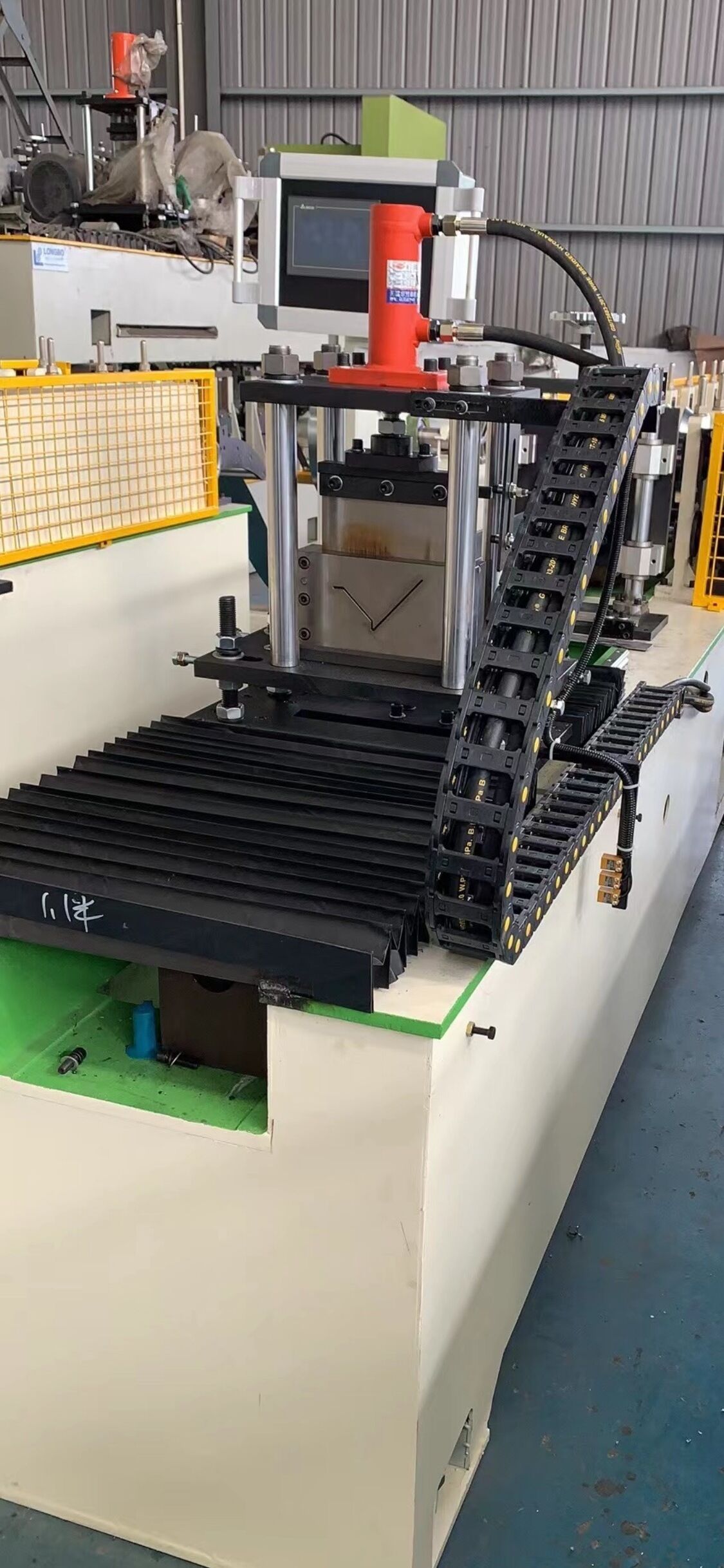

New FHA Drip Edge Roll Forming Machine

To request a quote or if you have any questions about our machines, please fill out the online contact form below or download the quote form and send to [email protected].

RFM ENQUIRY FORM .pdf file

Please be as detailed as possible in your message including technical information, profile needed, gauge of material, power supply requirements, shipping location etc.

FHA Drip Edge Roll Forming Machine Specifications

- FHA Drip Edge

- Drip Edge with flying shear

- 2-1/2" face and 3" face

- Horizontal is adjustable max 4"

Drip Edge Roll Forming Machine Description

A drip edge roll forming machine is a specialized piece of equipment used in the construction and roofing industry to manufacture drip edge profiles. Drip edge is a vital component in roofing systems, as it helps to direct water away from the edges of the roof, preventing water from seeping under the roofing materials and causing damage to the underlying structure. Drip edge also provides a neat, finished look to the roof's edge.

Here's how a drip edge roll forming machine works:

- Material Feeding: The machine typically starts with a coil of metal material, such as galvanized steel or aluminum, which is loaded onto the machine. The material is usually in the form of a long strip or coil.

- Roll Forming: The machine uses a series of rollers and dies to gradually shape and bend the metal strip into the desired drip edge profile. The rollers and dies are designed to create the specific dimensions and features of the drip edge, including any bends, angles, and flanges.

- Cutting: As the metal strip is continuously fed through the roll forming process, it is cut to the desired length using cutting blades or shears. This ensures that the drip edge pieces are produced in the required lengths.

- Forming Variations: Some drip edge profiles may have variations, such as different angles or shapes on one or both sides. The roll forming machine can be customized to produce different profiles as needed.

- Collecting the Finished Product: The finished drip edge pieces are then collected, typically in bundles or on a conveyor, ready for packaging and distribution.

Drip edge roll forming machines are efficient and precise, allowing for the mass production of drip edge components with consistent quality. They are commonly used by roofing contractors and manufacturers to produce drip edge products in various lengths, widths, and profiles to meet the specific requirements of roofing projects.

It's important to note that the exact specifications and features of a drip edge roll forming machine can vary depending on the manufacturer and the specific needs of the user. Additionally, safety precautions should be followed when operating these machines, as they often involve the use of heavy materials and moving parts.

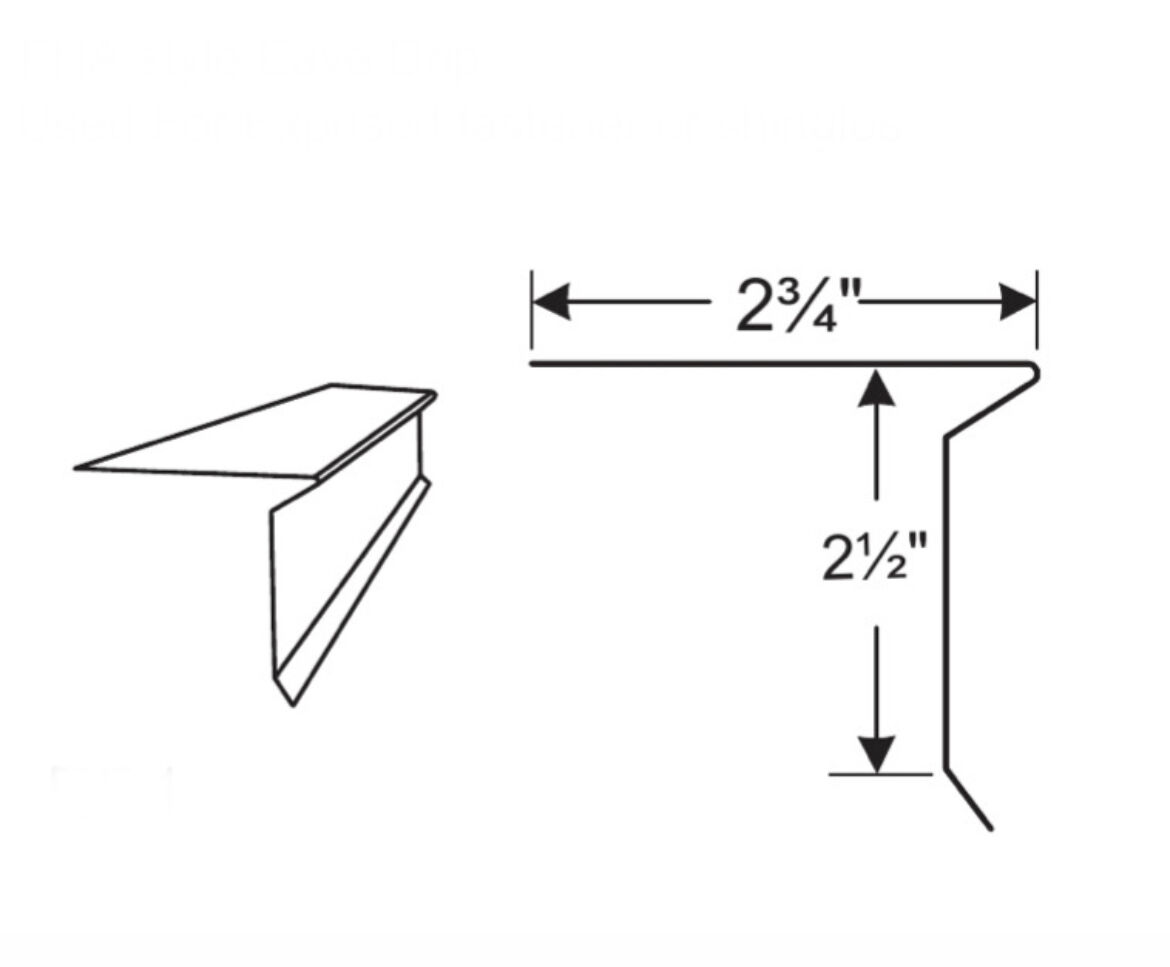

FHA Drip Edge Profile

The term "FHA Drip Edge Profile" refers to a specific type of drip edge profile that meets the requirements set forth by the Federal Housing Administration (FHA) in the United States. The FHA is a government agency that provides mortgage insurance on loans made by FHA-approved lenders. When it comes to roofing and construction standards, including drip edge profiles, the FHA may have certain guidelines to ensure the safety and durability of residential properties financed through FHA-insured loans.

While the specific details of an FHA Drip Edge Profile may vary over time or regionally, it generally means that the drip edge installed on a property meets the standards and specifications set by the FHA. These standards may cover aspects such as:

- Material: The FHA may specify the type of material that should be used for the drip edge, such as galvanized steel or aluminum, to ensure durability and longevity.

- Dimensions: There may be requirements regarding the width, length, and overall dimensions of the drip edge to ensure it effectively directs water away from the roof's edge.

- Attachment: The FHA may provide guidelines on how the drip edge should be attached to the roof, such as using roofing nails or screws, and the spacing between attachment points.

- Overhang: The amount of overhang that the drip edge should provide beyond the edge of the roof may also be specified to prevent water from flowing back under the roofing materials.

- Surface Finish: Guidelines may cover the surface finish of the drip edge material, such as paint or coating, to protect it from corrosion and ensure a neat appearance.

It's essential for contractors and builders to be aware of and adhere to FHA guidelines when installing drip edge profiles or other roofing components on properties that will be financed with FHA-insured loans. Non-compliance with FHA standards could affect the property's eligibility for FHA financing.

However, the specific requirements for an FHA Drip Edge Profile may change over time, so it's advisable to consult the most recent FHA guidelines or regulations or contact an FHA-approved lender or inspector for up-to-date information on FHA requirements for drip edge installation in your area.