Drip edge stop and shear machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Drip Edge Stop and Shear Roll Forming machine Specifications

- weight 2500lbs

- size 15ft 10 stands hydraulic shear

- power electric 240v three phase 60 Hz

- materials include galvanized, galvalume, aluminum and copper

All roll forming machinery is fully assembled at our factory in Orlando Florida. Our Roll Forming Machines come with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

Drip Edge Stop and Shear Roll Forming machine Description

A "Drip Edge Stop and Shear Roll Forming Machine" appears to be a specialized piece of equipment used in the manufacturing or construction industry. Let's break down the components of the name to understand what this machine might be designed for:

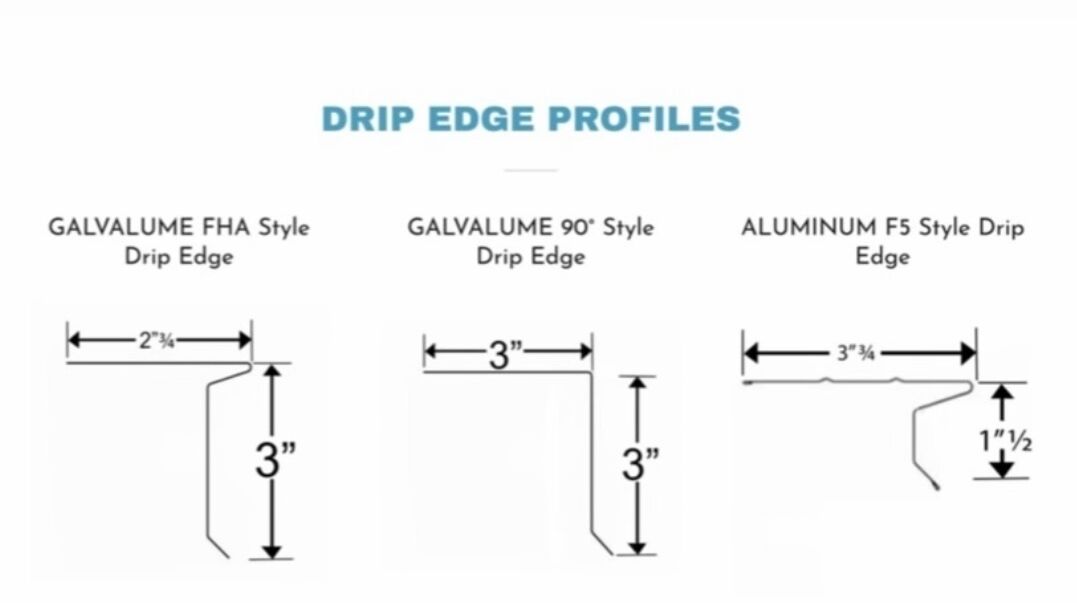

- Drip Edge: A drip edge is a type of roofing component used to direct water away from the fascia of a building and prevent water damage. It's commonly used in roofing systems to protect the roof's edges from water infiltration.

- Stop: In the context of construction or manufacturing, a "stop" can refer to a device or part used to halt, guide, or hold materials or components in place during a manufacturing or assembly process.

- Shear: "Shear" usually refers to a cutting action. In metalworking or roll forming, it may be used to describe the process of cutting or trimming a metal sheet or coil into specific shapes or lengths.

- Roll Forming Machine: Roll forming is a metalworking process where a long strip of metal is passed through a series of rollers to gradually shape it into a desired profile or cross-section. Roll forming machines are used extensively in the manufacture of various products, especially those that require long, continuous shapes.

Considering these components, a "Drip Edge Stop and Shear Roll Forming Machine" may be a specialized roll forming machine designed for the production of drip edges used in roofing systems. It could incorporate features for precise shaping, cutting, and possibly even bending or folding of metal strips into the specific profile required for drip edges. The "stop" in the name might indicate that the machine has features to halt or guide the material during the roll forming process, ensuring accurate and consistent results.

Please note that specific machine designs and capabilities can vary widely depending on the manufacturer and the intended application, so it's essential to refer to the machine's documentation or the manufacturer's specifications for precise details on its functionality and operation.

Please note: Roll Forming Machines LLC does not provide in-house financing, but the leasing companies listed here can assist with financing our equipment. Roll Forming Machines LLC is not affiliated with any of these companies.

To request a quote or If you have any questions about our machines, please fill out the contact form below.