New 2" x 2" Tube Roll former

Get a Quote

Send us a message and we’ll get back to you shortly.

2" x 2" Metal Tube Roll Forming Machine Specifications

New 2" x 2" Roll forming machine manufactured, and installed for shade, patio cover and pergola manufacture based in the USA.

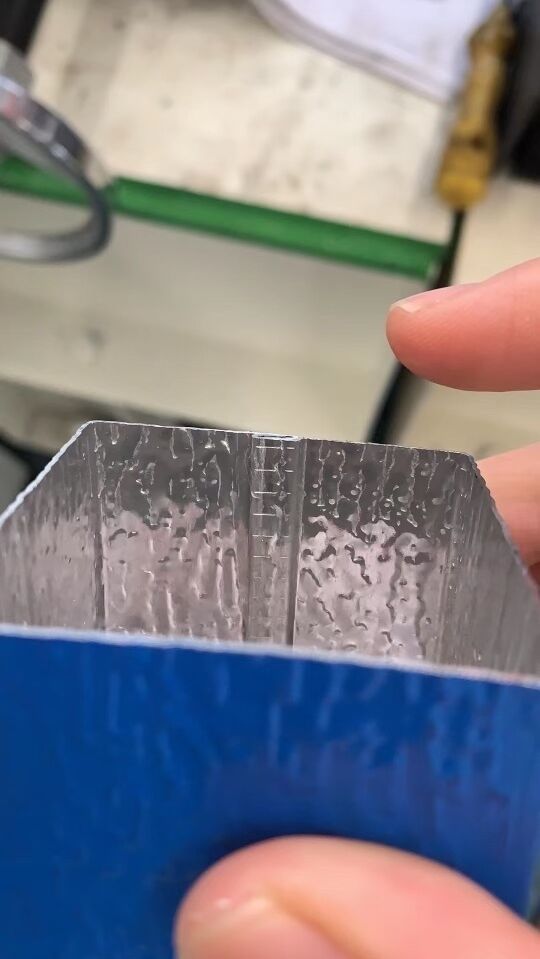

- Profile - 2" x 2" Tube

- Coil Width - 9.5"

- Forming Speed - 70 - 80

- Material thickness - 0.27

- Machine Weight - 6 Ton

- Machine Footprint - 33ft x 4 ft

- Main power - 240v - 3ph - 60Hz

- Motor - 8 Hp

- Gearbox - Chain Drive

- Stations - 22

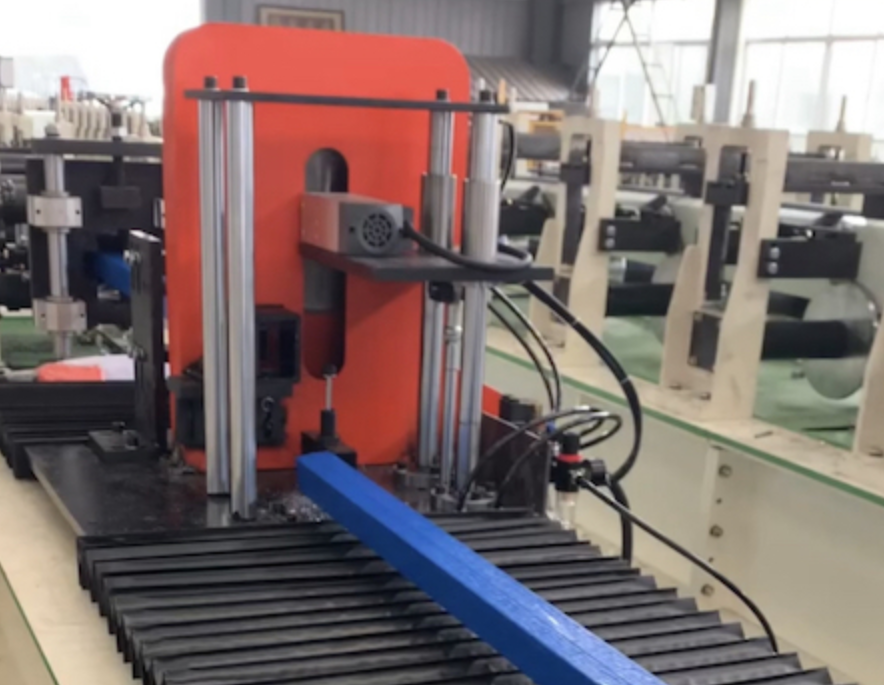

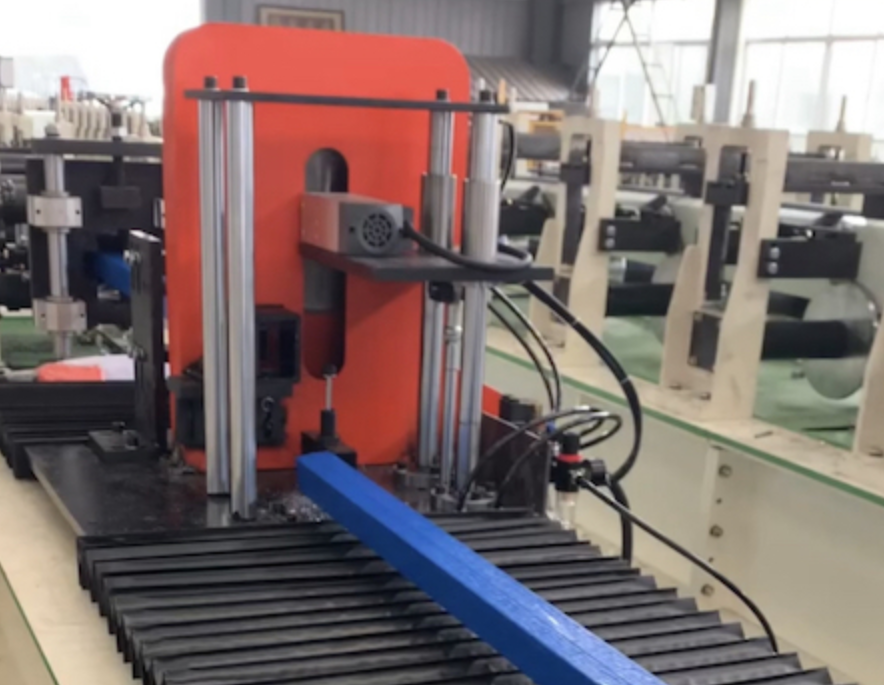

- Cutting type - Flying saw

- Control system - Delta

- Safety covers- optional

- E Stops

- FOB Orlando, Florida

2" x 2" Metal Tube Machine Description

A 2" x 2" metal tube roll forming machine is a piece of industrial equipment used in manufacturing to shape metal strips or coils into square tubes with dimensions of 2 inches by 2 inches. Roll forming is a metal fabrication process that involves passing a continuous strip of metal through a series of rollers, each of which gradually shapes the metal into the desired profile.

Here are some key components and features you might find in a typical 2" x 2" metal tube roll forming machine:

- Entry Guide: The machine may have an entry guide that helps guide the metal strip into the roll forming process.

- Rollers: The heart of the roll forming machine is a series of rollers. These rollers are designed with specific contours and gradually shape the metal strip into a square tube as it passes through them. There are typically multiple sets of rollers arranged in a sequence to achieve the final shape.

- Drive System: Rollers are powered by a drive system, which ensures the consistent and precise movement of the metal strip through the machine.

- Cut-off System: At the end of the roll forming process, a cut-off system may be used to trim the formed tube to the desired length. This can include mechanisms such as saws or shears.

- Control Panel: Modern roll forming machines are often equipped with a control panel that allows operators to set parameters such as roll spacing, speed, and length of cut.

- Material Handling: The machine may also include material handling equipment, such as decoilers or coil holders, to feed the metal strip into the roll forming process.

- Safety Features: Roll forming machines typically have safety features such as emergency stop buttons and guards to ensure the safety of operators.

- Tooling: Depending on the specific design and size of the square tube being produced, the machine may require different sets of tooling or rolls to achieve the desired dimensions and shape.

It's important to note that the exact specifications and features of a 2" x 2" metal tube roll forming machine can vary depending on the manufacturer and the specific requirements of the production process. These machines are commonly used in industries such as construction, automotive, and manufacturing, where square or rectangular tubes are needed for various applications.

All roll forming machinery is fully assembled at our factory in Orlando Florida. and comes with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

To request a quote or If you have any questions about our machines, please fill out the contact form below.