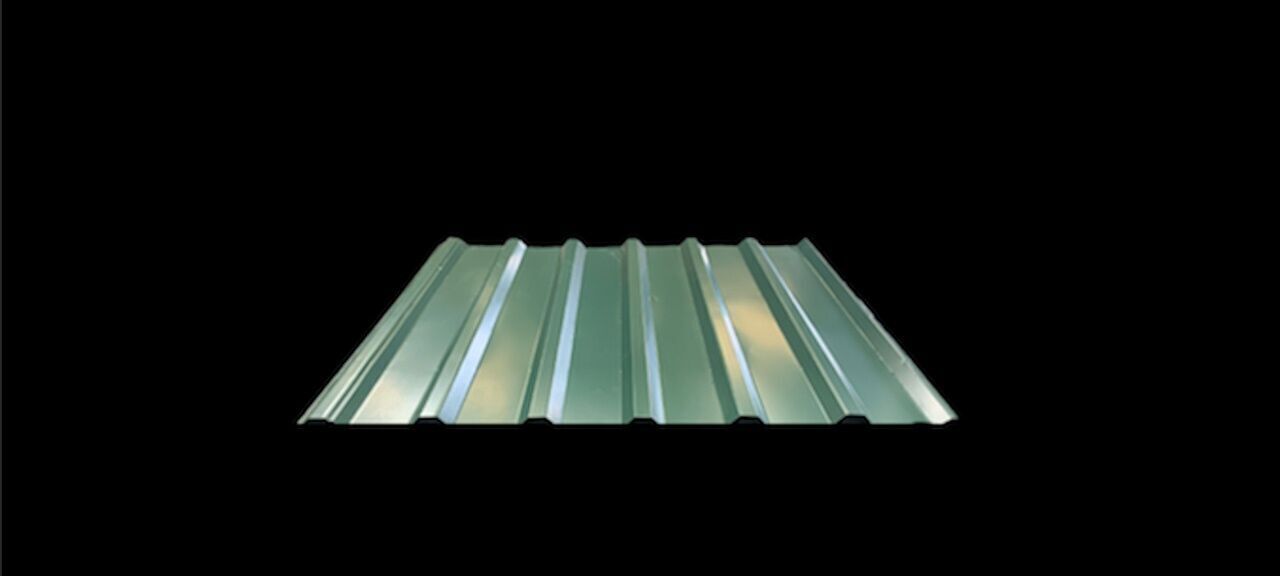

PBU Roof Panel

PBU roof panels may vary depending on the manufacturer and the particular product line.

Posted on Tuesday, November 21, 2023

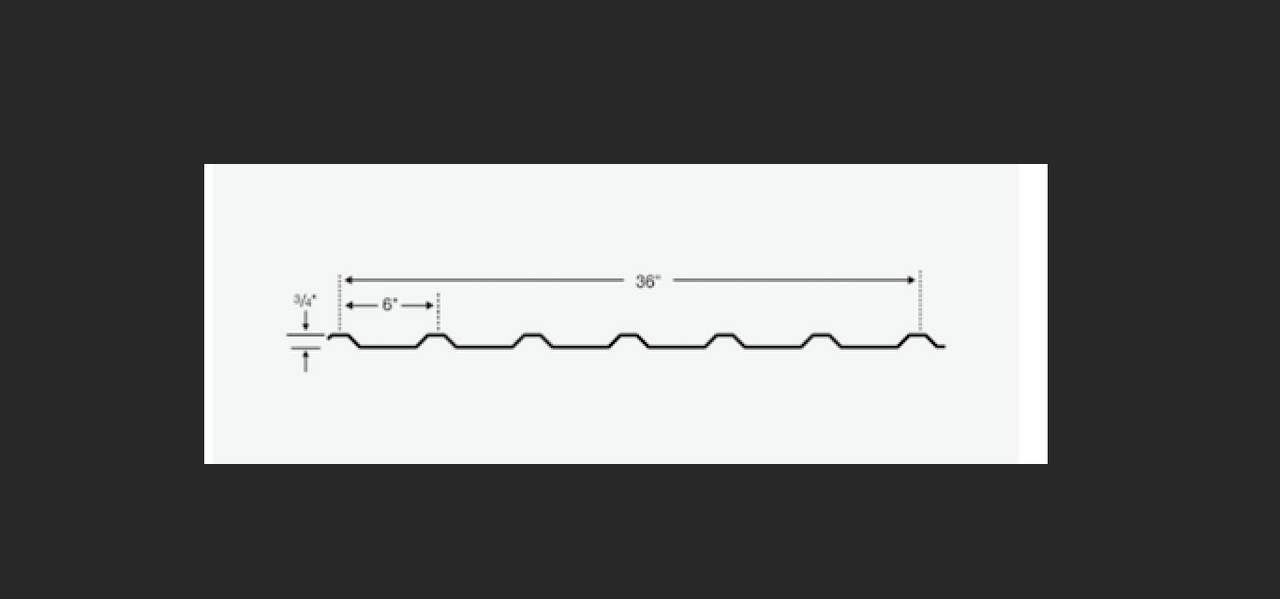

PBU Roof Panel Profile

PBU (standing for "Panel Batten U-Panel") is a type of metal roofing panel used in construction. PBU roof panels are designed for durability and are commonly used in commercial and industrial buildings. These panels are made from steel or other metal materials and offer several benefits for roofing applications:

- Durability: PBU roof panels are typically made from high-quality steel or metal alloys that are resistant to corrosion and weathering. This makes them a long-lasting roofing solution, capable of withstanding harsh environmental conditions.

- Easy Installation: PBU panels are often designed for easy installation, which can save time and labor costs during construction. They are typically available in various lengths, allowing for flexibility in design and installation.

- Energy Efficiency: Some PBU panels come with insulation options to enhance energy efficiency in buildings. Insulated panels can help regulate temperature and reduce heating and cooling costs.

- Weather Resistance: PBU roof panels are designed to provide protection against various weather elements, including rain, snow, hail, and strong winds. They often have a ribbed or corrugated profile that helps channel water away from the roof's surface.

- Low Maintenance: Once installed, PBU roof panels require minimal maintenance, which can save on long-term maintenance costs.

- Aesthetic Options: These panels come in a variety of colors and finishes, allowing for customization to match the aesthetics of the building.

- Sustainability: Some PBU panels are made from recyclable materials and can be recycled at the end of their life cycle, contributing to sustainability goals.

- Cost-Effective: PBU roof panels are often cost-effective when compared to other roofing materials, especially when considering their durability and low maintenance requirements.

It's important to note that the specific features and characteristics of PBU roof panels may vary depending on the manufacturer and the particular product line. Therefore, it's advisable to consult with a roofing professional or the manufacturer's documentation for detailed information about the PBU panels you intend to use in your construction project.

How is a PBU Roof Panel Made

The manufacturing process of PBU (Panel Batten U-Panel) roof panels typically involves several steps. While the exact process can vary depending on the manufacturer and the specific product line, here is a general overview of how PBU roof panels are made:

- Material Selection:

- The primary material used for PBU roof panels is steel, though other metal alloys may also be used. The steel is typically in the form of coils.

- Coil Unrolling:

- The steel coils are unrolled to the desired width for the panels. This process is often done using a machine called a decoiler.

- Roll Forming:

- The unrolled steel is passed through a series of roll-forming machines. These machines have sets of rollers that shape the flat steel into the desired corrugated or ribbed profile characteristic of PBU panels. The roll-forming process creates the panel's shape, including its raised seams and ribs.

- Cutting and Shearing:

- Once the steel has been roll-formed into the desired profile, it is cut to the appropriate lengths. Precision cutting and shearing equipment are used to achieve consistent panel sizes.

- Coating and Finishing:

- Some PBU panels receive a coating to enhance their durability and appearance. Common coatings include galvanized coatings (to protect against corrosion) and paint finishes (to provide color and additional protection).

- Embossing and Stamping (Optional):

- Depending on the design, some PBU panels may undergo embossing or stamping processes to add specific patterns or decorative elements to the panels.

- Insulation (Optional):

- If the PBU panels are designed to provide insulation for the building, this step involves adding an insulating material, such as foam or fiberglass, between the panels. Insulated PBU panels enhance the thermal performance of the roof.

- Packaging:

- The finished PBU panels are stacked, bundled, and packaged for shipment to construction sites or distribution centers.

It's important to note that the exact manufacturing process can vary between manufacturers and the specific product lines they offer. The quality and performance of PBU roof panels may also depend on the materials used, the manufacturing standards adhered to, and any additional features or coatings applied to the panels.

If you plan to use PBU roof panels for a construction project, it's advisable to consult with the manufacturer for detailed information about their specific manufacturing process, materials, and product specifications to ensure they meet your project's requirements.

PBU Roof Panel Size

manufacturer and the specific product line. However, I can provide you with some general information about common sizes and dimensions for PBU roof panels.

- Width:

- The width of PBU roof panels typically ranges from 24 inches to 36 inches (approximately 61 cm to 91 cm). The choice of width may depend on factors such as the building's design, structural considerations, and the manufacturer's offerings.

- Length:

- PBU roof panels are often manufactured in custom lengths to suit the specific needs of a building project. Standard lengths can range from 6 feet to 40 feet (approximately 1.8 meters to 12 meters) or even longer. Custom lengths can be ordered to minimize waste and ensure a proper fit for the roof.

- Thickness:

- The thickness of PBU roof panels can vary depending on the gauge of the steel used. Common thicknesses for PBU panels range from 26 to 24 gauge, with 26-gauge panels being thinner than 24-gauge panels. Thicker panels may offer increased durability and load-bearing capacity.

- Rib Height and Spacing:

- PBU panels have a distinctive ribbed or corrugated profile. The height and spacing of the ribs can also vary between different manufacturers and product lines. Common rib heights range from 1 inch to 2.67 inches (approximately 2.54 cm to 6.76 cm), and rib spacing can vary from 6 to 12 inches (approximately 15.24 cm to 30.48 cm).

It's important to note that these dimensions are general guidelines, and the specific size options available may vary from one manufacturer to another. Additionally, the choice of PBU panel size should be based on the structural requirements of your building, local building codes, and the design specifications of your roofing project.

When selecting PBU roof panels for a construction project, it's recommended to work with a roofing professional or contact the manufacturer directly to determine the available size options and choose the one that best fits your project's needs. Custom sizing may also be an option to ensure a precise fit for your roofing project.

View all are Roof panel roll forming machines here

Roll Forming Machines LLC's New Factory

Posted on Sunday, March 23, 2025

We have relocated factories, which will be available for tours very soon.

Uncoiler, Decoiler and Coil Car Roll Forming Machine Accesories from Roll Forming Machines LLC

Posted on Sunday, November 24, 2024

Contact us today with your specifications for a custom Uncoiler, Decoiler or Coil Car at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Stud and Track Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Stud and Track Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Cee and Zee Purlin Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Cee and Zee Purlin Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119