Custom Drip Edge Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Custom Drip Edge Machine Specifications

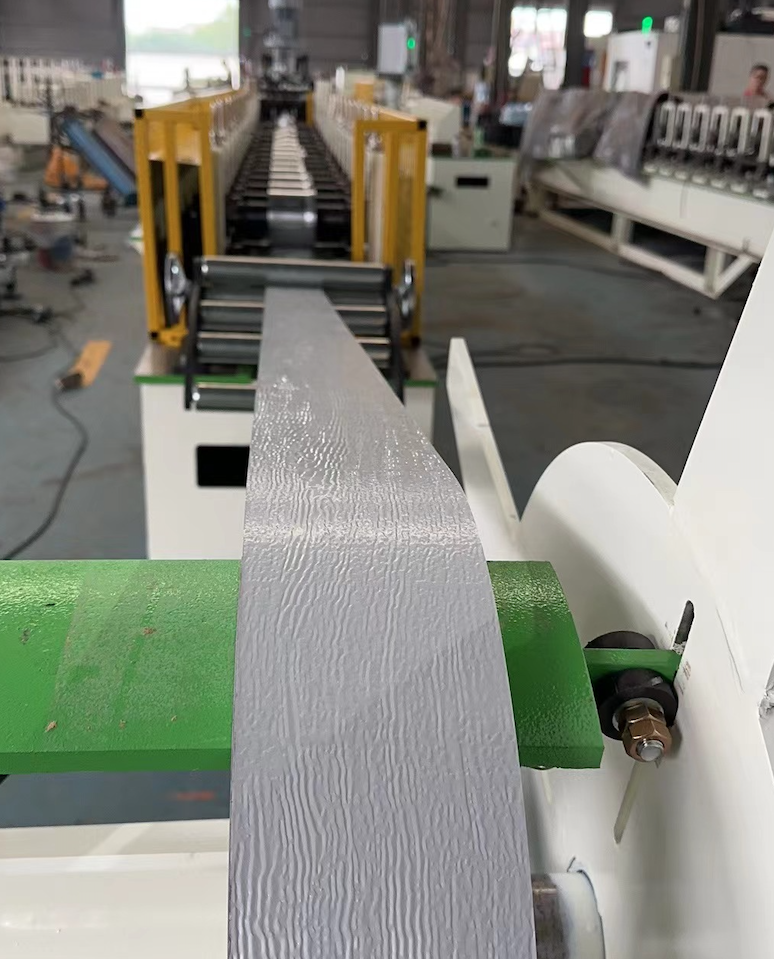

- 1 1/2" Drip Edge Profile

- Weight: 2500lbs

- Machine size: 18ft x 3 x 5ft

- Power: electric 240v three phase 60 Hz

- materials:

- Speed: 80ft minute

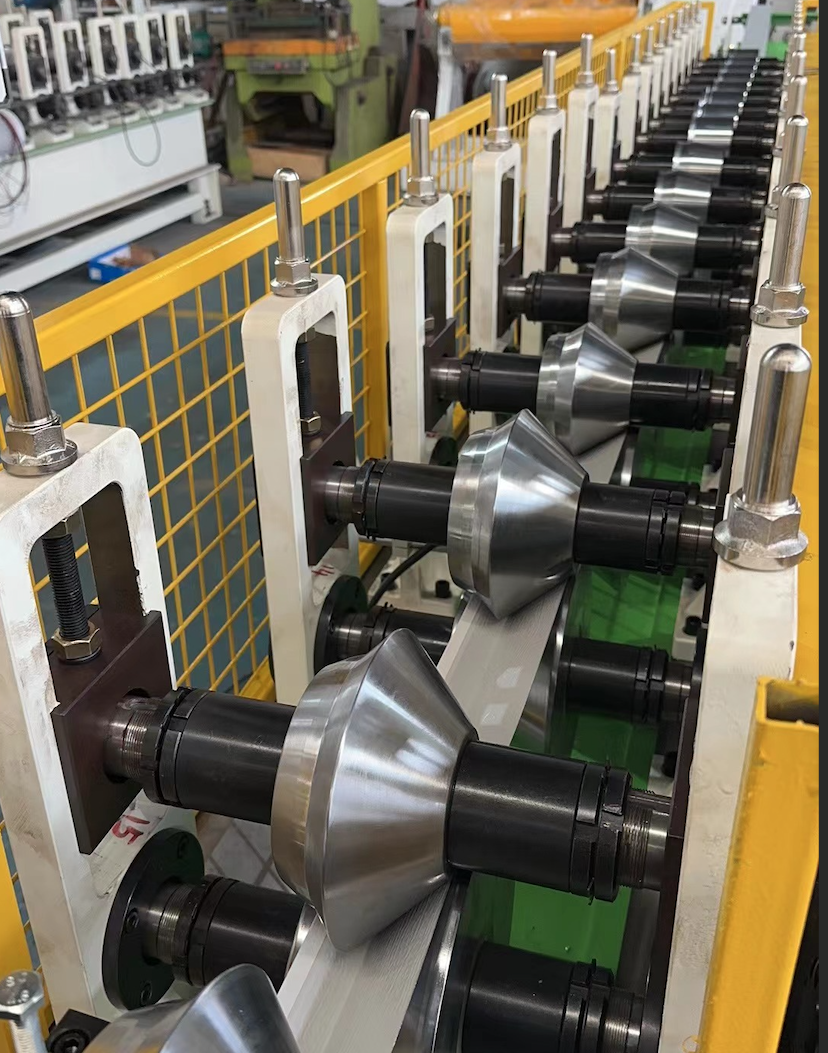

- 10 stands

- Electric shear

All roll forming machinery is fully assembled at our factory in Orlando Florida. Our Roll Forming Machines come with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

Custom Drip Edge Roll Forming Machine Description

A metal drip profile roll forming machine is a piece of industrial equipment used in the manufacturing of metal drip profiles. Drip profiles, also known as drip edges or gutter profiles, are metal strips or channels typically used in roofing and construction to direct water away from critical areas and prevent water damage.

The roll forming process involves feeding a metal coil through a series of rollers and dies that progressively shape the metal into the desired profile. In the case of a metal drip profile roll forming machine, it is designed specifically to produce drip profiles with a consistent shape and dimensions.

These machines are highly automated and can produce drip profiles at a high rate, ensuring uniformity and precision in the final products. Metal drip profiles are crucial for protecting buildings from water damage by guiding rainwater away from vulnerable areas, such as roof edges, eaves, and corners. The use of a roll forming machine helps manufacturers produce these profiles efficiently and cost-effectively.

Drip Edge Profiles

In the context of construction in the USA, a metal drip profile, also known as a drip edge or drip edge flashing, is a type of metal flashing used primarily in roofing applications. Its main purpose is to direct water away from vulnerable areas of a roof, such as the edges, eaves, and corners, to prevent water from infiltrating the building structure and causing damage.

Here are some key functions and features of metal drip profiles in the USA:

- Water Diversion: Metal drip profiles are installed along the edges of a roof to help channel rainwater away from the roof and into the gutters or off the roof's edge. This prevents water from running down the fascia, soffit, or walls of a building, which could lead to moisture-related issues and rot.

- Protection: Drip edges provide protection to the roof deck and underlayment by preventing water from seeping underneath the roofing materials.

- Wind Resistance: They also serve to protect the roof from wind uplift, helping to keep the roofing materials in place during strong winds.

- Enhanced Aesthetics: Drip edges can enhance the appearance of the roof by providing a finished, clean edge.

Typically, metal drip profiles are made from materials like galvanized steel, aluminum, or stainless steel, which are known for their durability and resistance to corrosion. They come in various shapes and sizes, with L-shaped and T-shaped profiles being common options. The specific design and requirements for drip edges may vary by local building codes and roofing practices.

The installation of drip edges is considered a standard practice in roofing construction in the USA, as it helps protect buildings from potential water damage and contributes to the overall longevity of the roof. Properly installed drip edges are an essential component of a well-constructed roofing system.