Metal Roll Forming 101: Understanding the Basics and Beyond

Beyond its fundamental principles, metal roll forming is a gateway to innovation, efficiency, and versatility.

Posted on Monday, August 21, 2023

In the world of manufacturing and construction, precision and efficiency are paramount. One of the technological marvels that play a pivotal role in achieving these goals is metal roll forming. Whether you're new to the concept or looking to deepen your understanding, this guide will take you through the basics and explore the vast potential that metal roll forming holds.

The Basics of Metal Roll Forming

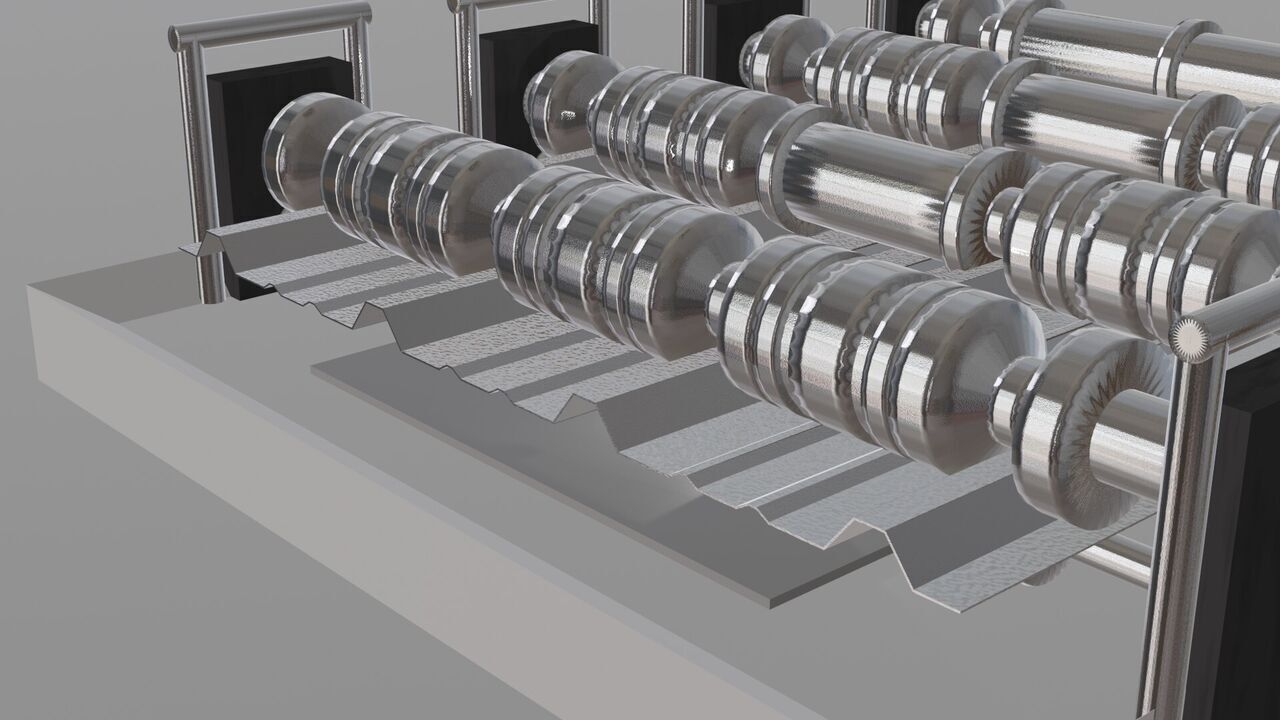

Metal roll forming is a manufacturing process that transforms metal coils or sheets into various complex shapes and profiles. This is achieved through carefully engineered rollers that progressively bend and shape the metal. The process begins with a flat metal sheet or coil being fed into the machine. As it passes through the series of rollers, it gradually takes on the desired shape.

How It Works

At its core, metal roll forming is about precision and control. The series of rollers are strategically designed to alter the shape of the metal gradually. Each roller performs a specific bending operation, contributing to the overall transformation. The complexity of the desired profile determines the number and arrangement of rollers.

Advantages of Metal Roll Forming

- Consistency: Metal roll forming is known for its exceptional consistency. The precision of the process ensures that each piece produced adheres to the same specifications, eliminating variations and defects.

- Cost Efficiency: The process minimizes material wastage, making it cost-effective in the long run.

- Additionally, the speed of production and reduced labor requirements contribute to overall cost savings.

- Complex Profiles: Metal roll forming can create profiles ranging from simple angles and channels to highly intricate designs. This versatility is a boon for industries that require diverse shapes.

- Material Options: The process is compatible with various metals, including steel, aluminum, copper, and more. This allows businesses to choose materials based on factors like strength, weight, and corrosion resistance.

Beyond the Basics: Exploring Applications

While the basics provide a solid foundation, the applications of metal roll forming extend far beyond simple profiles. Industries worldwide have harnessed this technology's power to innovate and transform the way they operate.

Automotive Industry

In the automotive sector, metal roll forming plays a crucial role in producing components like window frames, door panels, and roof rails. The ability to create precise shapes and maintain consistent quality aligns with the industry's high standards.

Construction and Architecture

Metal roll forming is a cornerstone of the construction and architecture industries. From structural components like beams and columns to decorative elements such as façade panels, the process offers the flexibility to cater to both functional and aesthetic requirements.

Furniture and Appliances

Even in seemingly unrelated domains, metal roll forming finds its place. Furniture manufacturers use it to craft durable, intricate designs, while the appliance industry relies on it to create parts that demand both form and function.

Green Energy Solutions

In the realm of renewable energy, metal roll forming contributes to the production of solar panel frames, wind turbine components, and other crucial parts. The precision and material efficiency of the process aligns well with the industry's sustainability goals.

Conclusion

Beyond its fundamental principles, metal roll forming is a gateway to innovation, efficiency, and versatility. This technology is at the heart of modern manufacturing and construction, from crafting complex profiles with precision to transforming entire industries. As businesses continue to evolve, the principles of metal roll forming remain constant, driving progress and setting new standards for excellence.

Suspended Metal Ceiling Production Line

Posted on Wednesday, September 18, 2024

Suspended Metal Ceiling Profiles are structural components used to support and secure metal ceiling panels in a suspended ceiling system

Posted on Wednesday, September 18, 2024

Galvalume drip edge is a protective strip made from Galvalume-coated steel, designed to be installed along the edges of roofs.

soffit panel roll forming machine

Posted on Wednesday, September 18, 2024

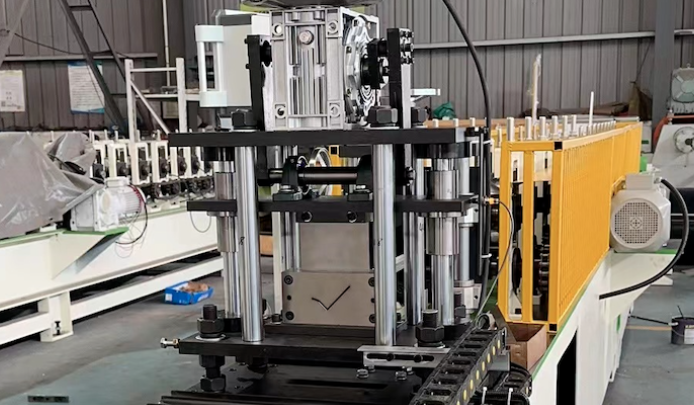

A soffit panel roll forming machine is designed to produce high-quality soffit panels used in roofing and siding systems.

Steel Overhead Garage Door Rolling Machine

Posted on Wednesday, September 18, 2024

A Steel Overhead Garage Door Rolling Machine is designed to manufacture rolling shutter doors, typically used for garages and industrial buildings.