Corrugated Metal Roof Panels

Here are some key features and advantages of corrugated metal roof panels:

Posted on Wednesday, November 22, 2023

Corrugated Metal Roof Panels

Corrugated metal roof panels are a popular roofing material known for their durability, strength, and cost-effectiveness. They are made from sheets of metal, typically steel or aluminum, that have been formed into a wavy or corrugated pattern. This pattern not only adds structural integrity to the panels but also helps to channel water and prevent water buildup on the roof.

Here are some key features and advantages of corrugated metal roof panels:

- Durability: Corrugated metal roof panels are highly durable and can withstand a wide range of weather conditions, including heavy rain, snow, hail, and strong winds. They are also resistant to fire, insects, and rot, making them a long-lasting roofing option.

- Lightweight: Despite their durability, corrugated metal panels are relatively lightweight, which can simplify the installation process and reduce the load on the building's structure.

- Cost-effective: Corrugated metal roofing is often more cost-effective than other roofing materials, both in terms of initial installation costs and long-term maintenance. It requires minimal maintenance and is known for its longevity.

- Energy efficiency: Reflective coatings can be applied to corrugated metal roof panels to enhance their energy efficiency by reducing heat absorption. This can help keep the building cooler in hot weather, potentially reducing cooling costs.

- Environmentally friendly: Metal roofing materials are recyclable, which makes them an environmentally friendly choice. They can often be recycled at the end of their lifespan, reducing the environmental impact.

- Versatility: Corrugated metal panels are available in a variety of colors and finishes, allowing for customization to match the aesthetic of your building. They can be used on residential, commercial, agricultural, and industrial structures.

- Easy installation: Corrugated metal roof panels are relatively easy to install, especially when compared to some other roofing materials. However, it's important to have them installed by experienced professionals to ensure proper sealing and waterproofing.

- Water shedding: The corrugated pattern on these panels helps water to flow off the roof quickly, reducing the risk of water pooling or leakage.

- Longevity: Corrugated metal roofs can last for several decades with proper maintenance, often outlasting other roofing materials.

- Resistance to pests: Metal roofing is not susceptible to damage from pests like termites, which can be a problem with some other roofing materials.

While corrugated metal roof panels have many advantages, it's essential to consider your specific needs, budget, and local climate when choosing a roofing material. Additionally, proper installation and maintenance are crucial for ensuring the longevity and performance of your metal roof. Consulting with a roofing professional is often a wise step in making an informed decision about your roofing material choice.

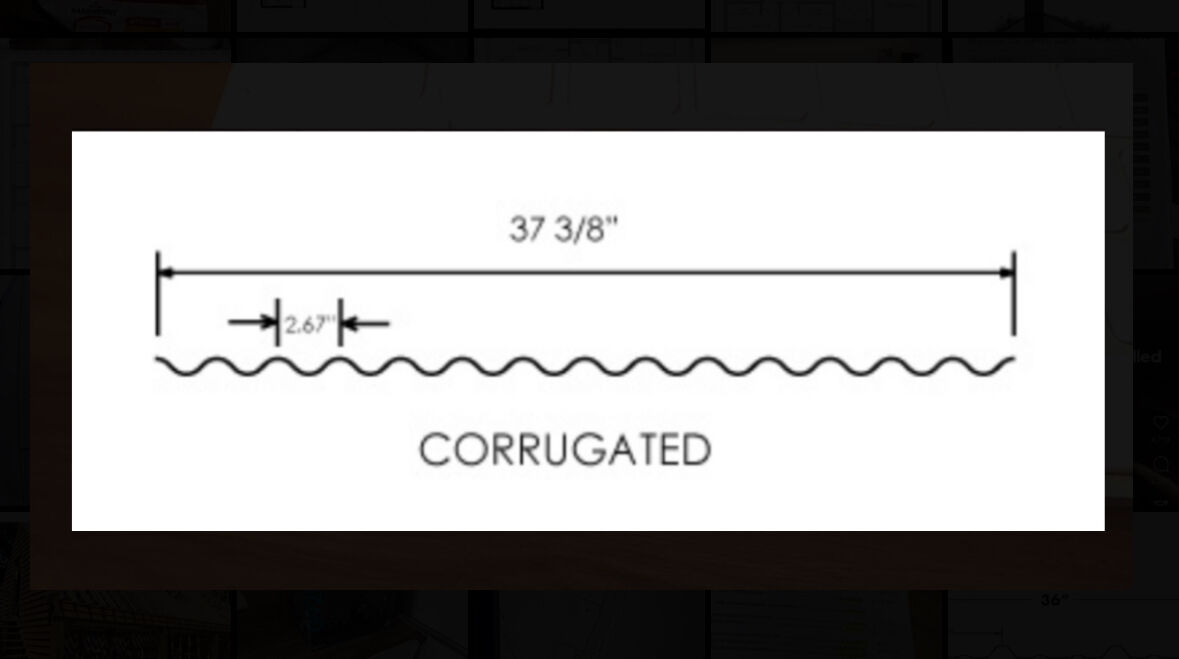

Corrugated metal roof panels sizes

Corrugated metal roof panels come in various sizes to accommodate different roofing projects and preferences. The most common sizes for corrugated metal roof panels include:

- Width: The width of corrugated metal roof panels can vary, but a common width range is between 26 inches and 42 inches. Wider panels are often used for larger buildings, while narrower panels may be suitable for smaller structures.

- Length: The length of corrugated metal panels is typically customized to fit the specific dimensions of the roof. Common lengths range from 6 feet to 12 feet or more. Custom lengths can be ordered to minimize waste and ensure a proper fit for your project.

- Thickness (Gauge): The thickness of corrugated metal roof panels is usually specified in terms of gauge. The gauge indicates the thickness of the metal, with lower gauge numbers representing thicker panels. Common gauge options for corrugated metal roofing include 26-gauge, 24-gauge, and 22-gauge. Thicker gauges offer increased durability and resistance to damage but may be more expensive.

- Rib Spacing: Corrugated metal panels have a series of ridges or corrugations that run along their length. The spacing between these ribs can vary, affecting the panel's appearance and structural integrity. Typical rib spacings are 2.5 inches and 4 inches, but other spacings may also be available.

- Profile: Corrugated metal roof panels are available in different profiles, with varying heights and shapes of the corrugations. The most common profile is the classic "sinusoidal" or "wave" shape, but some profiles may have deeper or shallower corrugations for specific design preferences or functional requirements.

- Coating and Finish: Corrugated metal roof panels can have various coatings and finishes to enhance their performance and appearance. These may include galvanized coatings, paint finishes, and reflective coatings to improve energy efficiency.

It's important to note that the availability of sizes and options can vary depending on the manufacturer and supplier. When planning a roofing project, it's advisable to consult with roofing professionals or suppliers to determine the most suitable panel sizes, thicknesses, and other specifications for your specific needs. They can help you choose the right corrugated metal roof panels to ensure the success and longevity of your roofing project.

Corrugated metal roof panels pricing

The pricing of corrugated metal roof panels can vary widely depending on several factors, including the material, gauge, finish, size, and the region where you are purchasing them. Additionally, labor costs for installation, as well as any additional materials and accessories needed for the roofing project, will influence the overall cost. Here are some key factors that can impact the pricing of corrugated metal roof panels:

- Material: Corrugated metal roof panels can be made from different materials, with steel and aluminum being the most common choices. Steel panels are generally more affordable than aluminum ones, but aluminum is lighter and more corrosion-resistant.

- Gauge: The thickness of the metal panels, often measured in gauges, affects the price. Thicker gauges are more expensive but offer greater durability.

- Finish: The type of coating or finish applied to the panels can affect the cost. Galvanized coatings, paint finishes, and special coatings for energy efficiency can add to the price.

- Size: The size of the panels, including width, length, and rib spacing, will impact the cost. Custom sizes may be more expensive than standard sizes due to the need for customization.

- Quantity: Bulk purchases of corrugated metal roof panels may lead to discounts or lower unit prices. Buying in larger quantities can often reduce the overall cost per panel.

- Supplier: Prices can vary between different suppliers and manufacturers. It's a good idea to obtain quotes from multiple suppliers to compare prices and choose the most competitive option.

- Location: Regional factors such as shipping costs, local labor rates, and demand for roofing materials can influence pricing. Prices may be higher in areas with high construction demand or limited access to suppliers.

- Installation: Labor costs for the installation of corrugated metal roof panels can be a significant portion of the overall project cost. Labor rates can vary widely depending on the location and complexity of the installation.

- Additional Materials and Accessories: You may need additional materials such as fasteners, underlayment, flashing, and trim to complete the roofing project. These costs should also be factored into your budget.

To get an accurate estimate for your specific project, it's recommended to obtain quotes from local suppliers and contractors. They can provide you with pricing based on your unique requirements and location. Additionally, consider the long-term benefits of investing in a durable roofing material like corrugated metal, as it can provide cost savings over the life of the roof due to its longevity and low maintenance requirements.

View all are Roof panel roll forming machines here

Roll Forming Machines LLC's New Factory

Posted on Sunday, March 23, 2025

We have relocated factories, which will be available for tours very soon.

Uncoiler, Decoiler and Coil Car Roll Forming Machine Accesories from Roll Forming Machines LLC

Posted on Sunday, November 24, 2024

Contact us today with your specifications for a custom Uncoiler, Decoiler or Coil Car at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Stud and Track Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Stud and Track Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Cee and Zee Purlin Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Cee and Zee Purlin Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119