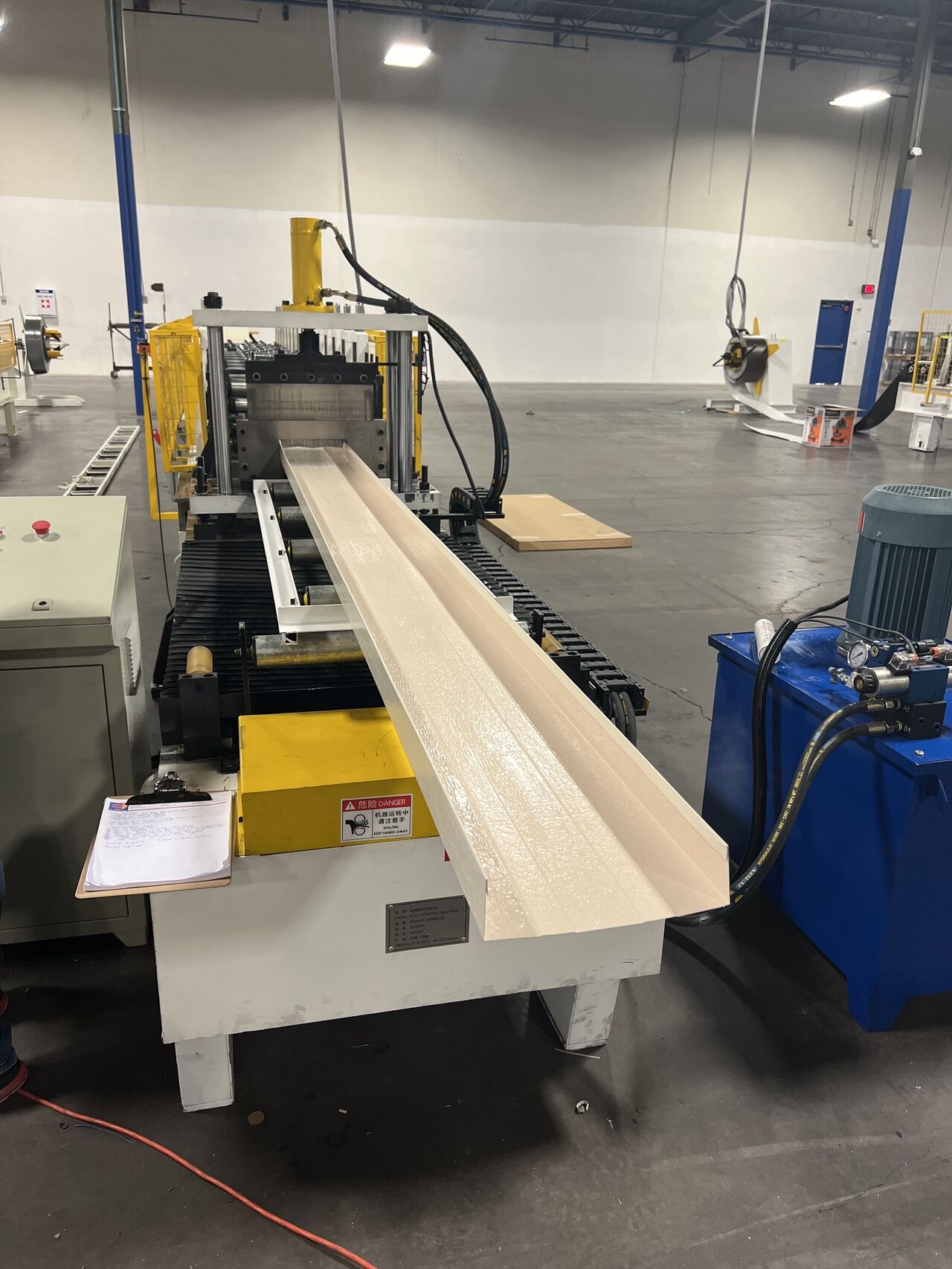

Fan Cap / Facia Metal Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Metal Facia Roll Forming Machine Specifications

- Profile: 8" x 2"

- Coil Width - 13.5"

- Forming Speed - 70ft - 80ft per min

- Material thickness - 0.27 - 0.32

- Machine Weight - 6 ton

- Machine Footprint - 34ft x 3ft

- Main power - 240v 3ph

- Motor - 10Hp

- Gearbox - chain drive

- Stations - 22

- Cutting type - electric shear

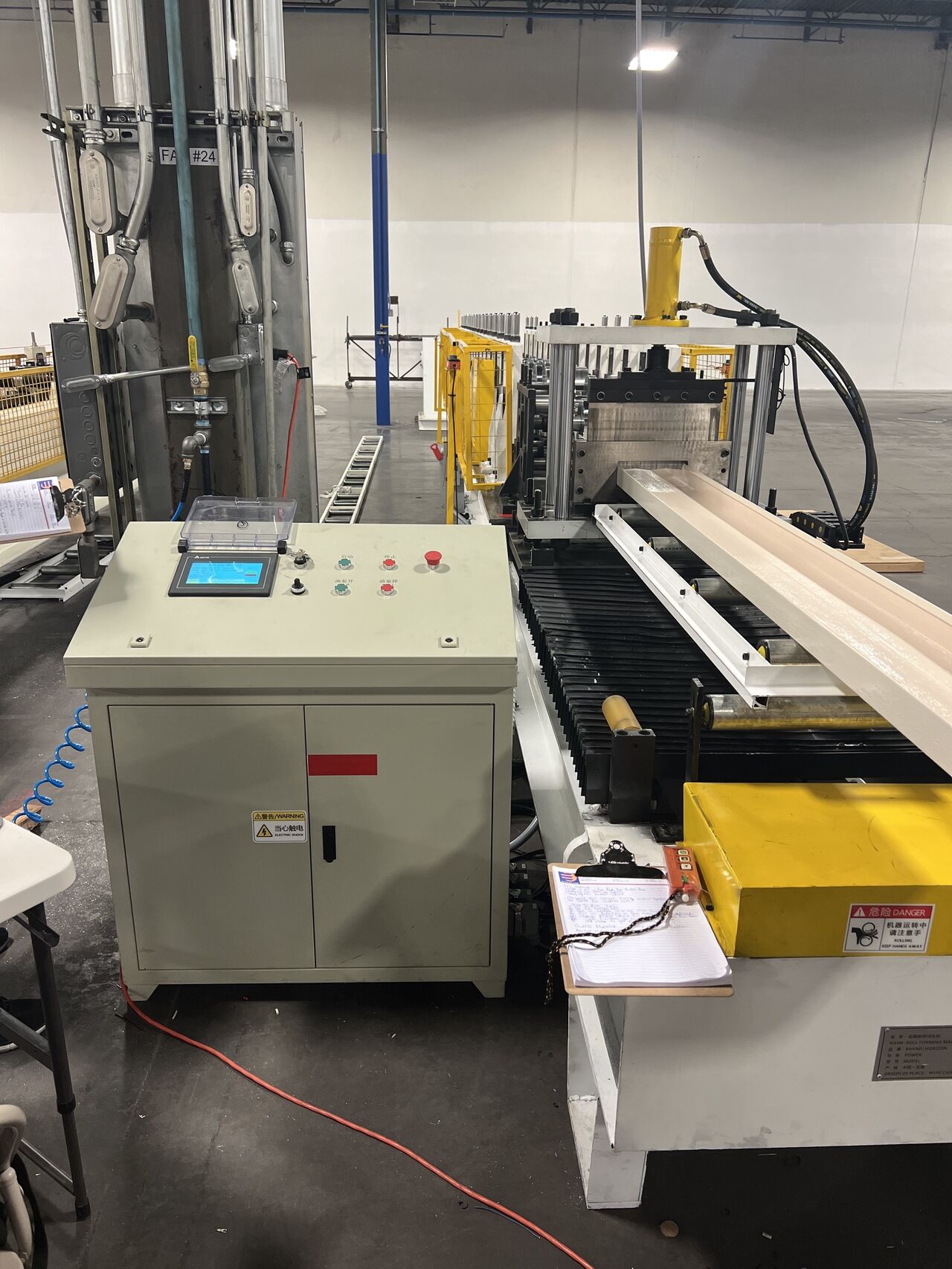

- Control system - delta

- Safety covers- optional

- E Stops

- FOB Orlando, Florida

Metal Facia Roll Forming Machine Description

A metal fascia roll forming machine is a specialized piece of equipment used in the manufacturing and construction industry to produce metal fascia panels or trim components. Fascia is typically installed along the roofline of a building to cover and protect the edges of the roof and the underlying structure. These panels are often made from materials such as aluminum, steel, or other metals, and they come in various profiles and styles to suit different architectural designs and functional requirements.

Here's how a metal fascia roll forming machine works:

- Material Feeding: The roll forming machine starts by feeding a coil of metal sheet or strip into the machine. This coil can be made from various metals, depending on the desired characteristics and aesthetics of the fascia.

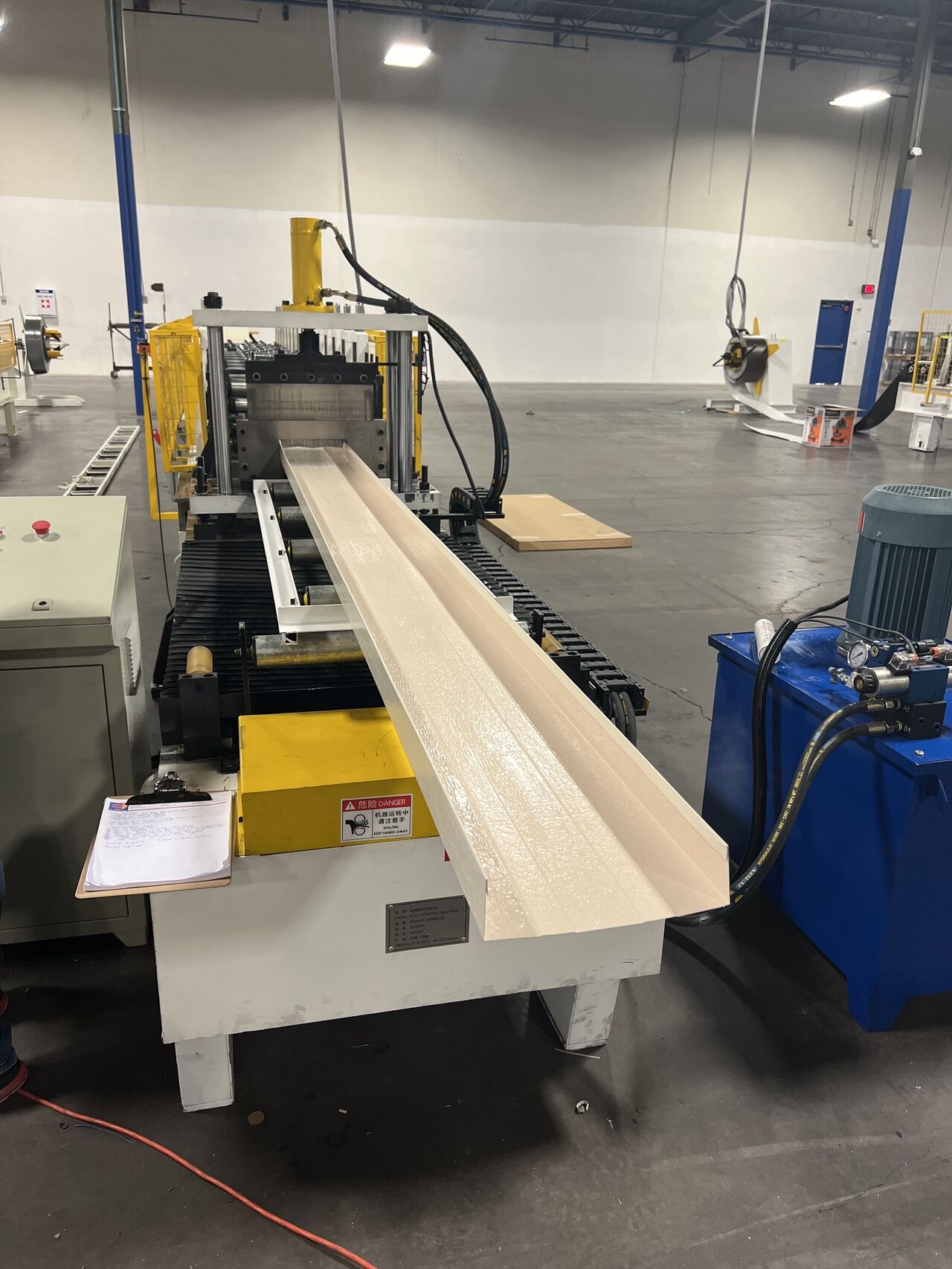

- Roll Forming: The machine consists of a series of rollers and tooling sets that gradually shape the flat metal sheet into the desired profile of the fascia panel. Each set of rollers or forming stations performs a specific bending or shaping operation, and the material passes through these stations sequentially.

- Cutting and Length Control: After the metal has been roll-formed into the desired profile, the machine may have a cutting mechanism that trims the panel to the required length. Some machines also have automatic length control systems to ensure that each panel is cut to the correct size.

- Stacking or Output: Once the panels are cut to the appropriate length, they are typically stacked or collected for further processing, packaging, or transportation.

These machines are highly automated and can produce large quantities of metal fascia panels quickly and efficiently. They are commonly used in the construction industry, especially for residential and commercial roofing projects.

The specific features and capabilities of a metal fascia roll forming machine can vary depending on the manufacturer and the intended application. Some machines may have additional features such as embossing, perforating, or coating capabilities to enhance the appearance and functionality of the fascia panels.

When using such machines, it's important to follow safety protocols and ensure proper maintenance to maximize their lifespan and productivity. Additionally, the choice of materials and the design of the roll forming profile should be carefully considered to meet the project's requirements and aesthetic preferences.

All roll forming machinery is fully assembled at our factory in Orlando Florida. and comes with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

To request a quote or If you have any questions about our machines, please fill out the contact form below.