Double layer roll forming machine

Get a Quote

Send us a message and we’ll get back to you shortly.

- Profiles: PBR - AG

- Stands: 16

- Speed: 0 - 12m / min

- Cutting: Hydraulic post cutting

- Coil thickness: 0.4 / 0.8

- Main Power: 7.5

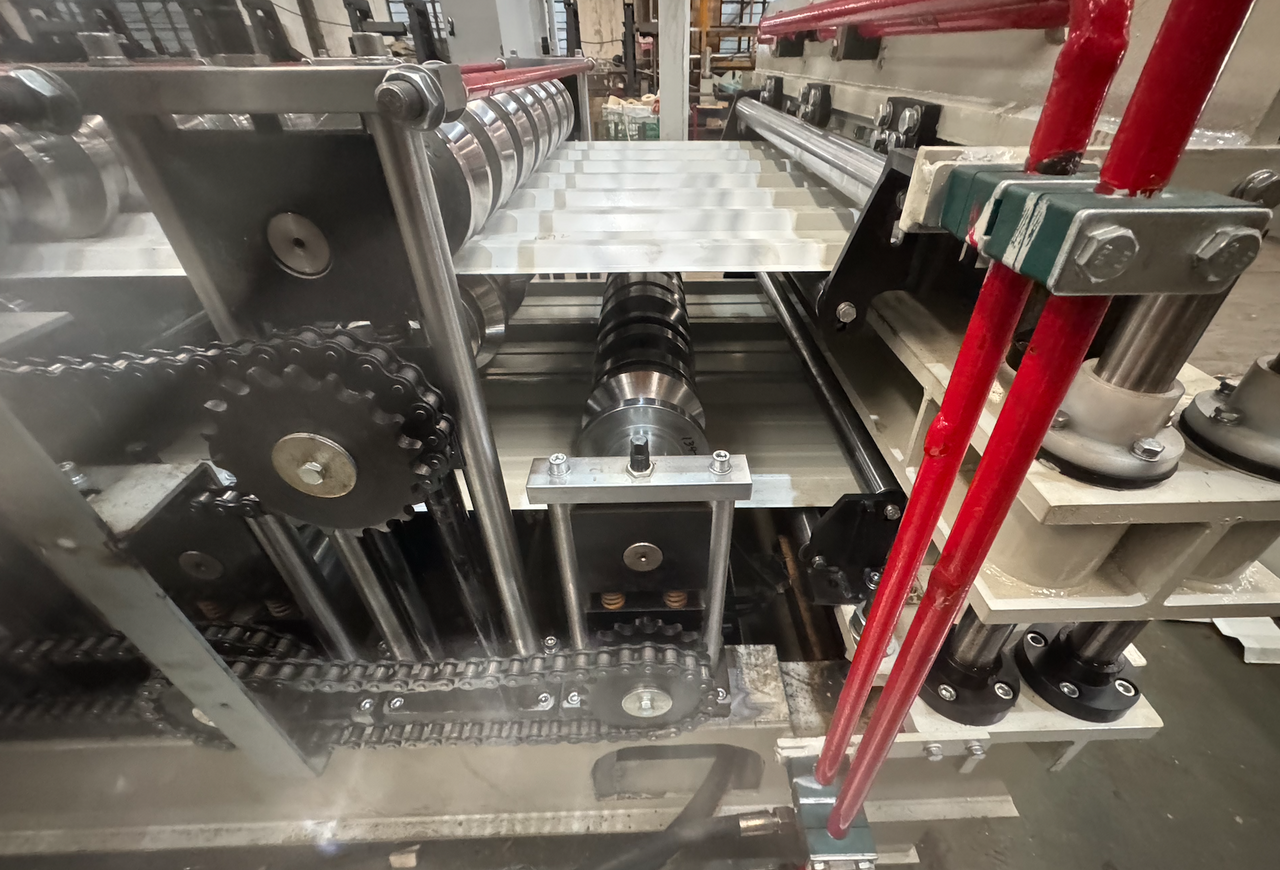

- Drive: Chain drive

- Control system: PLC

Double Layer Forming Machine Description

A Double Layer Forming Machine is a type of industrial equipment used in various manufacturing processes, particularly in the metalworking and sheet metal industry. This machine is designed to bend and shape metal sheets or other materials into two distinct layers or profiles, typically with different shapes or dimensions. It is often used in the production of roofing sheets, wall cladding panels, and other similar products where a double-layered structure is required for added strength, insulation, or aesthetic purposes.

Key features and functions of a Double Layer Forming Machine may include:

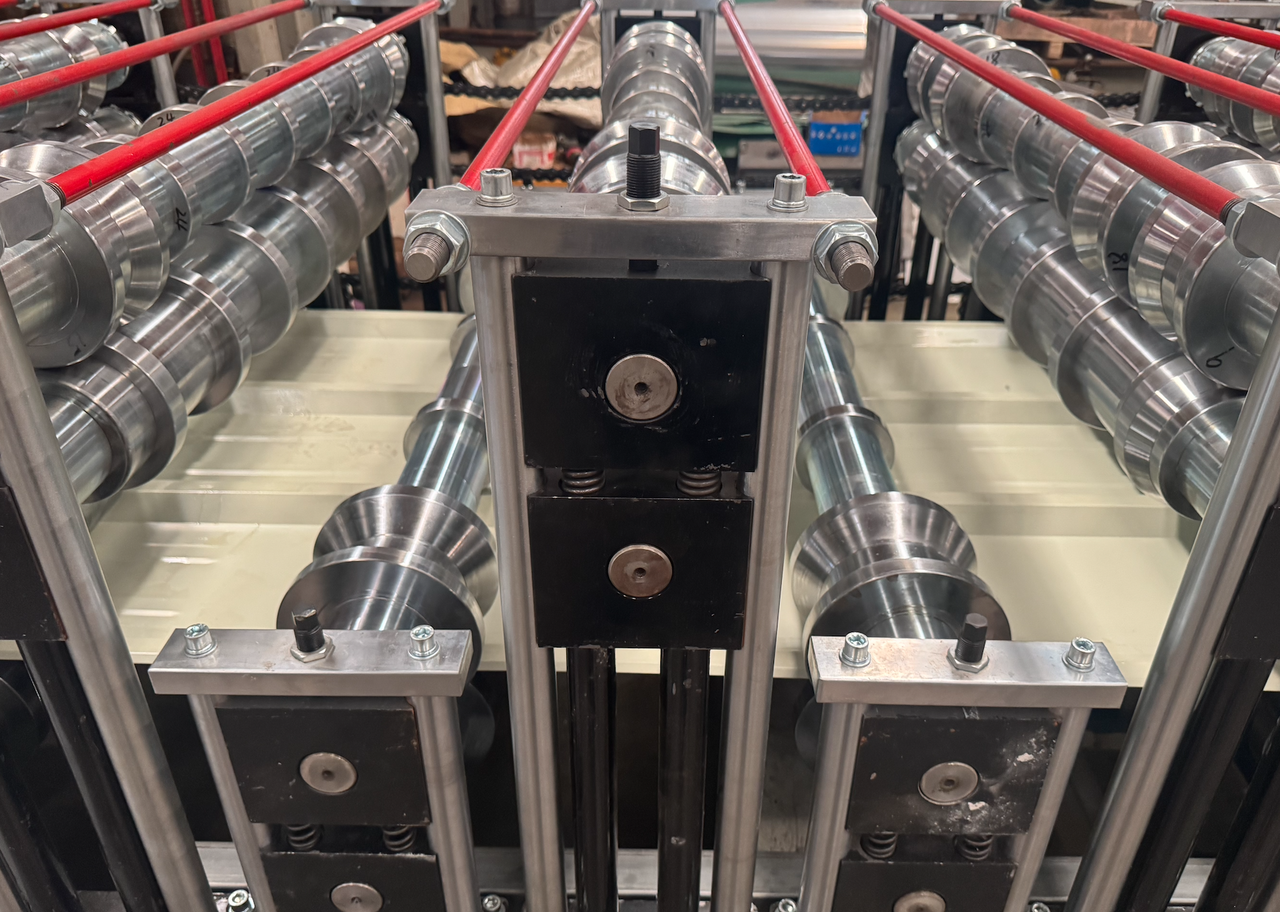

- Two Sets of Rollers: These machines are equipped with two sets of rollers, each responsible for forming one layer of the material. The rollers can be adjusted to the desired shape and size.

- Material Feeding System: Double Layer Forming Machines typically have a material feeding system that allows for the smooth and continuous feeding of the metal sheets or coils.

- Adjustable Parameters: Operators can adjust various parameters such as the roll gap, speed of the rollers, and the angle of the bending or forming process to achieve the desired double-layered profile.

- Precision and Consistency: These machines are engineered for high precision and consistency in forming, ensuring that the resulting double-layered sheets or panels meet quality standards.

- Control Panel: A control panel allows operators to set and monitor the machine's parameters and operation, ensuring efficient and safe production.

- Safety Features: Safety mechanisms such as emergency stop buttons and protective guards are typically included to protect operators and prevent accidents.

The specific capabilities and features of a Double Layer Forming Machine can vary depending on the manufacturer and model. These machines are versatile and can be used for a wide range of applications, including the production of roofing sheets, wall panels, and other building components.

When using a Double Layer Forming Machine, it's important to follow safety guidelines and have operators with the necessary training and experience to ensure safe and efficient operation. Additionally, regular maintenance is essential to keep the machine in good working condition and prolong its lifespan.

Benefits of using a double layer roof panel roll forming machine

Using a Double Layer Roof Panel Roll Forming Machine offers several benefits in the construction and manufacturing industry, particularly for roofing and cladding applications. Here are some of the key advantages:

- Cost Efficiency: Double layer roof panel roll forming machines are highly efficient in producing roofing panels. They can work continuously, reducing labor costs, and can create panels quickly, saving both time and money.

- Customization: These machines can be adjusted to create various panel profiles and sizes. This versatility allows for customization to meet specific project requirements, accommodating different design preferences and building needs.

- High Precision: Modern roll forming machines are designed for high precision, ensuring that the panels they produce meet strict quality standards. This precision results in well-fitting and consistent panels, reducing the need for adjustments or rework.

- Material Savings: Roll forming minimizes material waste. The process shapes metal coils into panels with minimal scrap, making it a cost-effective and environmentally friendly option.

- Speed and Efficiency: Double layer roll forming machines can work at high speeds, producing large quantities of panels quickly. This efficiency is particularly advantageous for large-scale roofing projects.

- Reduced Labor Intensity: Automated roll forming machines reduce the need for extensive manual labor. This not only saves on labor costs but also improves workplace safety by minimizing the risks associated with manual handling of heavy materials.

- Consistency: These machines can produce panels with consistent dimensions and quality, ensuring that every panel matches the specified standards. This consistency is crucial for the structural integrity and aesthetics of the roof or cladding.

- Versatility: Double layer roll forming machines can handle a variety of materials, including different metals and alloys. This versatility allows for the production of panels suitable for various climates and conditions.

- Longevity and Durability: Panels produced by roll forming machines are known for their durability and longevity. They can withstand harsh weather conditions, providing long-lasting protection to buildings.

- Energy Efficiency: Many roll forming machines are designed to operate efficiently, consuming less energy per panel produced compared to other manufacturing methods.

- Reduced Installation Time: Precisely manufactured panels fit together seamlessly during installation, reducing installation time and labor costs. This efficiency can lead to shorter project timelines.

- High-Quality Finish: Roll-formed panels often have a smooth and aesthetically pleasing finish. They can be coated or painted to enhance their appearance and durability.

In summary, using a Double Layer Roof Panel Roll Forming Machine offers numerous benefits, including cost efficiency, customization options, high precision, material savings, speed, and consistency. These advantages make it a popular choice for manufacturing roofing and cladding panels in a wide range of construction projects.

PBR Roof Panel Description

PBR (Purlin Bearing Rib) roof panels are a type of metal roofing system commonly used in industrial, commercial, and agricultural buildings. They are popular for their durability, weather resistance, and ease of installation. Here is a description of PBR roof panels:

- Material: PBR roof panels are typically made from high-quality metal materials such as steel or aluminum. These materials offer excellent strength and resistance to corrosion, making them suitable for long-term use in various environments.

- Profile: The distinguishing feature of PBR roof panels is their unique profile. They have deep, high ribs with an exposed fastener design. These ribs provide added strength and stiffness to the panels, making them capable of spanning longer distances without the need for additional structural support.

- Rib Spacing: The rib spacing in PBR roof panels is typically 12 inches or 16 inches, although variations can occur. The wider rib spacing allows for quicker installation and is a defining characteristic of PBR panels.

- Fasteners: PBR roof panels use exposed fasteners, which means the fasteners (screws or bolts) are visible on the surface of the panels. This design simplifies installation but may require periodic maintenance to ensure the fasteners remain secure over time.

- Coatings: PBR roof panels are often coated with protective finishes, such as galvanized or galvalume coatings, to enhance their resistance to rust and corrosion. Additionally, they can be painted with various colors to match the aesthetics of the building.

- Length and Width: PBR roof panels come in standard lengths and widths, which can vary depending on the manufacturer and specific product. These panels are typically available in a range of lengths to accommodate different building dimensions.

- Installation: PBR roof panels are relatively easy to install, thanks to their exposed fastener system. They are typically attached to the underlying structure, such as purlins or trusses, using the exposed fasteners, ensuring a secure and weather-resistant connection.

- Weather Resistance: PBR roof panels are designed to withstand various weather conditions, including rain, snow, wind, and UV exposure. They are known for their durability and ability to provide effective protection against the elements.

- Applications: PBR roof panels are commonly used in the construction of warehouses, industrial facilities, agricultural buildings, and commercial structures. Their strength and affordability make them a popular choice for roofing projects where a robust and cost-effective solution is needed.

- Insulation: PBR roof panels can be used with insulation materials to improve energy efficiency and thermal comfort within a building. Insulation is often installed between the roof panels and the building's interior to regulate temperature and reduce energy costs.

PBR roof panels are a versatile roofing solution known for their structural integrity, ease of installation, and long-lasting performance. They offer an economical and reliable choice for a wide range of building applications.

AG Roof Panel Description

"AG Roof Panel" does not refer to a widely recognized or standardized type of roofing panel or system. The term "AG" could be an abbreviation for a specific manufacturer, product line, or regional terminology, but without more context or information, it's challenging to provide a detailed description.

To obtain accurate information about AG Roof Panels, you should consider the following steps:

- Manufacturer: Determine if there is a specific manufacturer associated with the AG Roof Panels you are interested in. Visit the manufacturer's website or contact them directly for detailed product information.

- Local Terminology: Roofing products and terms can vary regionally or locally. What is referred to as "AG" in one area may have a different name or abbreviation elsewhere. Make sure you are using the correct terminology for your location.

- Product Specifications: Review any product specifications, brochures, or documentation provided by the manufacturer or supplier. This documentation should contain detailed information about the AG Roof Panels, including their materials, dimensions, profiles, and features.

- Consult a Professional: If you are planning to purchase or install AG Roof Panels and need specific information or guidance, consider consulting a roofing professional or contractor with experience in your region. They can provide advice and recommendations based on local building codes and best practices.

- Online Research: Conduct online research using specific keywords related to the AG Roof Panels you are interested in. This might help you find more information or sources that provide details about these panels.

Remember that accurate and detailed information about a specific roofing product is essential for making informed decisions regarding its use in construction or renovation projects.