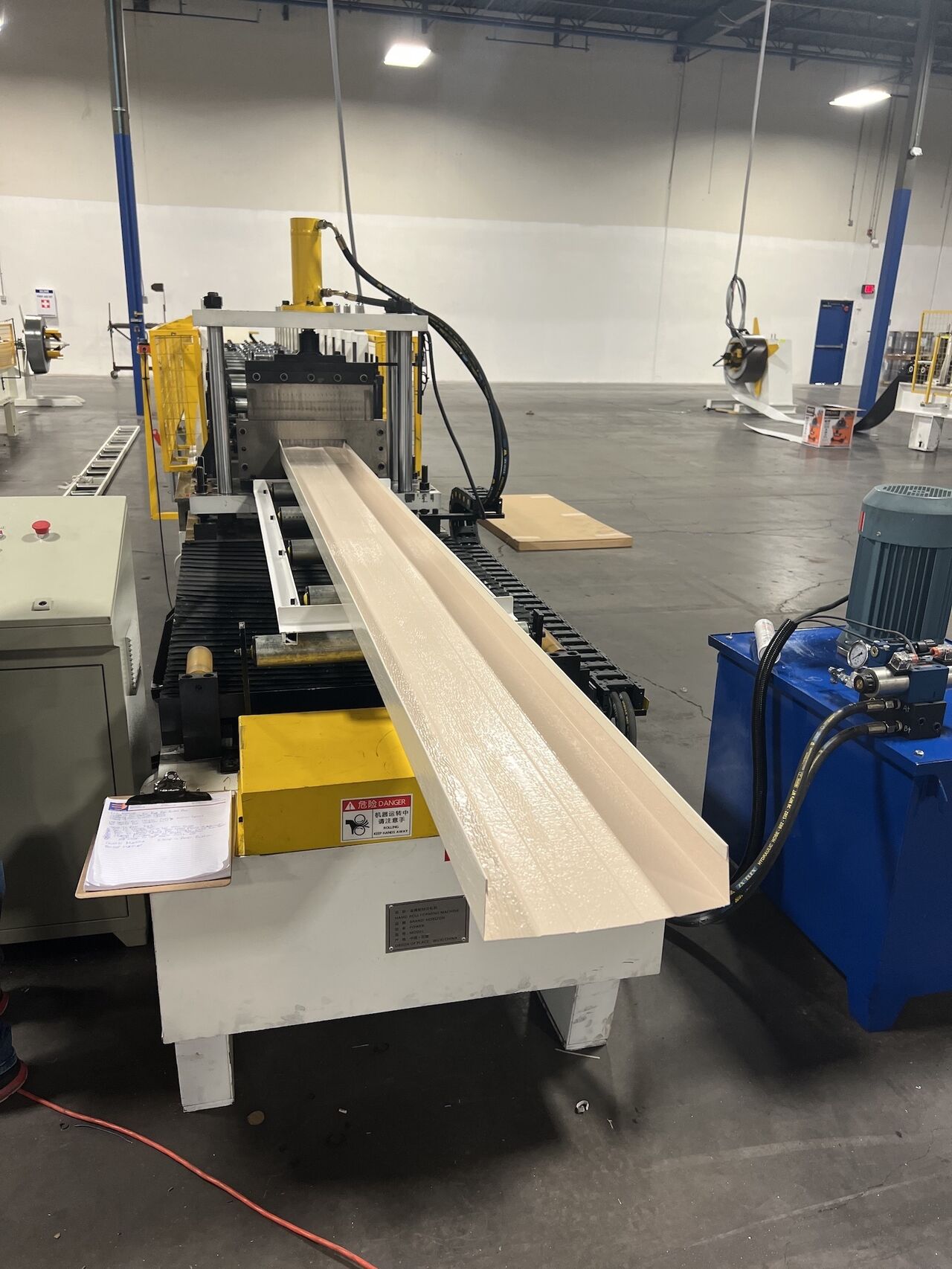

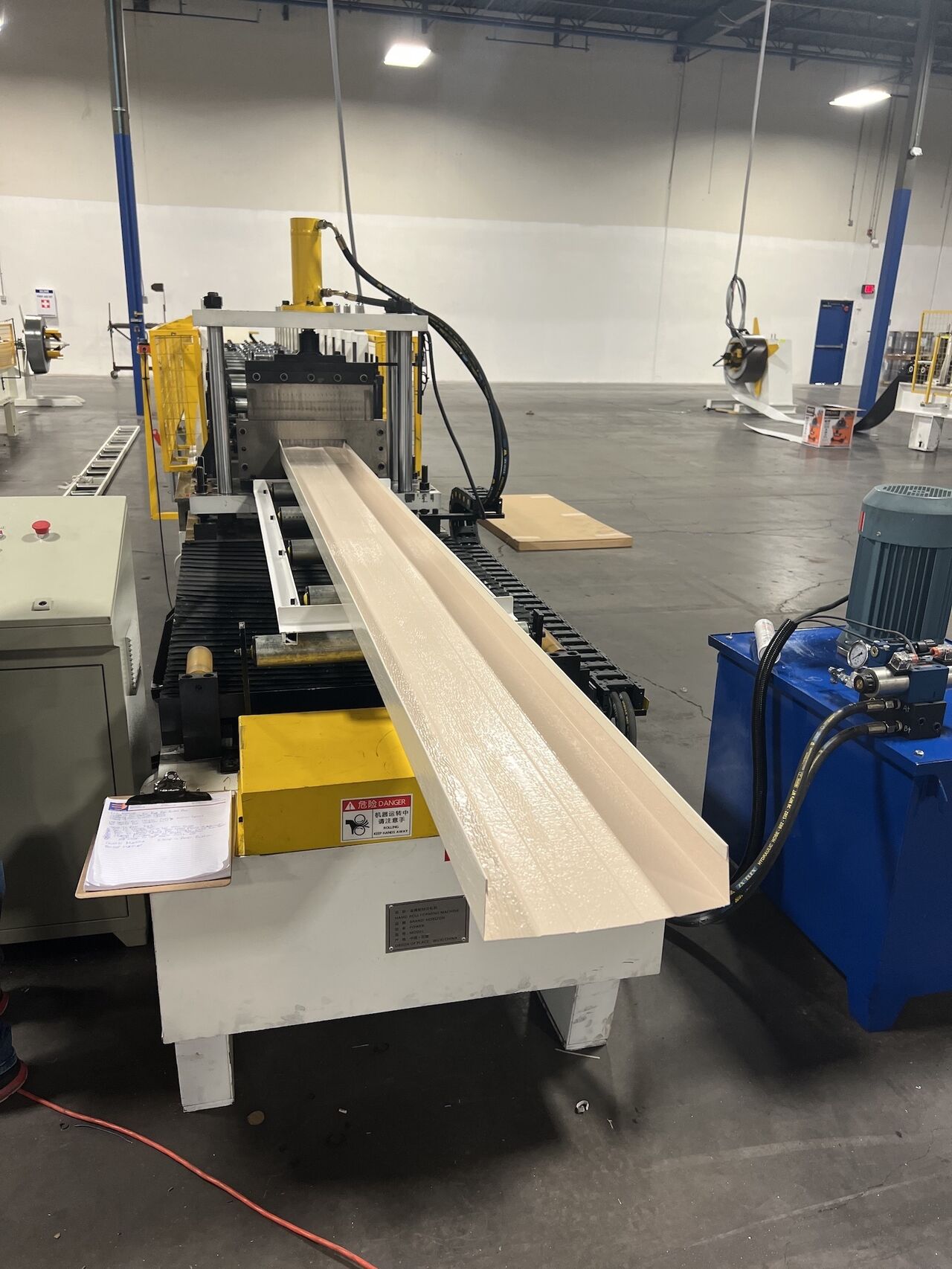

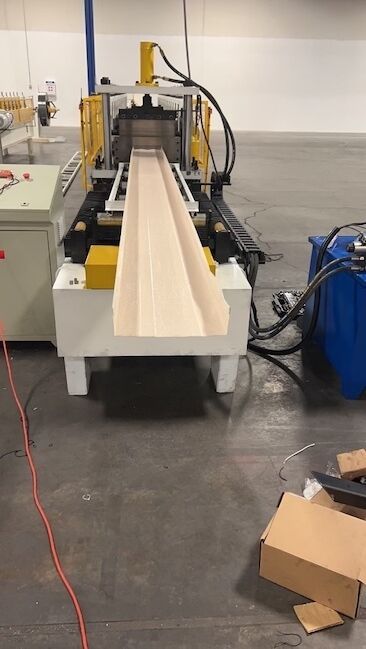

Fan Cap Fascia Cover Roll Forming Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Fan Cap Fascia Cover Roll Forming Machine Specifications

- 8" Fan Cap Fascia Cover

- Foot print 36 ft x 6ft

- Power 240v 3ph 60 Hz

- Hydraulic Flying Shear or Cam Shear

- 2" Shafts Heat Treated Tooling With Hard Chrome

- CNC Controls Read Out In Inches

Fascia Cover Roll Forming Machine Description

A Fan Cap Fascia Cover Roll Forming Machine is a specialized piece of equipment used in manufacturing processes to create fan cap fascia covers through a process known as roll forming. Let's break down the key components and processes involved:

- Roll Forming: Roll forming is a continuous metal forming process that involves feeding a metal strip or coil through a series of rollers. Each roller progressively shapes the metal into the desired profile. This process is particularly useful for producing long and uniform metal components with complex cross-sections.

- Fan Cap Fascia Cover: The fan cap fascia cover is a metal cover or shield designed to protect various types of fans or ventilation systems. It is usually custom-designed to fit specific fan models and can have various shapes and features to accommodate different installation requirements.

- Roll Forming Machine: The roll forming machine used to manufacture fan cap fascia covers is specifically designed for this purpose. It consists of a series of rollers and other equipment that work together to transform a flat metal strip or coil into the desired fan cap fascia cover profile.

Here's how the process typically works:

- Material Feeding: A metal strip or coil is loaded into the roll forming machine. This material is often made of materials like steel or aluminum, depending on the application.

- Roller Setup: The roll forming machine is set up with a series of rollers, each with a specific shape or contour. These rollers are positioned along the production line in the order required to gradually form the metal into the fan cap fascia cover profile.

- Roll Forming Process: As the metal strip or coil passes through the machine, it is gradually bent and shaped by the rollers. The roller configurations can be adjusted to create the desired features and dimensions of the fan cap fascia cover.

- Cutting and Finishing: After the metal has been roll-formed into the correct shape, the machine may include additional processes such as cutting to length and any necessary finishing operations, like punching holes or adding folds, to complete the fan cap fascia cover.

- Quality Control: Quality control measures are typically in place to ensure that each fan cap fascia cover meets the specified tolerances and quality standards.

- Packaging: Once the fan cap fascia covers are manufactured and inspected, they are typically packaged and prepared for shipment to customers.

In summary, a Fan Cap Fascia Cover Roll Forming Machine is a specialized piece of equipment used in the metalworking industry to manufacture custom-shaped metal covers for various types of fans and ventilation systems. It employs the roll forming process to gradually shape metal strips or coils into the desired fan cap fascia cover profiles.