Patio W Rollformer

Get a Quote

Send us a message and we’ll get back to you shortly.

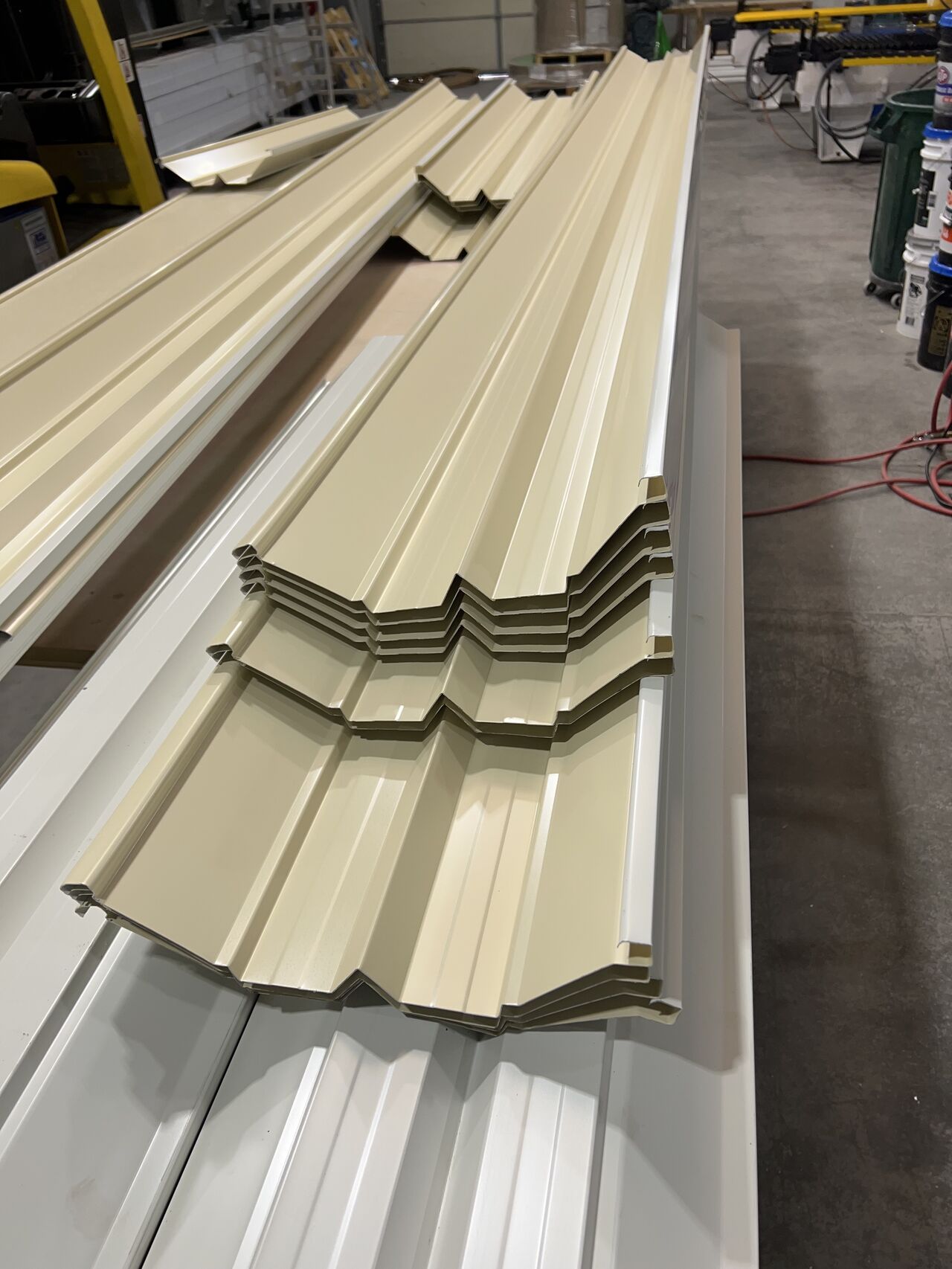

Patio W Profile Roll Forming Machine Specifications

- Profile: Patio cover pan

- Coil Width: 19" +/-

- Forming Speed: 70ft +

- Material thickness: 0.27 - 0.32

- Machine Weight: 5 ton

- Machine Footprint: 32ft

- Main power: 240v - 3ph - 60Hz

- Motor: 8 Hp

- Gearbox: Chain drive

- Stations: 22

- Cutting type: Hydraulic / Electric

- Control system: Delta

- Safety covers

- E Stops

- FOB Orlando, Florida

Patio W Profile Roll Forming Machine Description

A Patio W Profile Roll Forming Machine is a piece of equipment used in the manufacturing and construction industry to produce patio W-profile metal panels or components. These machines are commonly used to create customized metal profiles for outdoor patios, roofs, and similar structures. The "W" profile typically refers to a particular shape or design of the metal panel used in such applications.

Here's how a roll forming machine like this typically works:

- Material Feeding: The raw material, usually in the form of a metal coil or sheet, is fed into the roll forming machine.

- Roll Forming Process: The machine consists of a series of rollers or roll tooling that progressively shape the material into the desired W-profile. Each set of rollers performs a specific bending or forming operation on the material as it passes through.

- Cutting: In some roll forming machines, there may be a cutting station where the continuous metal strip is cut into the desired lengths or panels.

- Output: The finished patio W-profile panels or components are then collected or stacked for further processing or installation.

These machines are highly specialized and can be customized to produce specific profiles and dimensions required for a particular project. They are commonly used in the construction of outdoor structures like patios, awnings, canopies, and roofing systems, where durable and weather-resistant materials are needed.

The choice of materials (e.g., steel, aluminum, or other metals) and the specific profile design can vary depending on the project's requirements and environmental factors. Patio W Profile Roll Forming Machines are just one type of roll forming equipment used in the metalworking industry, and they play a crucial role in producing high-quality, customized metal components for various applications.

All roll forming machinery is fully assembled at our factory in Orlando Florida. Our Roll Forming Machines come with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

To request a quote or If you have any questions about our machines, please fill out the contact form below.