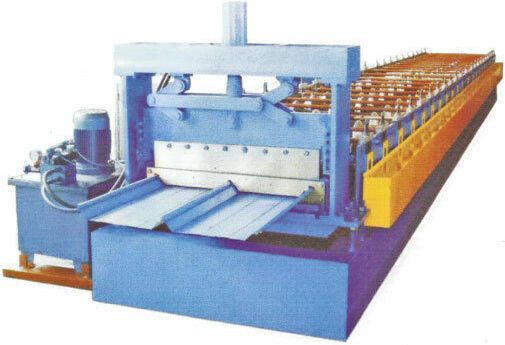

Standing Seam Metal Roof Machine

These machines are used to make standing seam metal roofing panels. These machines create double-standing seam locks for the roofing panels.

Posted on Wednesday, June 29, 2022

Double standing seam roofing - the benefits

Double standing seam roofing is popular, thanks to its high water resistance. The double seam prevents water from permeating under the closed double-standing roofing panels where they contact each other. This is down to the unique shape of the lock.

A standing seam metal roof machine creates panels that cover one another where they meet. When installing these panel types on a roof, they are closed using particular tools to ensure the panels are entirely watertight.

Additional benefits of a standing seam metal roof include:

Durability - this roof type is particularly robust and will last a long time, making it excellent value for money. Curb appeal - a standing seam metal roof can be an innovative and attractive choice for a property and could increase the property's value too. Fire resistance - metal is an extremely fire-resistant material Low maintenance - a standing seam metal roof requires little upkeep. A range of materials and colors - there is a wide choice of metals that can be used to create a standing seam metal roof, so you can pick the material and color that matches your desired aesthetic. Energy efficiency - this roof type boasts good energy efficiency and could save you money on heating bills, making it better for the environment. Suitable for low slope roofs - a standing seam metal roof can be used on roofs with a low pitch too.

Standing seam roll forming machines - how do they work?

An additional advantage of a standing seam metal roof machine is that it the width of the panels can be adjusted very easily to fit various project requirements. Different types of metals can also be fed into the machine, such as galvanized steel, steel coated, zinc, and titanium. The metal is fed into the machine and passed through the rollers, which bend and shape into the double-standing seam roofing panels.

This standing seam roofing machine has six pairs of rolls that form the shape of the double standing seam roofing panels and can be cut to precise lengths at the end.

Are standing seam metal roofs more expensive?

While standing seam metal roofs cost more, they remain a popular choice thanks to their excellent durability and waterproofing. This roof type remains the premier choice when it comes to residential metal roofing.

Standing seam metal roof machines from roll forming LLC

If you are looking for a robust, reliable standing seam metal roof roll forming machine, browse the range from Rollforming LLC, or get in touch with our customer team to discuss your needs today.

Uncoiler, Decoiler and Coil Car Roll Forming Machine Accesories from Roll Forming Machines LLC

Posted on Sunday, November 24, 2024

Contact us today with your specifications for a custom Uncoiler, Decoiler or Coil Car at [email protected] or call us at (+1) (407) 859 1119

Stud and Track Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Stud and Track Machine at [email protected] or call us at (+1) (407) 859 1119

Cee and Zee Purlin Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Cee and Zee Purlin Machine at [email protected] or call us at (+1) (407) 859 1119

Suspended Metal Ceiling Production Line

Posted on Wednesday, September 18, 2024

Suspended Metal Ceiling Profiles are structural components used to support and secure metal ceiling panels in a suspended ceiling system