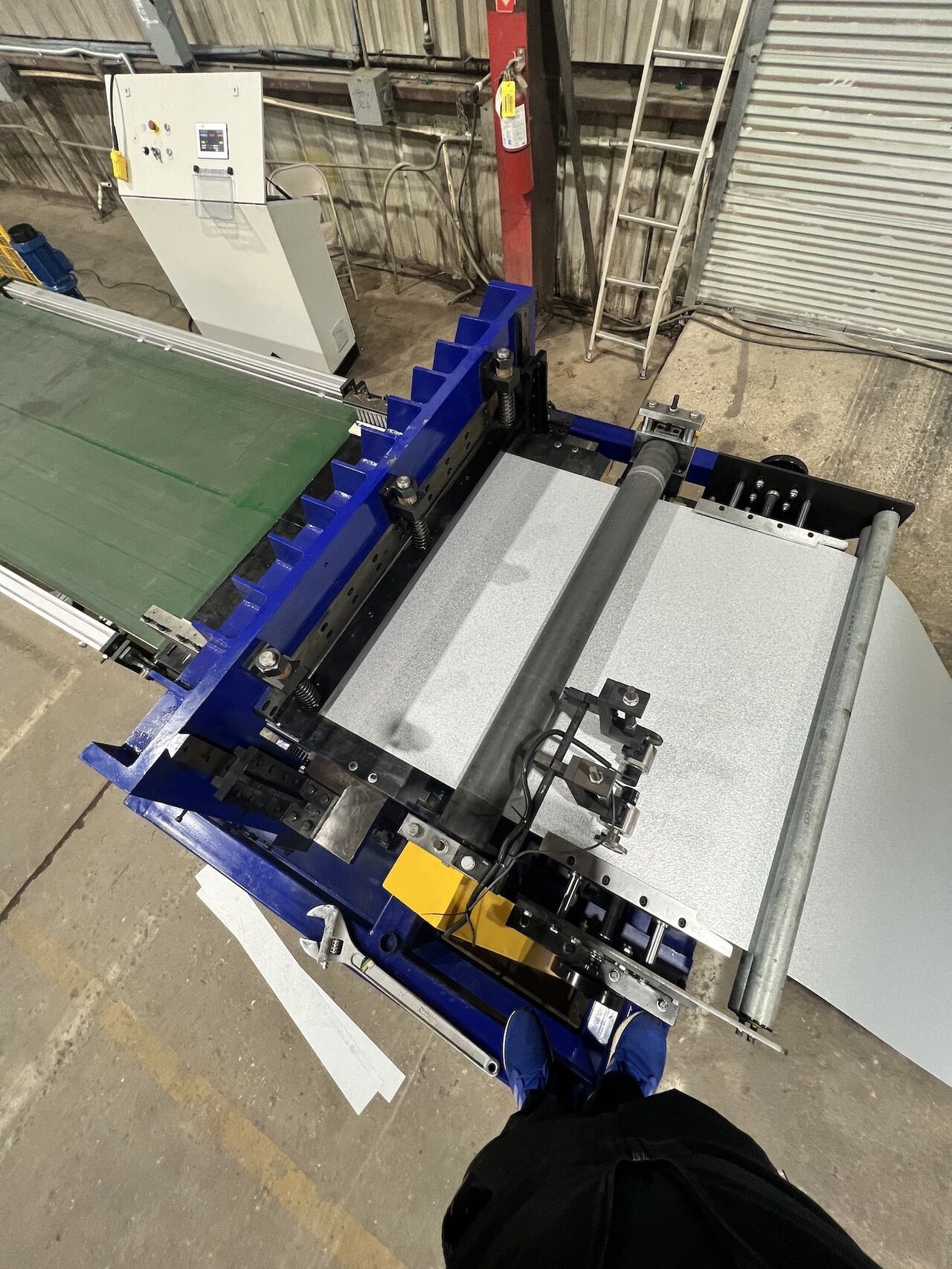

PBR Roof Panel Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

PBR Roof Panel Roll Forming Machine Specifications

- 40 feet long 5 feet wide

- Computer batching

- 20 stand

- Heavy Duty rollers

- Heavy Duty motor

- chain drive

- E stops and safety covers

- Read out in inches

- pre shear

PBR Roof Panel Roll Forming Machine Description

A PBR (Purlin Bearing Rib) roof panel roll forming machine is a piece of industrial equipment used in the construction and manufacturing industry. It is designed to automate the process of forming PBR roof panels, which are commonly used in the construction of metal roofs for various buildings, including warehouses, industrial facilities, agricultural structures, and more.

Here's an overview of how a PBR roof panel roll forming machine works:

- Material Feeding: The machine typically starts with a coil of metal sheet material, often galvanized steel or aluminum. This coil is loaded onto the machine.

- Uncoiling: The machine uncoils the metal coil, allowing it to feed continuously into the roll forming process.

- Roll Forming: The core function of the machine is roll forming. The metal sheet passes through a series of rollers that gradually shape it into the desired PBR profile. These rollers are custom-designed to produce the specific ribbed pattern characteristic of PBR roof panels. The process involves a series of steps, including pre-cutting, punching holes if necessary, and forming the ribs.

- Cutting: After the roll forming process, the continuous metal sheet is cut into individual PBR roof panel lengths. This can be done using various cutting mechanisms, such as hydraulic shears or flying cutoffs, depending on the machine's design.

- Stacking or Packaging: Once the panels are cut to the desired length, they are either stacked or packaged for transportation and further processing.

- Control System: A control system manages the entire operation, ensuring precise measurements, cutting, and forming according to the specified parameters. Operators can input the desired dimensions and settings into the control panel.

PBR roof panels are known for their high structural integrity due to their ribbed design, making them suitable for withstanding heavy loads and adverse weather conditions. They are also efficient to produce in large quantities using a roll forming machine.

It's worth noting that there are different variations of PBR roof panel roll forming machines available, with varying levels of automation and production capacities. The specific features and capabilities of a machine may vary based on the manufacturer and model. These machines are commonly used in metal roofing and siding manufacturing plants, and they play a crucial role in the construction industry by producing durable and cost-effective roofing solutions.

PBR Roof Panel Profile

A PBR (Purlin Bearing Rib) roof panel profile refers to the specific design and characteristics of a type of metal roofing panel commonly used in the construction industry. PBR roof panels are known for their durability, strength, and ability to provide effective weather protection for various types of buildings. Here are some key features and characteristics of a typical PBR roof panel profile:

- Ribbed Design: The most distinctive feature of a PBR roof panel is its ribbed or corrugated design. These ribs run along the length of the panel and provide additional structural strength, which makes PBR panels suitable for spanning long distances without the need for excessive support. The ribs also help to channel water away from the roof's surface.

- High Ribs: PBR roof panels have relatively high ribs compared to some other roofing profiles, which further enhances their strength and load-bearing capacity. The height of the ribs can vary, but it's typically around 1.25 inches (31.75 mm) or more.

- Deep Channels: PBR panels also have deep channels or valleys between the ribs. These channels help to direct water away from the roof's surface, reducing the risk of leaks and water damage.

- Concealed Fasteners: Many PBR roof panels are designed with concealed fasteners. This means that the fasteners (screws or clips) used to attach the panels to the underlying structure are hidden beneath the overlapping sections of the panels. This not only provides a clean and streamlined appearance but also helps to prevent potential leaks at the fastening points.

- Available Materials: PBR roof panels are typically made from galvanized steel, aluminum, or other metal materials that are resistant to corrosion and can withstand exposure to the elements.

- Versatility: PBR roof panels are versatile and can be used in a wide range of applications, including industrial and commercial buildings, agricultural structures, residential homes, and more.

- Longevity: Due to their durable construction and resistance to weathering, PBR roof panels are known for their long service life, which can be several decades with proper maintenance.

- Customization: PBR roof panels can be customized to meet specific design and color preferences. They are often available in a variety of colors and finishes to match the aesthetic requirements of different projects.

PBR roof panels are popular in regions with harsh weather conditions, as they provide excellent protection against rain, snow, wind, and other environmental factors. Their strength and longevity make them a preferred choice for many construction projects where a reliable and durable roofing solution is needed

All roll forming machinery is fully assembled at our factory in Orlando Florida. Our Roll Forming Machines come with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

Please note: Roll Forming Machines LLC does not provide in-house financing, but the leasing companies listed here can assist with financing our equipment. Roll Forming Machines LLC is not affiliated with any of these companies.

To request a quote or If you have any questions about our machines, please fill out the contact form below.