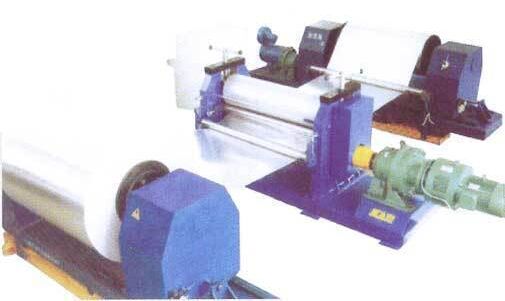

Metal Embossing Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

A metal embossing machine is a piece of equipment used in various industries to create raised or recessed designs, patterns, or text on metal surfaces. The process of metal embossing involves using pressure to deform the metal sheet or plate, creating a three-dimensional relief on the surface. This embossed metal can be used for decorative purposes, branding, labeling, or functional applications.

Here are some key features and aspects of metal embossing machines:

- Embossing Process: Metal embossing machines typically work by pressing a pattern or die into a metal sheet or plate. This can be done through hydraulic, mechanical, or pneumatic force, depending on the type of machine.

- Materials: These machines can be used with various types of metals, including aluminum, brass, copper, stainless steel, and more. The choice of metal depends on the specific application and desired appearance.

- Patterns and Designs: Metal embossing machines can create a wide range of patterns, designs, and textures on the metal surface. These patterns can be customized to meet the requirements of the project, whether it's for decorative purposes or functional needs like grip-enhancing textures.

- Applications: Metal embossing is used in many industries, including automotive, aerospace, signage, jewelry making, architectural design, and more. It is often employed for creating logos, serial numbers, decorative patterns, and text on metal components.

- Machine Types: There are different types of metal embossing machines, including manual, semi-automatic, and fully automatic machines. Manual machines require operators to load and unload the metal sheets, while automated machines can handle larger volumes with minimal human intervention.

- Die Sets: Metal embossing machines use die sets or molds with the desired patterns or text. These can be customized to match the specific design requirements. Die sets can be made from various materials, including hardened steel, to withstand the pressure and provide precise results.

- Thickness and Size: Metal embossing machines can accommodate various sheet thicknesses and sizes. The machine's capabilities will depend on its specifications, so it's important to choose the right machine for the intended application.

- Quality Control: Quality control is crucial in metal embossing to ensure consistent results. Operators need to monitor factors such as pressure, alignment, and material properties to achieve the desired embossed finish.

Metal embossing machines are valuable tools for adding aesthetic and functional elements to metal products. They are used in manufacturing processes where customized, textured, or branded metal surfaces are required. When choosing a metal embossing machine, consider the type of metal, pattern complexity, production volume, and other specific requirements of your project.