Drip Edge Flashing

Here are some key functions and benefits of drip edge flashing:

Posted on Friday, October 20, 2023

Drip Edge Flashing

Drip edge flashing is a critical component of a roofing system designed to protect the edges of a roof from water damage. It is typically made of metal, such as aluminum or galvanized steel, and is installed along the edges of the roof, both along the eaves (the horizontal edge) and the rakes (the sloped edges).

Here are some key functions and benefits of drip edge flashing:

- Water Diversion: Drip edge flashing helps direct water away from the roof edge and into the gutter system. Without it, water can seep under the roofing materials, causing damage to the roof deck and potentially leading to leaks inside the building.

- Prevents Rot and Decay: By preventing water from accumulating at the roof edge, drip edge flashing helps protect the underlying wood or other roofing materials from rot, decay, and deterioration over time.

- Pest Prevention: It also acts as a barrier against insects and small animals that might try to access the roof or attic space from the roof edge.

- Aesthetic Finish: Drip edge flashing provides a finished, clean look to the roof's edges and can improve the overall appearance of the roofing system.

- Wind Resistance: In areas prone to high winds, drip edge flashing can help anchor the roofing materials in place, reducing the risk of wind-driven rain and debris getting under the roof.

Installation of drip edge flashing typically involves placing it under the roofing material (such as shingles) along the eaves and over the roofing material along the rakes. Proper installation is crucial to ensure that water is effectively directed away from the roof edge.

Drip edge flashing is an essential component of a well-designed roofing system, and its installation should be done carefully to provide long-term protection against water damage and other potential issues. It's important to follow local building codes and manufacturer guidelines when installing drip edge flashing to ensure it is installed correctly and serves its intended purpose.

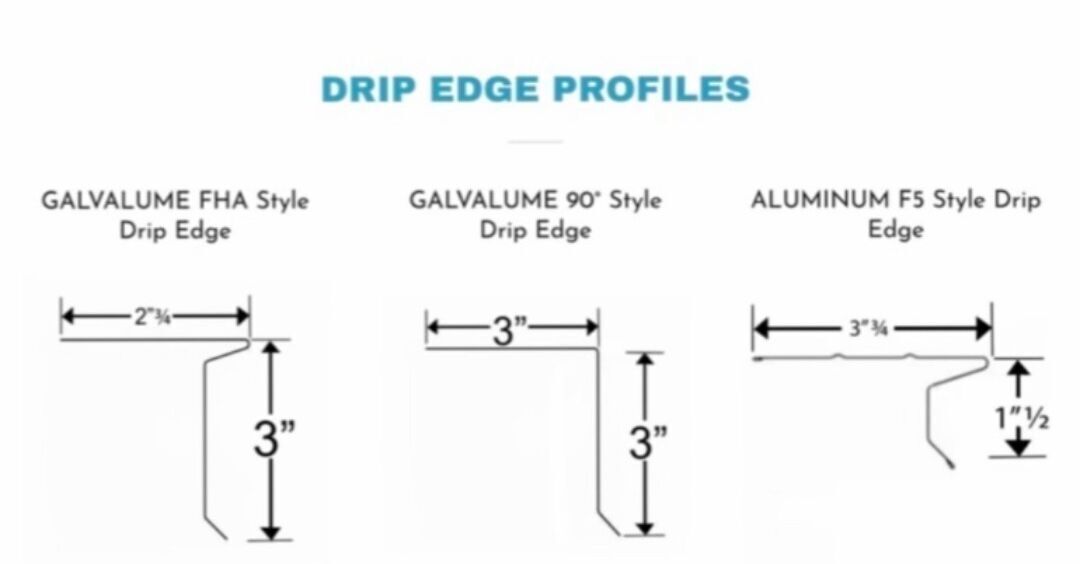

Types of drip edge flashings

There are several types of drip edge flashings available, each designed for specific applications and roofing systems. The choice of drip edge flashing depends on factors like the roofing material, climate, and local building codes. Here are some common types of drip edge flashings:

- L-Shaped Drip Edge Flashing:

- L-shaped drip edge flashing is the most common type and is used for asphalt shingle roofs, metal roofs, and other roofing materials. It has an L-shaped profile with one leg that goes under the roofing material and another that extends out and over the roof edge to direct water away from the structure.

- T-Shaped Drip Edge Flashing:

- T-shaped drip edge flashing is similar to L-shaped flashing but has an additional horizontal extension that provides extra protection along the roof edge. It is often used in areas with heavy rainfall or ice dams to prevent water from getting under the roofing materials.

- Hemmed Drip Edge Flashing:

- Hemmed drip edge flashing has folded or rolled edges, providing additional strength and rigidity. This type of flashing is commonly used in areas prone to strong winds and for commercial roofing systems.

- Drip Edge with Built-In Fascia:

- Some drip edge flashings come with a built-in fascia, providing a clean and finished look to the roof's edge. This type of flashing is often used with metal roofing systems.

- Vinyl Drip Edge Flashing:

- Vinyl drip edge flashing is an alternative to metal flashing and is typically used for vinyl siding and other exterior cladding systems. It is lightweight, corrosion-resistant, and easy to install.

- Copper Drip Edge Flashing:

- Copper drip edge flashing is a premium option known for its durability and attractive appearance. It is commonly used in high-end roofing applications and can develop a natural patina over time.

- Gutter Apron:

- Gutter apron is a type of drip edge flashing specifically designed to work in conjunction with gutters. It extends over the gutter's top edge and helps direct water directly into the gutter while preventing water from getting behind it.

- Ice and Water Barrier Drip Edge:

- This type of drip edge flashing is designed to provide additional protection against ice dams and water infiltration. It incorporates an ice and water barrier membrane that adheres to the roof deck, offering added leak prevention in areas with cold climates.

- Retrofit Drip Edge:

- Retrofit drip edge flashing is used when replacing an existing roof, allowing for the installation of drip edge without removing the old roofing materials.

The choice of drip edge flashing should be based on the specific requirements of your roofing system and local building codes. Proper installation is crucial to ensure that the flashing effectively directs water away from the roof edge and prevents damage to the underlying structure.

Roll Forming Machines LLC's New Factory

Posted on Sunday, March 23, 2025

We have relocated factories, which will be available for tours very soon.

Uncoiler, Decoiler and Coil Car Roll Forming Machine Accesories from Roll Forming Machines LLC

Posted on Sunday, November 24, 2024

Contact us today with your specifications for a custom Uncoiler, Decoiler or Coil Car at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Stud and Track Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Stud and Track Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Cee and Zee Purlin Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Cee and Zee Purlin Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119