New B Deck Roll Forming Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

B Deck Roll Forming Machine Specifications

The b deck foot print is 60ft long and 6ft wide plus uncoiler the overal space required is 75ft

Hydraulic pre shear and flying shear speed 80ft a minute

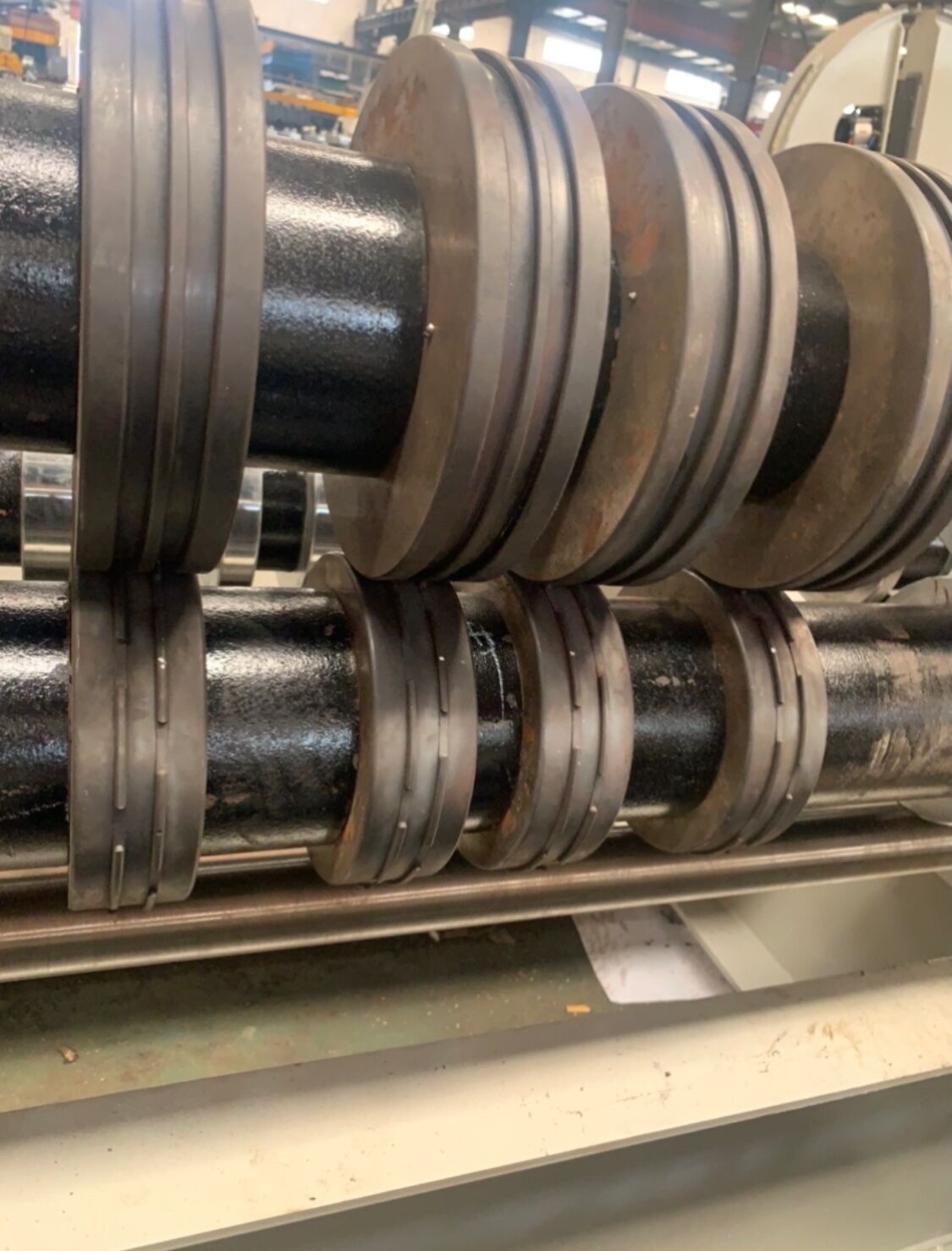

With embossing and perforation stations Main shaft 4" Embosser shaft 5" Perforation shaft 5"

- Profile: 1 1/2" B Deck

- Coil Width: 48"

- Forming Speed: 60ft Plus

- Material thickness: 18g - 24g

- Machine Weight: 20 ton

- Machine Footprint: 85ft

- Main power: 480v - 3ph - 60Hz

- Motor: 32hp

- Gearbox: Chain drive

- Stations: 28

- Cutting type: Hydraulic Shear

- Safety covers- optional

- E Stops

- FOB Orlando, Florida

B Deck Roll Forming Machine Description

A B Deck Roll Forming Machine is a piece of equipment used in the manufacturing and construction industry to produce B Deck profiles. B Deck is a type of corrugated metal decking that is commonly used as a structural component in roofing and flooring systems. It provides support and stability to buildings and is often used in commercial and industrial construction projects.

The roll forming process involves feeding a coil of metal sheet through a series of rollers that gradually shape the metal into the desired profile. In the case of a B Deck Roll Forming Machine, the rollers are designed to create the characteristic corrugations or waves that are typical of B Deck.

Here are some key features and functions of a B Deck Roll Forming Machine:

- Material Feeding: The machine typically starts with a coil of flat metal sheet, usually steel or aluminum. This coil is loaded onto the machine, and the material is fed into the roll forming section.

- Roll Forming: The metal sheet passes through a series of rollers, each with a specific contour. These rollers gradually bend and shape the metal into the B Deck profile, creating the corrugations and other features of the decking.

- Cutting: Once the desired length of B Deck has been formed, the machine may have a cutting mechanism to trim the sheet to the required size. This ensures that the produced deck panels are of uniform length.

- Stacking and Output: After cutting, the formed B Deck panels are typically stacked or collected for further processing or transportation to construction sites.

B Deck Roll Forming Machines are designed to be efficient and precise, allowing manufacturers to produce B Deck panels in large quantities with consistent quality. These panels are then used in various construction applications, such as roofing, flooring, and mezzanine systems, to provide structural support and stability.

It's important to note that there may be variations in the design and features of B Deck Roll Forming Machines depending on the manufacturer and specific requirements of the production process.