Common Profiles for Roofing and Wall Panels

There are many panel profile options to choose from. Reviewing popular profile choices helps individuals better understand their strengths and weaknesses.

Posted on Friday, March 12, 2021

While lots of standing seam metal roofing profiles look quite similar, beneath the aesthetics, there are different features of each profile, making them quite unique. Most differences occur around the seams, which results in different ways that panels can be attached and other factors such as how well they will stand up against adverse weather.

Common types of roll and wall panels may look the same, but because of the way they have been produced, they may well have different warranties, slope requirements, testing requirements, and so on.

There are lots of different panel profile systems, details, and options to choose from. Reviewing the most popular profile choices help individuals better understand their strengths and weaknesses.

Let's take a look at some of them:

Panel type: Snap-lock

A snap-lock is a popular choice because it has been engineered to perform on a variety of roof deck assemblies. No seaming is required as the legs snap together after coming out of the roll forming machine. This makes it far less labor-intensive than other options. The installation is also faster than a mechanical lock, and the panel replacement is also straightforward.

Snap-locks tend to be weather-tight and will be covered by a warranty stating as much, making it a common choice for commercial applications. Snap-lock profiles are some of the most specified profiles in the metal roofing industry, regardless of what company's profile is used.

However, it is crucial to be aware that this profile cannot be used for low pitch roofs. They are not suitable for anything below 2/12. The aesthetic is also worth considering as the resulting look is more industrial, which may make them less appealing for residential property designs.

Mechanical Seam

Mechanical seams can be used on lower slopes, making them the standard choice for low pitch roofs.This seam type is also inexpensive in comparison to 2" mechanical profiles.This is due to the fact that less metal material is needed to complete the seam folds.

Snap-lock profiles can be viewed as bulkier than mechanical seams, which give a thinner result. They are also weather-tight and should be covered by a warranty. Mechanical seams are often used in residential applications as they provide a clean look, perform well, and are a cost-efficient option.

The drawbacks of this profile type are the installation time which is much more labor-intensive. The number of hours taken up installing may have a knock-on effect as to how cost-effective it really is. The panels are also harder to replace as they are mechanically sealed, which means repairing a single panel is challenging. It is also not a profile that is suitable for use on open framing applications.

Soffit Profile

The Soffit Profile doesn't require clips which means there are no additional costs. The panel is extremely versatile as it can be used as a panel on a wall or soffit. A roll forming machine can be programmed to produce this panel with perforations or without them. This profile is also tested and proven to stand up well even in severe weather conditions and is available for weather-tight warranties.

It is also possible to install it with a panel reveal, with a space between the panels or flush. However, the reveal is not engineered, and the weather-tight warranty will not cover it there. The installation is also quite labor-intensive because the panels must be screwed together.

The panel's width is also worth noting as they are smaller, which may have an adverse effect depending on where the wall is being erected. The seams must also lie perpendicular to the ground for the warranties to be valid, so the system must be installed vertically. However, if the warranty is not an issue, it is possible to install it horizontally too.

These profiles are just some of the types that can be created with metal roll forming machines. Remember, there is a wide variety of choices and advantages and disadvantages to each!

Suspended Metal Ceiling Production Line

Posted on Wednesday, September 18, 2024

Suspended Metal Ceiling Profiles are structural components used to support and secure metal ceiling panels in a suspended ceiling system

Posted on Wednesday, September 18, 2024

Galvalume drip edge is a protective strip made from Galvalume-coated steel, designed to be installed along the edges of roofs.

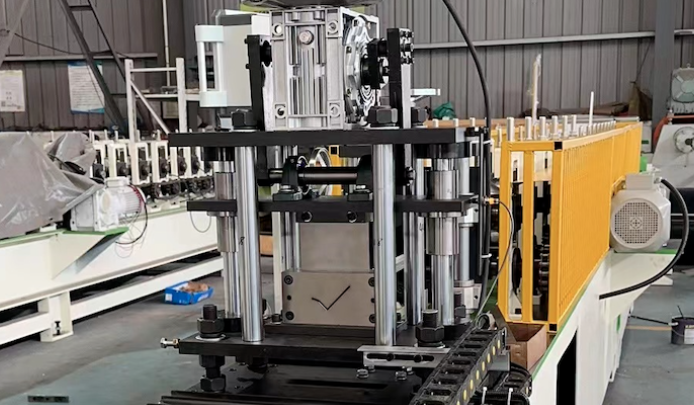

soffit panel roll forming machine

Posted on Wednesday, September 18, 2024

A soffit panel roll forming machine is designed to produce high-quality soffit panels used in roofing and siding systems.

Steel Overhead Garage Door Rolling Machine

Posted on Wednesday, September 18, 2024

A Steel Overhead Garage Door Rolling Machine is designed to manufacture rolling shutter doors, typically used for garages and industrial buildings.