1 1/2" Metal BDeck Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

1.5" B Deck Roll Forming Machine Specifications

- Profile: 1 1/2" B Deck

- Coil Width: 48"

- Forming Speed: 60ft Plus

- Material thickness: 18g - 24g

- Machine Weight: 20 ton

- Machine Footprint: 85ft

- Main power: 480v - 3ph - 60Hz

- Motor: 32hp

- Gearbox: Chain drive

- Stations: 28

- Cutting type: Hydraulic Shear

- Safety covers: optional

- E Stops

- FOB Orlando Florida

Metal 1.5" B Deck Machine Description

A 1.5-inch B-Deck roll forming machine is a piece of equipment designed to produce metal roof deck panels known as "B-Deck." B-Deck is a type of corrugated metal deck commonly used in construction for structural support and as a base for roofing systems. The "1.5-inch" specification likely refers to the depth of the corrugations in the deck panels.

Here are some key features and details you might expect from a 1.5-inch B-Deck roll forming machine:

- Material Compatibility: The machine is designed to work with specific types of metal coils, such as galvanized steel, stainless steel, or aluminum, depending on the project requirements.

- Roll Forming Process: Roll forming is the primary process used by these machines. It involves passing a flat metal strip through a series of rolls to gradually shape it into the desired corrugated profile.

- Cutting Mechanism: The machine uses a Hydraulic Shear cutting mechanism to cut the formed metal deck panels to the required length

- Control System: All roll forming machines come with computerized control systems for precise control over the forming process. This allows for customization and accuracy in producing deck panels of consistent quality.

- Speed and Production Capacity: The production speed and capacity of the machine depend on various factors, including the material thickness, and the specific design of the machine.

- Tooling: Roll forming machines use sets of rollers or tooling to shape the metal. The machine can come with interchangeable tooling to accommodate different profiles

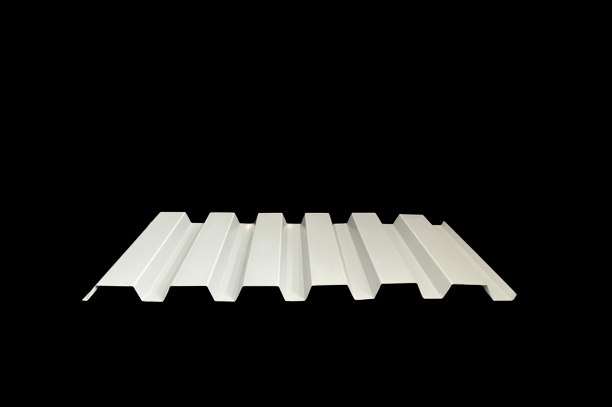

1.5" B Deck Profile

The term "1 and half inch B DECK profile" refers to a specific type of metal decking used in construction, particularly in building roofs and floors. B-Deck, also known as B-Decking or B-Deck Profile, is a common type of corrugated metal decking that is often used in commercial and industrial construction.

The "1 and half inch" measurement refers to the depth or height of the B-Deck profile. In this case, it is the depth of the corrugations or ribs in the decking is 1.5 inches.

B Deck Panels Applications

- Roof Decking: B-Deck panels are often used as a base for roofing systems. They provide a stable and durable surface for attaching roofing materials such as membrane roofing or shingles.

- Floor Decking: In addition to roofing, B-Deck panels can be used for floor decking in multi-story buildings. They serve as a structural component and a surface for pouring concrete slabs, creating composite floor systems.

- Mezzanines: B-Deck panels are also employed in the construction of mezzanines and elevated platforms within industrial and commercial buildings.

- Strength and Load-Bearing Capacity: The design of B-Deck panels, with their corrugations, provides them with excellent load-bearing capacity. This makes them suitable for supporting heavy loads in both roofing and flooring applications.

It's worth noting that while 1.5" B-Deck panels are a common size, there are variations in terms of rib spacing, material thickness, and other specifications. These variations allow builders and engineers to select the appropriate B-Deck panel for a particular construction project based on its structural requirements and load-bearing capacity.