Cassette Quick Change Deck Roll Forming Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Quick change cassette steel deck roll forming machine with autostacker

- Footprint 120ft x 15ft

- 20,000lb Uncoiler

- Stands 28 gauges 16 to 22g

- Driven with 28 gearboxes and reducers

- Main motor 65hp 3ph 60hz

- Embosser stations with gear box drive station 25hp motor

- On and off embossing rollers

- Flying Hydralic shear and changing table

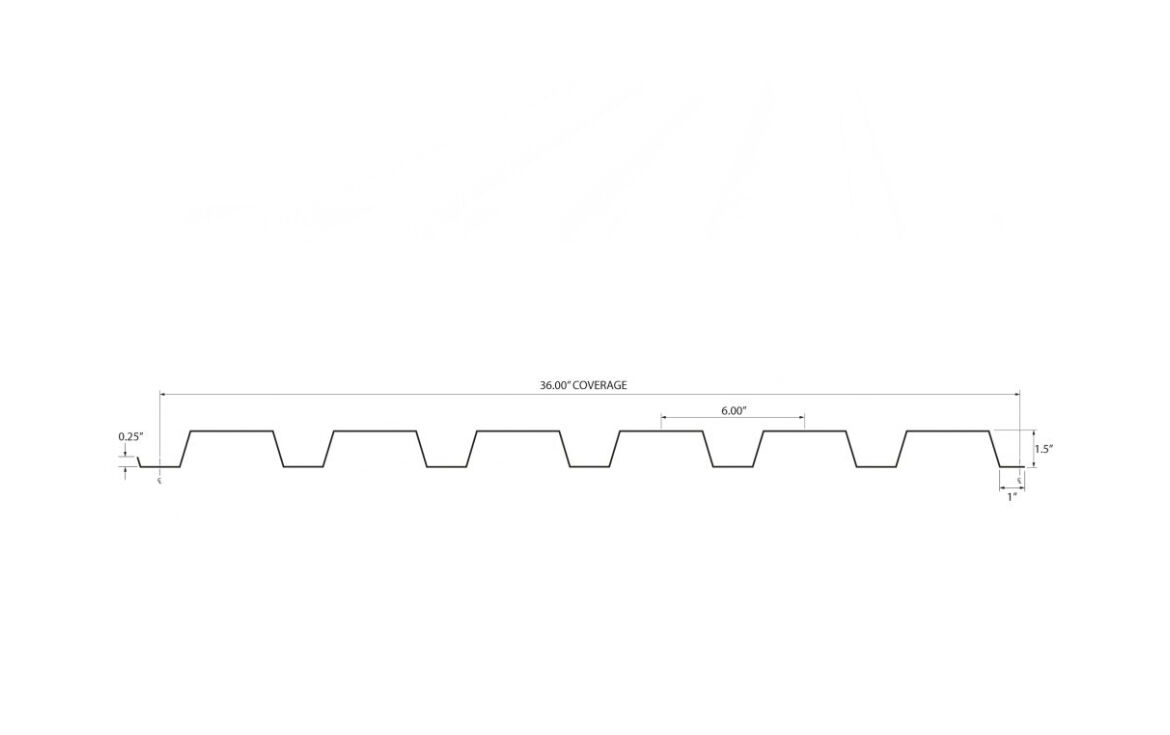

- Profiles are b deck 1-1/2" / Q deck 3" 4 ribs

- Coil width 48" +/-

- Computer controls Yasakawa

- Drive Fuji mmi Mitsubishi Plc

- E stops and safety fence

- Total machine weight 100 tons +/-

- 4 inch main shafts and 5 inch embossing shafts

The Cassette Quick Change Deck Roll Forming Machine is a high-performance, innovative solution designed for producing a wide range of metal deck profiles with exceptional precision and efficiency. This machine is ideal for construction and industrial applications, enabling manufacturers to produce durable, high-quality decks used in roofing, flooring, and other structural systems. Its advanced quick-change cassette system ensures minimal downtime and maximum versatility, making it a cost-effective investment for businesses seeking flexibility and scalability in production.

Key Features and Advantages

- Quick Change Cassette System:

The standout feature of this machine is its cassette quick-change design, allowing users to switch between different deck profiles swiftly. This reduces downtime, increases production efficiency, and provides versatility in handling multiple profiles. - High-Precision Rollers:

Equipped with precision-engineered rollers made from high-quality materials, the machine ensures consistent and flawless deck profiles. - Robust Construction:

The machine's heavy-duty frame guarantees stability and durability, ensuring smooth operation even under high-speed production conditions. - Advanced Control Systems:

Integrated with a PLC (Programmable Logic Controller) system, the machine offers user-friendly operation, real-time monitoring, and precise control over production parameters. - High-Speed Production:

With optimized engineering and cutting-edge technology, this machine is capable of achieving high production speeds while maintaining quality. - Customization Options:

It supports the production of various metal deck profiles, catering to specific market demands and project requirements. - Hydraulic Cutting System:

The hydraulic cutting mechanism ensures clean, precise cuts with minimal material wastage.

Specifications

- Roller Materials: Hardened steel with a chrome finish for extended durability and precision.

- Cassette System: Interchangeable for multiple deck profiles.

- Frame Size: Heavy-duty, vibration-resistant steel frame.

- Motors: High-power servo motors for seamless operation.

- Control System: Advanced PLC with a touchscreen interface.

- Machine Speed: Capable of reaching speeds up to 40 meters per minute (varies based on profile complexity).

- Safety Features: Equipped with safety guards and emergency stop systems.

- Hydraulic Cutting System: Ensures precise and efficient cuts.

- Material Thickness: Suitable for processing materials with a thickness range of 0.7mm to 1.5mm.

- Applications: Roofing, flooring, and structural metal decks for industrial and commercial projects.

Setup and Installation

The machine comes with comprehensive installation support, including:

- Detailed user manuals.

- On-site training and installation assistance from expert technicians.

- Initial calibration for accurate production.

Maintenance Requirements

To ensure optimal performance and longevity, the following maintenance practices are recommended:

- Regular lubrication of moving parts.

- Periodic inspection of rollers for wear and tear.

- Calibration of the PLC system.

- Replacement of hydraulic fluids as per the maintenance schedule.

Question and Answer Section

Q1: What is the primary advantage of the quick-change cassette system?

A1: The quick-change cassette system allows manufacturers to switch between different deck profiles quickly and efficiently, significantly reducing downtime and enhancing production versatility.

Q2: Can this machine handle thicker materials?

A2: Yes, the machine is designed to process materials with a thickness range of 0.7mm to 1.5mm, making it suitable for various deck applications.

Q3: What kind of maintenance does the machine require?

A3: Regular lubrication, inspection of rollers, calibration of the PLC system, and hydraulic fluid replacement are recommended for optimal performance.

Q4: Is the machine compatible with different types of metal materials?

A4: Yes, the machine can process a variety of metal materials, including galvanized steel and aluminum, as long as they fall within the specified thickness range.

Q5: How does the PLC system enhance the operation?

A5: The PLC system offers a user-friendly interface, precise control over production settings, and real-time monitoring, ensuring consistent and accurate results.

Q6: Can this machine be customized for specific deck profiles?

A6: Absolutely. The machine supports customization to produce a variety of deck profiles, making it adaptable to market and project-specific needs.

Q7: Does the machine include safety features?

A7: Yes, the machine is equipped with safety guards and emergency stop systems to ensure operator safety.