Pbr 20 Station Electric Shear Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

20 Station PBR Roll Forming Machine Specifications

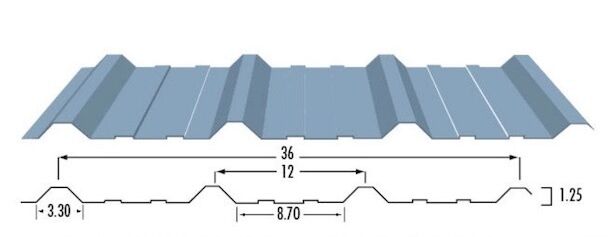

Pbr Roof Panel Roll Forming Machine produce a 36" profile you can form perfect panels to any length without time and material waste

cutting type Electric Shear

20 Stations

Pbr forms 70 to 80 feet per minute

Heavy Duty Construction

Forms 24g to 29g

Coil width 43" wide

Chain Drive

Computer Controls with 10 batching groups

E stops

FOB Orlando Florida

A 20-station PBR (Purlin Bearing Rib) roll forming machine is a type of industrial equipment used in the metalworking industry to produce PBR roof and wall panels. PBR panels are commonly used in construction for roofing and cladding applications. The "20-station" part of the machine's description indicates that it has 20 sets of rollers or forming stations that progressively shape a flat sheet of metal into the desired PBR profile.

Here's a basic overview of how a PBR roll forming machine works and its components:

- Decoiler: The process typically starts with a decoiler, which unwinds a coil of metal sheet, usually made of steel or aluminum, that will be used to create the PBR panels.

- Guiding and Feeding: The metal sheet is then guided and fed into the first station of the roll forming machine.

- Roll Forming Stations: The heart of the machine is its roll forming stations. Each station consists of a set of rollers, which gradually bend the metal sheet into the PBR profile. In the case of a 20-station machine, this process is broken down into 20 distinct steps, with each station performing a specific forming operation.

- Cutting: After the metal has been fully formed into the desired PBR profile, a cutting mechanism, often a flying shear or a hydraulic shear, is used to cut the panel to the desired length.

- Stacker or Collector: The finished PBR panels are then stacked or collected for further processing or shipping.

PBR panels typically have a distinctive shape characterized by a raised rib in the middle and two smaller ribs on each side. This design provides strength and durability, making them suitable for roofing and wall applications, particularly in industrial and commercial buildings.

The specific design and features of a 20-station PBR roll forming machine may vary depending on the manufacturer and the requirements of the production process. Such machines can be highly automated and can produce PBR panels with consistent quality and high efficiency. They are a key part of modern metalworking facilities that specialize in producing roofing and cladding materials.