CNC Metal Folder Machine

Get a Quote

Send us a message and we’ll get back to you shortly.

CNC Metal Folder Machine Specifications

- Bending width 13ft long

- Hydraulic motor and clamps

- Box & pan operation

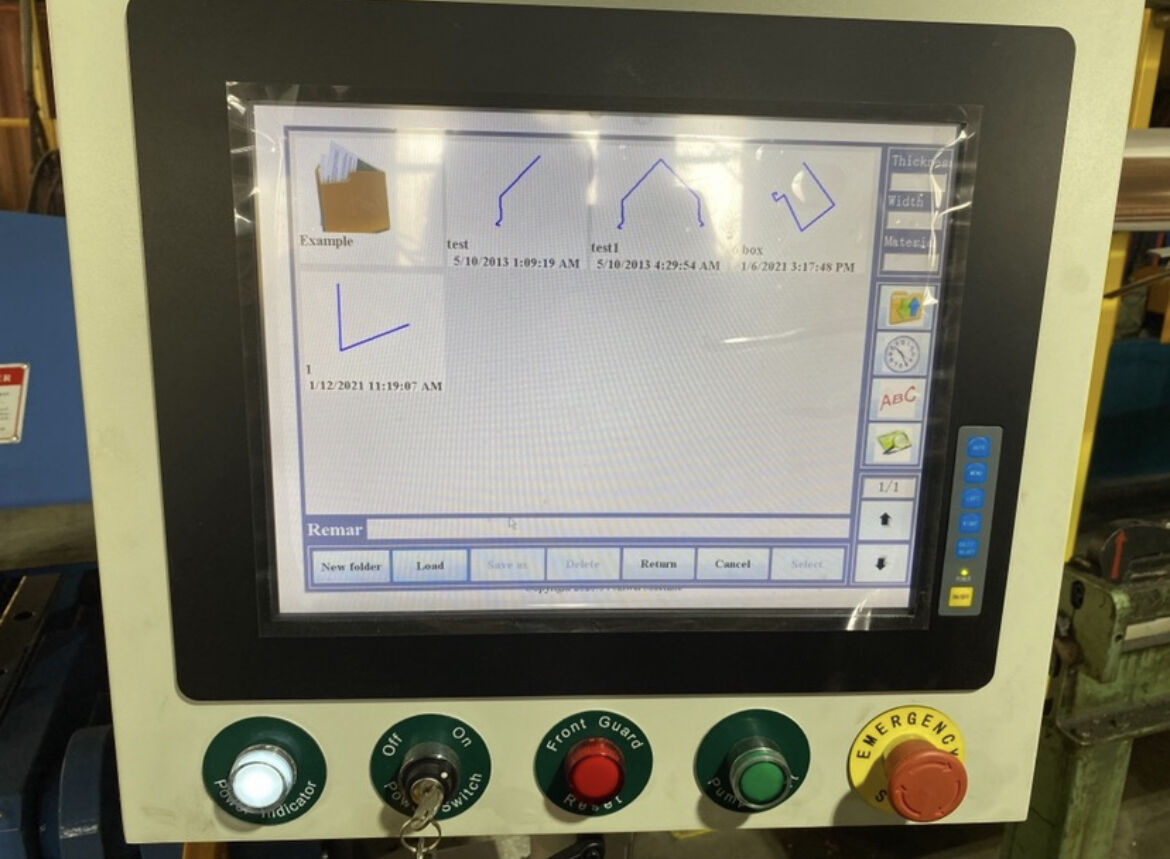

- Computer controls

- Servo back gauge with adjustable fingers

- Safety light sensor

- Foot print

- Weight

- 240v 3ph 60hz

- Back gauge bristle brush support

CNC Metal Folder Machine Description

A CNC metal folder machine, also known as a CNC press brake, is a versatile piece of equipment used in metal fabrication and sheet metal processing industries. It is designed to bend and shape metal sheets and plates accurately and efficiently. The "CNC" in its name stands for Computer Numerical Control, which means that the machine's operations are automated and controlled by a computer program.

Here are some key features and aspects of a CNC metal folder machine:

- Bending Capability: CNC metal folder machines are primarily used for bending metal sheets and plates. They can create various bend angles and shapes, including sharp angles and curves, by precisely controlling the position and force of the bending tool.

- CNC Control: These machines are equipped with a CNC control system that allows operators to input the desired bending parameters, such as bend angle, bend radius, and material thickness. The CNC system then controls the machine's movements and adjustments to achieve the desired bend.

- Tooling: CNC metal folder machines use a variety of tooling options, including punches and dies, to shape the metal. The choice of tooling depends on the specific bending requirements and the type of material being processed.

- Precision and Accuracy: CNC control ensures high precision and repeatability in bending operations. This is crucial for maintaining consistent product quality in metal fabrication.

- Versatility: These machines can work with various types of metals, including steel, aluminum, stainless steel, and more. They are used in a wide range of industries, from automotive and aerospace to construction and manufacturing.

- Safety Features: CNC metal folder machines are equipped with safety features to protect operators and prevent accidents. These may include light curtains, emergency stop buttons, and interlocks.

- Sheet Handling: Some CNC metal folder machines come with sheet handling systems that can automatically load and position metal sheets for bending, improving efficiency and reducing manual labor.

- Programming: Operators can create bending programs using CAD/CAM software, which generates CNC code for the machine to follow. This allows for complex and intricate bending patterns.

- Production Efficiency: CNC control and automation help increase production efficiency, reduce setup times, and minimize scrap material, leading to cost savings.

- Maintenance: Regular maintenance is essential to keep the machine in good working condition. This includes lubrication, inspection of tooling, and calibration of the CNC system.

CNC metal folder machines are essential equipment in modern metal fabrication shops, where they play a crucial role in producing a wide range of products, from brackets and enclosures to components for machinery and structures. Their precision, versatility, and automation capabilities make them valuable assets in the manufacturing industry.