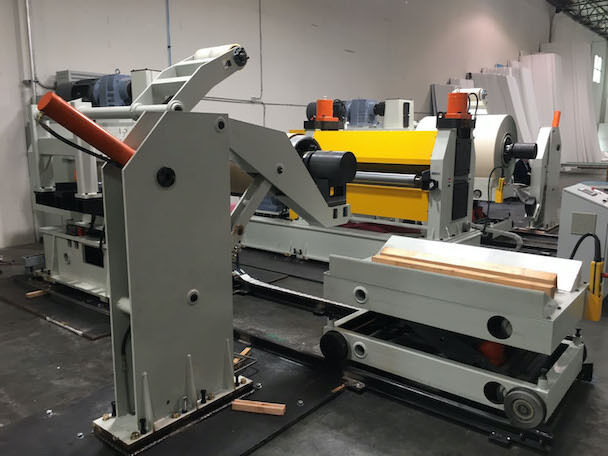

Coil Embosser Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

Coil Embosser Machine Specifications

- Coil Width - Variable

- Forming Speed - 60 - 70ft

- Material thickness - 0.19 - 0.40

- Machine Weight - depending on coil size

- Machine Footprint - 30ft x 15ft

- Main power - 480v - 3ph - 60Hz

- Motor - 25Hp

- Cutting type -

- Control system - Delta

- Safety covers- Yes

- E Stops

- FOB Orlando, Florida

Coil Embosser Machine Description

A coil embosser machine, also known as a coil embossing machine or coil embosser, is a piece of equipment used to create embossed patterns or designs on metal coils or strips. This process is often used in the manufacturing of decorative or functional metal products, such as sheet metal for architectural purposes, automotive trim, signage, and various other applications.

Here's a basic overview of how a coil embosser machine works:

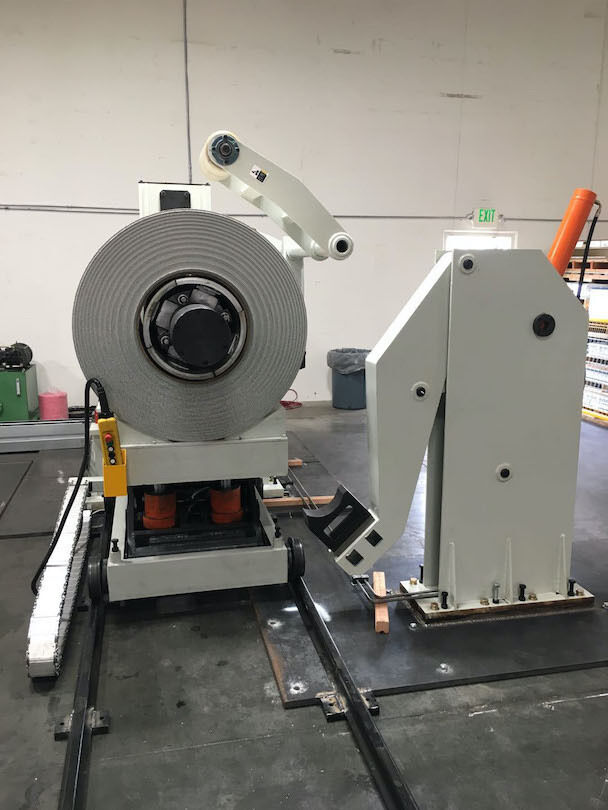

- Material Feed: The machine starts with a roll or coil of metal material, such as aluminum, stainless steel, or other metals. This material is typically unembossed at the beginning of the process.

- Feeding System: The metal coil is fed through a series of rollers or guides that help control the movement of the material through the machine.

- Embossing Rolls: The heart of the coil embosser machine is a set of embossing rolls. These rolls have raised patterns or designs engraved on their surfaces. The embossing rolls press against the metal strip as it passes through, creating the desired embossed pattern on the metal surface. The rolls can be customized to produce different patterns or designs depending on the application.

- Pressure and Temperature: Some coil embossers may apply heat and pressure to the metal strip to facilitate the embossing process, especially when working with harder metals. The exact temperature and pressure settings can vary depending on the material being embossed.

- Cooling and Inspection: After the embossing process, the embossed metal strip may go through a cooling stage to set the pattern. It is then inspected for quality control to ensure that the embossed pattern meets the desired specifications.

- Cutting and Coiling: Once the embossing is complete and the material has cooled and passed quality checks, it can be cut to the desired length and coiled or packaged for further processing or shipment.

Coil embossing machines come in various sizes and configurations to accommodate different types and sizes of metal coils. They are widely used in industries where decorative or textured metal surfaces are required, such as construction, automotive, appliance manufacturing, and more.

Keep in mind that the specific features and capabilities of coil embossing machines may vary depending on the manufacturer and the intended application.

All roll forming machinery is fully assembled at our factory in Orlando Florida. Our Roll Forming Machines come with a 1 year warranty for parts and labor. All machines will be made to customer personal requirements and profile.

To request a quote or If you have any questions about our machines, please fill out the contact form below.