1" Metal Deck Roll Forming Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

1" Metal Deck Roll Forming Machine Specification

- Profile: 1" Deck

- Coil Width: 48"

- Forming Speed: 60ft Plus

- Material thickness: 18g - 22g

- Machine Weight: 20 ton

- Machine Footprint: 85ft

- Main power: 480v - 3ph - 60Hz

- Motor: 32hp

- Gearbox: Chain drive

- Stations: 28

- Cutting type: Pre Flying Shear

- Safety covers- optional

- E Stops

- FOB Orlando, Florida

1" Metal Deck Machine Description

A "Metal Deck Roll Forming Machine" is a specialized piece of equipment used in the construction and manufacturing industry. It is designed to fabricate metal deck panels, which are commonly used in the construction of buildings, bridges, and other structures as a formwork or support surface for concrete slabs. These metal deck panels are typically made of steel or other metals and are used to create a sturdy and reliable platform for pouring concrete.

The process of roll forming involves feeding a continuous strip of metal through a series of rollers and dies to gradually shape it into the desired profile. In the case of a metal deck roll forming machine, the machine is configured to produce metal deck panels with the specific dimensions and features required for a given construction project.

Some key features and functions of a typical metal deck roll forming machine may include:

- Material Feeding: The machine typically has a coil or sheet metal feeding system that continuously supplies the metal material to the forming process.

- Roll Forming Stations: These machines have multiple stations equipped with sets of rollers and dies that progressively shape the metal into the desired profile, including the shape and dimensions of the metal deck panel.

- Cutting and Shearing: Many metal deck roll forming machines are equipped with a cutting or shearing mechanism that can trim the formed metal panels to the required length.

- Control System: A control panel or computerized system allows operators to set parameters such as the dimensions of the metal deck panels and control the operation of the machine.

- Safety Features: Safety measures such as guards, emergency stop buttons, and safety interlocks are often incorporated to ensure safe operation.

The specific design and capabilities of a metal deck roll forming machine can vary depending on the manufacturer and the requirements of the end-users. These machines play a crucial role in the construction industry by efficiently producing metal deck panels, which are widely used for their structural and load-bearing capabilities in various building and infrastructure projects.

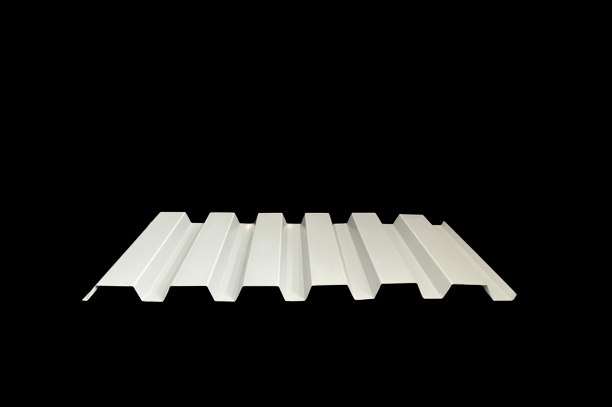

1" Metal Deck Profile

A "1" Metal Deck Profile" typically refers to a specific type of metal decking used in construction, particularly in the context of building roofs, floors, and mezzanines. This profile designation indicates the depth or thickness of the metal deck, with 1" indicating a depth of one inch. Metal decking is commonly made from steel and is used as a structural component in building construction.

A "1" Metal Deck Profile" typically refers to a specific type of metal decking used in construction, particularly in the context of building roofs, floors, and mezzanines. This profile designation indicates the depth or thickness of the metal deck, with "1"" indicating a depth of one inch. Metal decking is commonly made from steel and is used as a structural component in building construction.

- Depth: As mentioned, the "1" in the profile name signifies that the metal deck has a depth of one inch. This dimension is important as it determines the structural capacity and load-bearing capability of the deck.

- Ribbed Design: Metal deck profiles typically have a ribbed or corrugated design. These ribs provide strength and stiffness to the deck while also serving as a means for concrete to bond with the deck, creating a composite structural system.

- Load-Bearing Capacity: The depth and gauge (thickness) of the metal deck, along with the specific profile design, determine its load-bearing capacity. Deeper profiles generally have a higher load-bearing capacity and are used for applications where heavier loads are expected.

- Application: Metal deck profiles are commonly used in the construction of composite floor and roof systems. They provide support for poured concrete, creating a stable and strong structural platform. This is especially important in multi-story buildings.

- Attachment Methods: Metal deck panels are typically attached to the structural steel framing of a building using various methods, including welding, mechanical fasteners, or deck pins.

- Fire Resistance: Metal deck profiles can be designed to meet specific fire resistance requirements. They can be used in fire-rated floor and roof assemblies when combined with appropriate fireproofing materials.

- Finishes and Coatings: Metal decks may be galvanized or coated with protective finishes to enhance their durability and resistance to corrosion.

The specific design and characteristics of a "1" metal deck profile may vary depending on the manufacturer and the requirements of the construction project. Engineers and architects select the appropriate metal deck profile based on factors such as building design, anticipated loads, fire resistance requirements, and local building codes.

Overall, metal deck profiles play a vital role in modern construction, offering strength, stability, and versatility in a wide range of building applications.