What is the difference between stamping and roll forming?

Here's a brief overview of each process and their differences:

Posted on Tuesday, November 28, 2023

Stamping and roll forming are two different metal forming processes used in manufacturing to shape and manipulate sheet metal or other types of materials. While they both involve the deformation of metal, they have distinct differences in terms of their processes, applications, and end products. Here's a brief overview of each process and their differences:

- Stamping:

- Stamping is a metal forming process that involves the use of a press machine and a die to cut, bend, or shape sheet metal into the desired shape.

- It is often used for producing parts with complex shapes, such as automotive body panels, appliance components, and various metal brackets and connectors.

- Stamping typically starts with a flat sheet of metal, which is fed into the stamping press. The press exerts force on the metal sheet to create the desired shape by cutting and/or bending it.

- The die used in stamping is designed to have the negative shape of the final part, and the metal is forced into this die to take on that shape.

- Stamping is ideal for high-precision and high-volume production runs, where consistency and tight tolerances are crucial.

- Roll Forming:

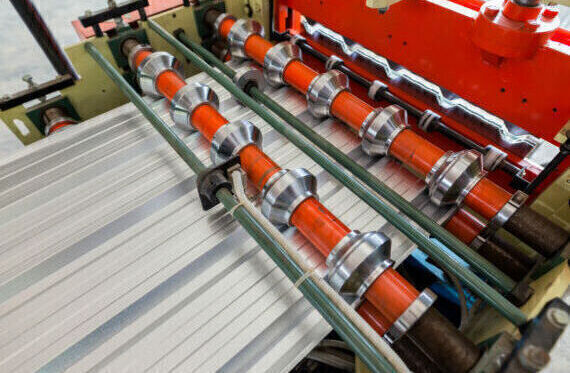

- Roll forming is a continuous metal forming process that involves passing a long strip or coil of sheet metal through a series of rolls (rollers) arranged in a specific sequence.

- It is often used to create long, uniform shapes with consistent cross-sections, such as channels, angles, tubes, and open profiles.

- In roll forming, the metal gradually takes on the desired shape as it passes through the series of rolls. Each roll performs a specific bending or shaping operation, incrementally forming the final profile.

- Roll forming is well-suited for producing long-length parts with consistent dimensions and is often used in the construction industry for producing building components like steel studs and roofing panels.

- While roll forming can be efficient for large production runs of parts with consistent cross-sections, it may not be suitable for producing parts with complex or irregular shapes.

In summary, stamping and roll forming are distinct metal forming processes that serve different purposes. Stamping is used for shaping sheet metal into complex and precise parts, often in high volumes, while roll forming is used to produce long-length parts with consistent cross-sections, typically in continuous production runs. The choice between these processes depends on the specific requirements of the part being manufactured.

Roll Forming Machines LLC's New Factory

Posted on Sunday, March 23, 2025

We have relocated factories, which will be available for tours very soon.

Uncoiler, Decoiler and Coil Car Roll Forming Machine Accesories from Roll Forming Machines LLC

Posted on Sunday, November 24, 2024

Contact us today with your specifications for a custom Uncoiler, Decoiler or Coil Car at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Stud and Track Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Stud and Track Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Cee and Zee Purlin Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Cee and Zee Purlin Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119