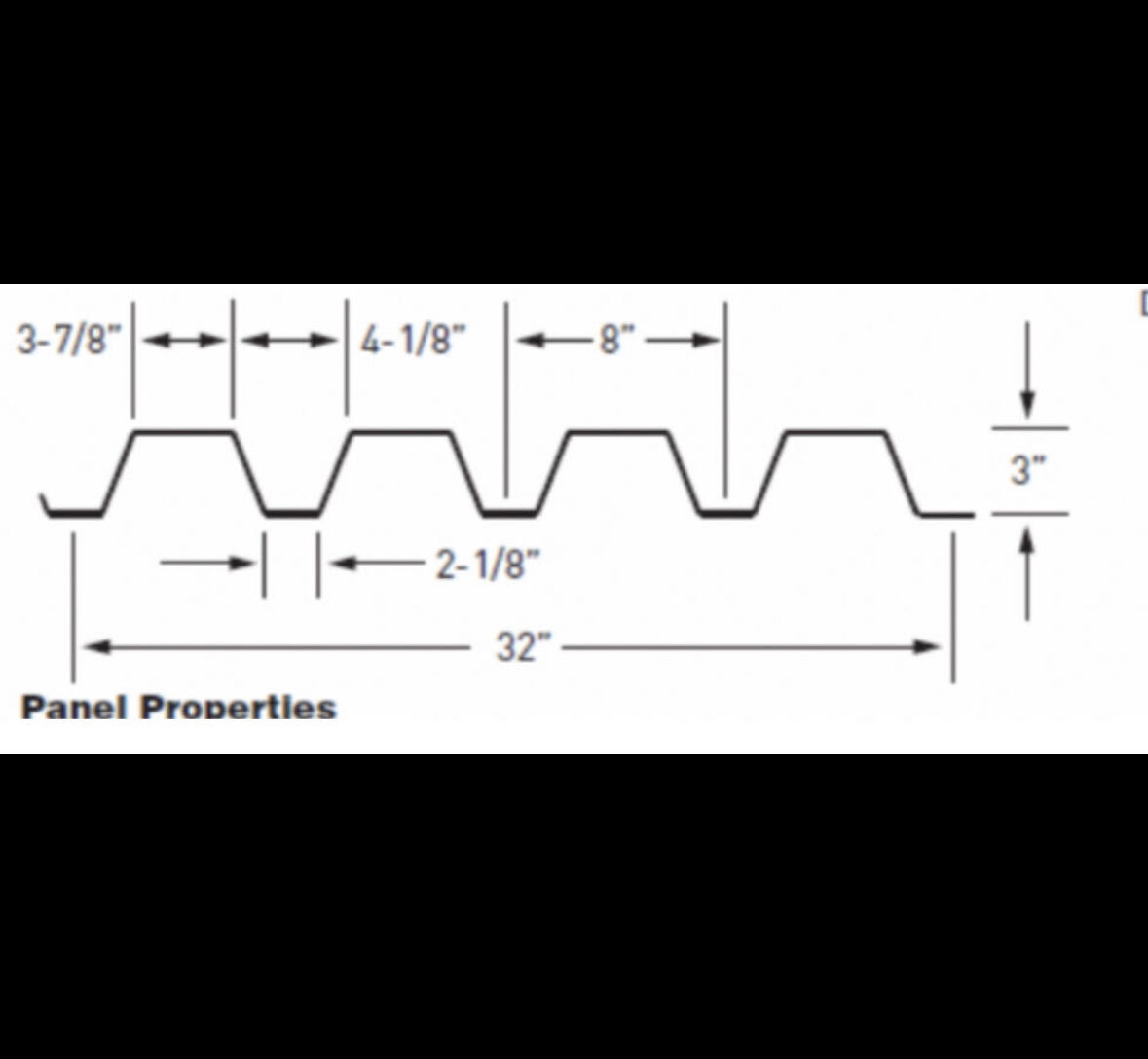

3" N Deck Profile

The term "3" N Deck Profile" typically refers to a specific type of steel decking used in construction for various applications such as roofing, flooring, and mezzanine systems. The "3"" in the name indicates the depth of the profile, which is 3 inches. N Deck is a common type of decking profile that is designed to provide structural support and serve as a base for roofing or flooring materials in commercial and industrial buildings.

Here are some key characteristics of a 3" N Deck Profile:

- Depth: The depth of the profile is 3 inches, which means it has a vertical distance of 3 inches from the top of the profile to the bottom.

- Ribbed Design: N Deck profiles typically have a ribbed or corrugated design with raised sections and recessed sections. This ribbed design adds stiffness and strength to the decking while also providing channels for the placement of concrete or other materials in some applications.

- Material: N Deck profiles are typically made from steel and may be coated with galvanized or other protective coatings to enhance durability and corrosion resistance.

- Width and Length: The width and length of N Deck panels can vary depending on the specific project requirements. Common widths include 24 inches, 30 inches, or other custom widths as needed. The length of the panels can also vary to fit the dimensions of the building.

- Attachment: N Deck panels are typically attached to the structural framing of a building using screws, fasteners, or other appropriate attachment methods.

- Applications: 3" N Deck profiles are commonly used in commercial and industrial construction for applications where structural support and a stable base are required. They can be used for roofing systems, composite floor systems, and mezzanine platforms.

- Load-Bearing Capacity: N Deck profiles are designed to provide high load-bearing capacity, making them suitable for applications where heavy loads need to be supported.

It's important to note that specific manufacturers may offer variations of N Deck profiles with different specifications, so the exact characteristics of a 3" N Deck Profile may vary depending on the manufacturer and the specific product line. When using N Deck profiles in construction projects, it's essential to follow the manufacturer's guidelines and engineering specifications to ensure the proper installation and performance of the decking system.