Innovative and Efficient: The Evolution of Servo-Driven Metal Roll Forming Machines

Servo-driven metal roll forming machines offer several advantages over traditional mechanically driven machines

Posted on Tuesday, September 26, 2023

Metal roll-forming machines have been around for many years, but they have evolved significantly in recent years, largely thanks to the introduction of servo-driven systems.

How servo-driven metal roll-forming machines work

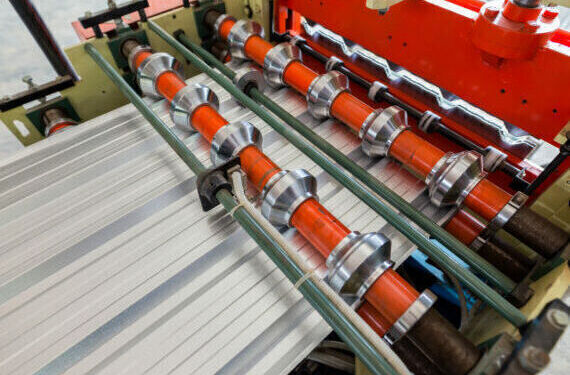

Servo-driven metal roll-forming machines pass a continuous strip of metal through a series of rollers. The rollers are arranged in a specific sequence to bend and shape the metal into the desired profile progressively. The servo motors control the position and speed of the rollers to ensure that the metal is formed to precise specifications.

Servo-driven metal roll forming machines offer several advantages over traditional mechanically driven machines, including:

- Increased precision: Servo-driven machines can achieve higher precision and accuracy than mechanically driven machines. This is because servo motors can be controlled with greater precision.

- Increased production rates: Servo-driven machines can operate faster than mechanically driven machines. This is because servo motors can provide more torque and acceleration.

- Reduced energy consumption: Servo-driven machines are more energy-efficient than mechanically driven machines. This is because servo motors can operate at variable speeds and can be turned off when not needed.

- Reduced noise levels: Servo-driven machines are quieter than mechanically driven machines. This is because servo motors do not produce the same noise as mechanical components.

- Easier to operate: Servo-driven machines are easier to operate and maintain than mechanically driven machines. This is because servo systems are more sophisticated and can be programmed to perform complex tasks.

Applications of servo-driven metal roll-forming machines

Servo-driven metal roll-forming machines are used in a wide range of industries, including:

- Construction: Servo-driven metal roll-forming machines produce a range of metal building materials, such as roof panels, wall panels, and framing members.

- Automotive: Servo-driven metal roll-forming machines produce a variety of automotive components, such as chassis rails, body panels, and exhaust systems.

- Aerospace: Servo-driven metal roll-forming machines create many aerospace components, such as aircraft wings, fuselage panels, and engine parts.

- Manufacturing: Servo-driven metal roll-forming machines help to make a wide variety of manufactured goods, such as appliances, electronics, and machinery.

The future of servo-driven metal roll-forming machines

The future of servo-driven metal roll-forming machines is positive. As technology evolves, servo-driven devices will become even more precise, efficient, and versatile. This will make them even more attractive to a wide range of industries.

Here are some of the trends that are shaping the future of servo-driven metal roll-forming machines:

- Increased use of artificial intelligence (AI): AI may be used to develop new and innovative servo control systems that can further improve precision and efficiency.

- Increased use of the Internet of Things (IoT): The IoT is being used to connect servo-driven machines to networks, which allows for remote monitoring and control. This can improve productivity and reduce downtime.

- Development of new materials and processes: New materials and techniques are in development, and these will allow servo-driven machines to produce a broader range of products.

Conclusion

Servo-driven metal roll-forming machines are the future of metal roll-forming. They offer several advantages over traditional mechanically driven machines, including increased precision, faster production rates, reduced energy consumption, reduced noise levels, and more straightforward operation.

If you are looking for a metal roll-forming machine that can help you improve your productivity and quality, then a servo-driven machine is the right choice. Browse the range from roll forming LLC or contact our friendly team today to see how they can help.

Roll Forming Machines LLC's New Factory

Posted on Sunday, March 23, 2025

We have relocated factories, which will be available for tours very soon.

Uncoiler, Decoiler and Coil Car Roll Forming Machine Accesories from Roll Forming Machines LLC

Posted on Sunday, November 24, 2024

Contact us today with your specifications for a custom Uncoiler, Decoiler or Coil Car at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Stud and Track Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Stud and Track Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Cee and Zee Purlin Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Cee and Zee Purlin Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119