Drip Edge Roll Forming Machine

To request a quote or if you have any questions about our machines, please fill out the online contact form below or download the quote form and send to [email protected].

RFM ENQUIRY FORM .pdf file

Please be as detailed as possible in your message including technical information, profile needed, gauge of material, power supply requirements, shipping location etc.

Drip Edge Machine Specifications

- weight 2500lbs

- size 18ft x 3 x 5ft

- power electric 240v three phase 60 Hz

- materials include galvanized, galvalume, aluminum and copper

- Speed 80ft minute

- size 15ft 10 stands

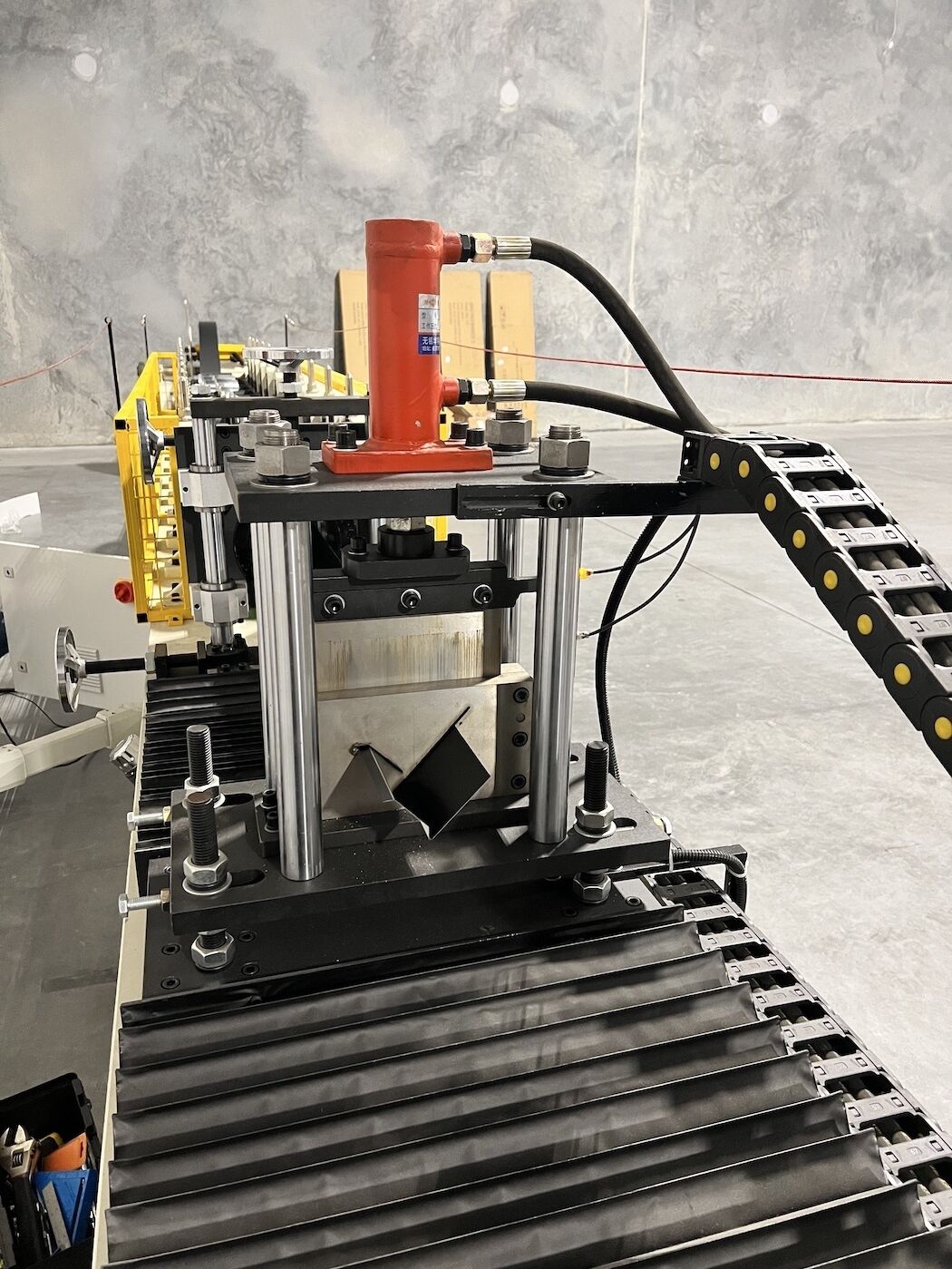

- hydraulic shear

Drip Edge Roll Forming Machine Description

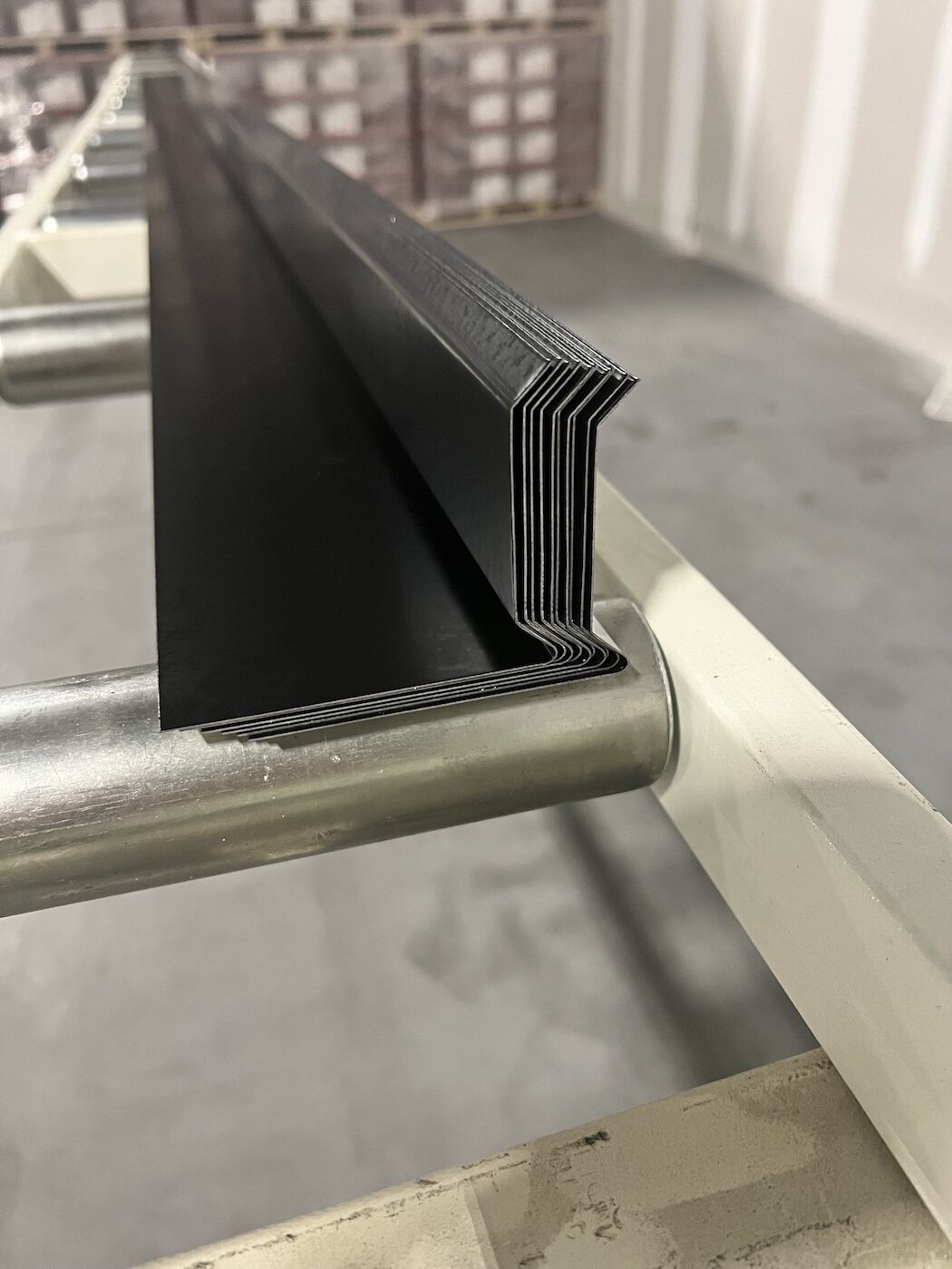

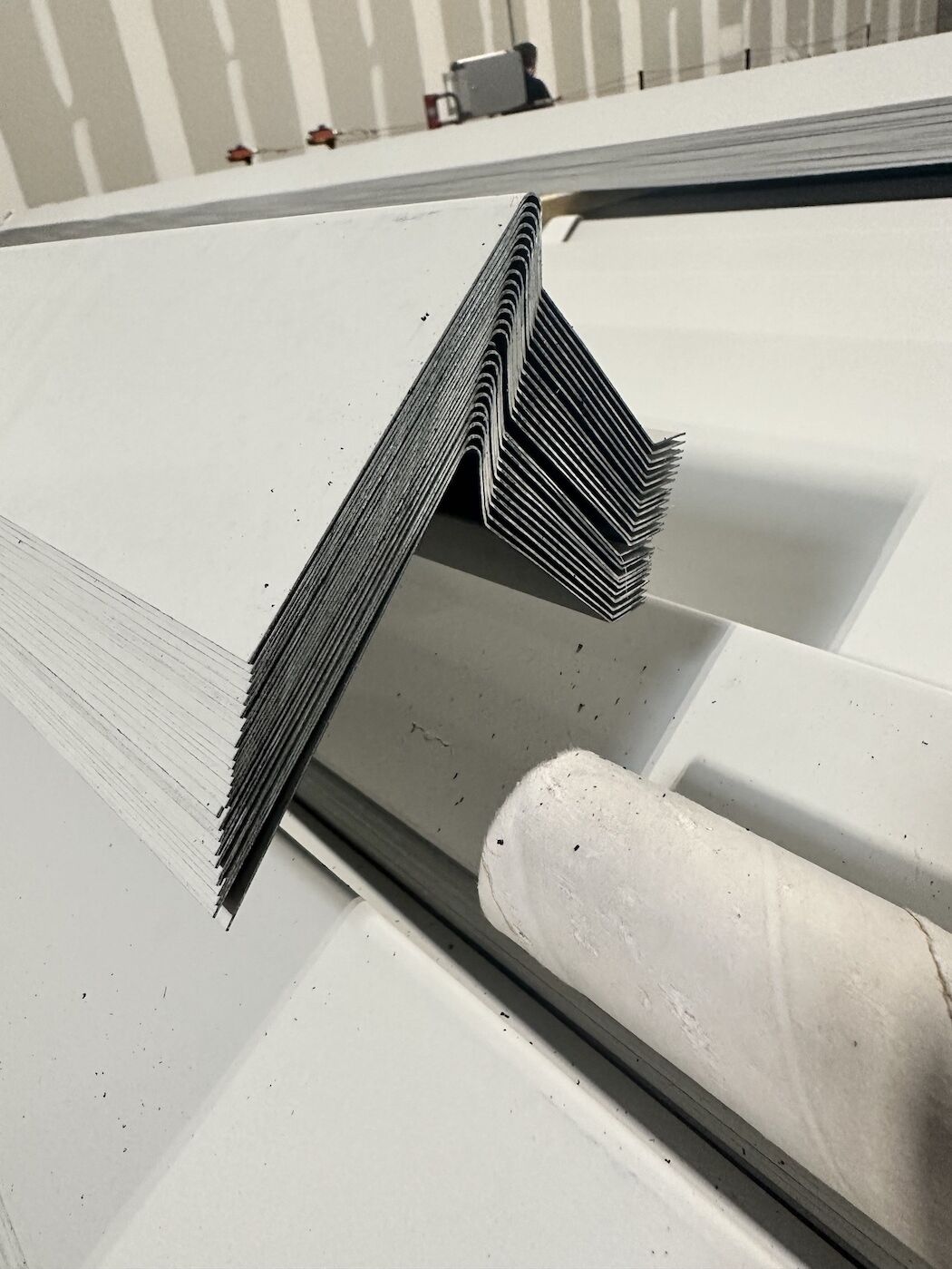

A Drip Edge Roll Forming Machine is a specialized piece of equipment used in the construction and roofing industry to produce drip edges, which are essential components for roof installations. Drip edges are metal strips that are installed along the edges of a roof to protect it from water damage and help direct rainwater away from the structure. These machines automate the process of manufacturing drip edges by continuously forming and shaping metal sheets into the desired profiles.

Here is a description of the key features and components of a typical Drip Edge Roll Forming Machine:

- Material Feeding System: The machine typically starts with a material feeding system that allows operators to load metal coils or sheets onto the machine. These coils are usually made of galvanized steel, aluminum, or other metals commonly used in roofing applications.

- Roll Forming Stations: The heart of the machine consists of multiple roll forming stations. Each station is equipped with a set of rolls and tooling designed to gradually shape the metal sheet into the desired drip edge profile. These stations work in sequence, with each station performing a specific shaping operation. The number of stations can vary depending on the complexity of the drip edge profile.

- Drive System: Roll forming machines are equipped with a robust drive system, which includes motors and gears, to move the metal sheet through the roll forming stations at a controlled speed. The drive system ensures precise and consistent forming of the metal.

- Cutting Mechanism: After the metal sheet has been shaped into the drip edge profile, a cutting mechanism is employed to trim the formed strip to the required length. This ensures that each drip edge is uniform in size.

- Control Panel: Modern drip edge roll forming machines are often equipped with a user-friendly control panel that allows operators to set parameters such as speed, length, and the desired drip edge profile. The control panel also provides information on the machine's operation and status.

- Material Guiding and Support: Throughout the forming process, the machine may have various guides, rollers, and support systems to keep the metal sheet aligned and prevent deformation or wrinkling.

- Stacking or Packaging System: Some machines come with additional features for automatically stacking or packaging the finished drip edges, making the production process more efficient.

Drip Edge Roll Forming Machines are versatile and can be customized to produce various drip edge profiles to meet different roofing requirements. They are known for their efficiency, precision, and the ability to produce high-quality drip edges in large quantities, making them essential equipment for roofing and construction companies.

It's important to note that the specific features and capabilities of a Drip Edge Roll Forming Machine may vary depending on the manufacturer and model, so it's advisable to consult the machine's user manual and the manufacturer's specifications for detailed information about a particular machine.

All roll forming machinery is fully assembled at our factory in Orlando Florida. Our Roll Forming Machines come with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

Please note: Roll Forming Machines LLC does not provide in-house financing, but the leasing companies listed here can assist with financing our equipment. Roll Forming Machines LLC is not affiliated with any of these companies.

To request a quote or If you have any questions about our machines, please fill out the contact form below.