PBR Roof Panel

PBR stands for "Purlin Bearing Rib," which describes one of its key features.

Posted on Tuesday, October 10, 2023

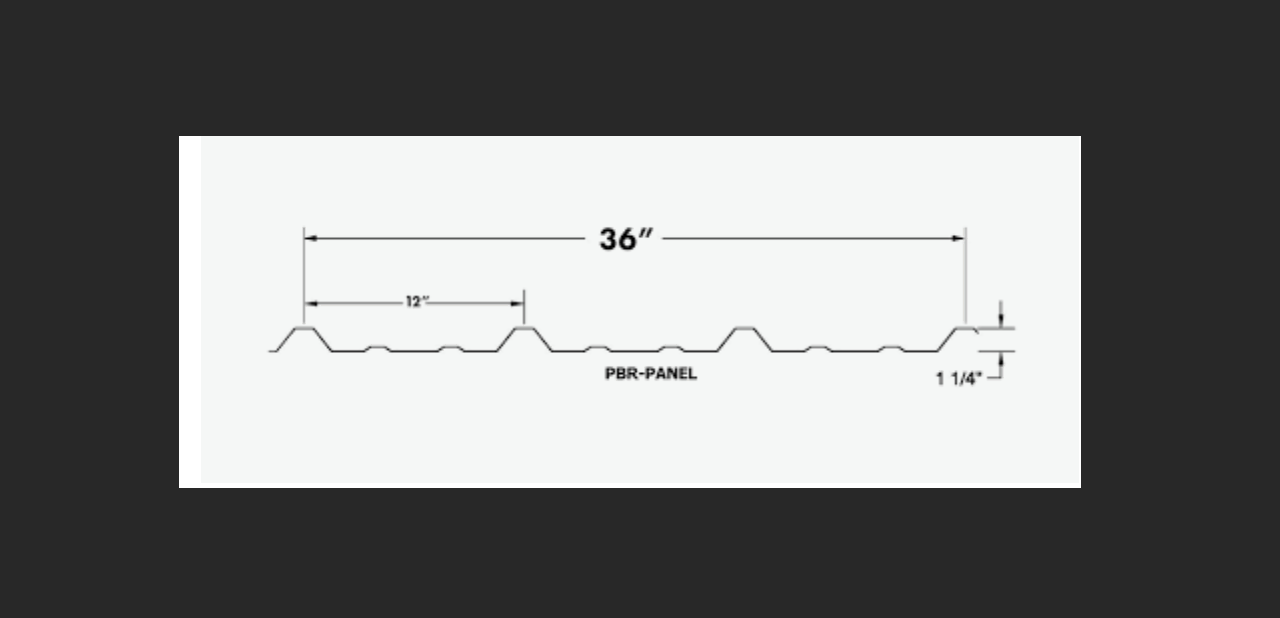

PBR Roof Panel Profile

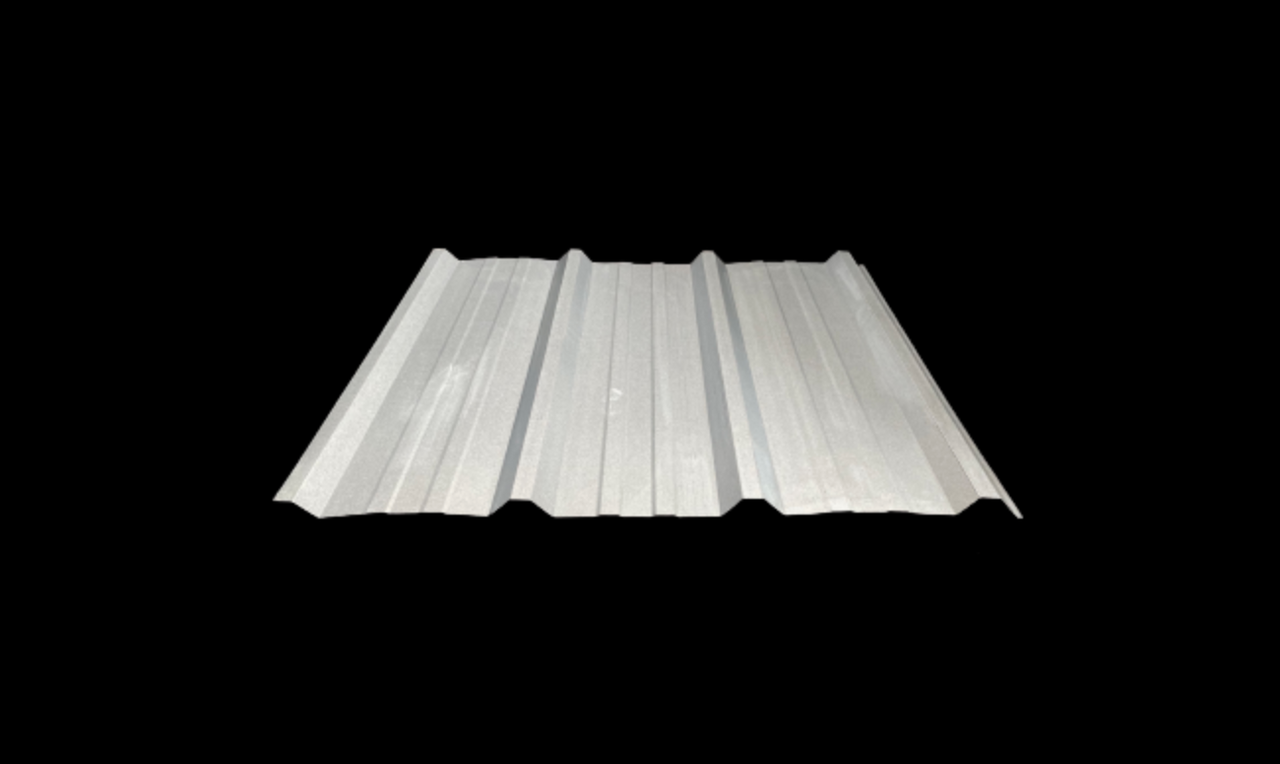

PBR Roof Panel, often referred to as "PBR Panel," is a type of metal roofing panel commonly used in commercial and industrial building construction. PBR stands for "Purlin Bearing Rib," which describes one of its key features. Here are some characteristics and information about PBR Roof Panels:

- Ribbed Design: PBR Panels have a distinctive ribbed profile with high ribs and wide valleys. The high ribs provide strength and stability to the panel, making it suitable for spanning long distances without the need for excessive support structures.

- Purlin Bearing: The term "Purlin Bearing Rib" signifies that PBR Panels are designed to rest on and be fastened to purlins or structural support members. This feature simplifies installation and enhances the panel's structural integrity.

- Metal Material: PBR Roof Panels are typically made from metal materials such as steel or aluminum. These materials are chosen for their durability, longevity, and resistance to weathering.

- Coatings: To protect against corrosion and enhance aesthetics, PBR Panels are often coated with various finishes or coatings. Common coatings include galvanized, galvalume, or painted finishes.

- Sizes and Profiles: PBR Panels come in various sizes and profiles, allowing for flexibility in design and application. The specific dimensions and profiles can vary by manufacturer and project requirements.

- Installation: PBR Panels are relatively easy to install, and their design allows for quick and efficient installation. They are typically installed horizontally, starting from the eave and progressing towards the ridge of the roof.

- Applications: PBR Roof Panels are commonly used in industrial and commercial roofing applications, including warehouses, factories, agricultural buildings, and retail spaces. They are chosen for their strength, durability, and cost-effectiveness.

- Weather Resistance: PBR Panels are known for their ability to withstand harsh weather conditions, including wind, rain, snow, and hail. They provide excellent protection against the elements.

- Insulation: PBR Panels can be used in conjunction with insulation materials to improve energy efficiency and thermal performance in buildings.

- Longevity: Properly installed and maintained PBR Roof Panels can have a long service life, often lasting several decades.

It's important to note that the specific details and characteristics of PBR Roof Panels may vary based on the manufacturer and the project's requirements. When considering PBR Panels for a roofing project, it's advisable to consult with roofing professionals and manufacturers to ensure that you select the appropriate panel type and specifications for your specific needs.

PBR roof panel dimensions

The dimensions of PBR (Purlin Bearing Rib) Roof Panels can vary depending on the manufacturer and the specific project requirements. However, I can provide you with some common dimensions that you might encounter for PBR Roof Panels. Please note that these dimensions are general guidelines, and actual sizes may vary:

- Length: PBR Roof Panels are typically available in various lengths, with common options ranging from 6 feet to 40 feet or more. The choice of panel length depends on the building's dimensions and the desired roof coverage.

- Width: The width of PBR Panels is usually between 24 inches and 36 inches. Again, the exact width may vary by manufacturer and project specifications.

- Thickness: The thickness of PBR Roof Panels can vary, but common thicknesses include 24 gauge (0.024-inch thickness) and 26 gauge (0.0185-inch thickness) for steel panels. Thicker or thinner options may also be available depending on your needs.

- Rib Height: The height of the high ribs on a PBR Roof Panel can vary, but it's typically in the range of 1.25 inches to 1.5 inches. The height of the ribs contributes to the panel's strength and structural integrity.

- Rib Spacing: The spacing between the high ribs is typically uniform and can range from 12 inches to 16 inches, depending on the manufacturer and design specifications.

- Valley Width: The width of the valleys or troughs between the high ribs can also vary, but it is usually wide enough to facilitate efficient water drainage from the roof's surface.

- Overlap: During installation, PBR Panels are often overlapped at their edges to create a weather-tight seal. The amount of overlap may vary, but it's typically around 4 to 6 inches.

It's important to note that these dimensions are general guidelines, and the specific dimensions of PBR Roof Panels can vary based on the manufacturer's product offerings and customization options. When planning a roofing project, it's essential to consult with the manufacturer or supplier to determine the exact dimensions and specifications that will best meet your project's requirements. Additionally, building codes and local regulations may influence the choice of panel dimensions and thickness to ensure the structural integrity of the roofing system.

How are PBR roof panels made

PBR (Purlin Bearing Rib) roof panels are typically made using a manufacturing process that involves several steps. The exact process may vary depending on the manufacturer and the specific material used (commonly steel or aluminum), but the following is a general overview of how PBR roof panels are typically made:

- Material Selection: The process begins with the selection of the raw material, which is usually rolls of steel or aluminum coil. The material is chosen for its durability, strength, and corrosion resistance.

- Coil Uncoiling: The rolls of coil are uncoiled and fed into the manufacturing line. The material is typically cleaned and treated to remove any contaminants and prepare it for the forming process.

- Roll Forming: Roll forming is the primary manufacturing method for creating the shape and profile of the PBR panels. In this step, the material passes through a series of rollers and dies that gradually shape it into the desired profile, including the high ribs, valleys, and any other features specific to the panel design.

- Cut-to-Length: After roll forming, the continuous panel is cut into individual lengths according to the specified dimensions. The cut lengths will become the finished PBR roof panels.

- Rib and Edge Detailing: Additional manufacturing steps may include adding any required edge details or special features to the panels. For example, some panels may have snap-on seam caps or other accessories that are attached during this stage.

- Coating Application: To protect the panels from corrosion and enhance their appearance, various coatings and finishes are applied. Common coatings include galvanized coatings, galvalume coatings, or paint finishes. The coating process may involve dipping, spraying, or other methods, depending on the chosen finish.

- Curing and Cooling: If a coating or finish requires curing, the panels are typically passed through an oven or other curing equipment to ensure the coating adheres properly. Afterward, the panels are cooled to room temperature.

- Quality Control: Throughout the manufacturing process, quality control checks are performed to ensure that the panels meet the specified standards for dimensions, profile, coating thickness, and overall quality.

- Packaging and Shipping: Once the PBR roof panels have passed quality control, they are usually bundled, packaged, and prepared for shipping to construction sites, distributors, or customers.

It's important to note that some manufacturers may incorporate additional steps or variations in the process to create customized PBR panels with unique features, coatings, or specifications. The quality of the manufacturing process is crucial to producing durable and reliable roofing panels that can withstand the elements and provide long-lasting protection for buildings.

View all are Roof panel roll forming machines here

Roll Forming Machines LLC's New Factory

Posted on Sunday, March 23, 2025

We have relocated factories, which will be available for tours very soon.

Uncoiler, Decoiler and Coil Car Roll Forming Machine Accesories from Roll Forming Machines LLC

Posted on Sunday, November 24, 2024

Contact us today with your specifications for a custom Uncoiler, Decoiler or Coil Car at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Stud and Track Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Stud and Track Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Cee and Zee Purlin Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Cee and Zee Purlin Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119