Custom roll forming

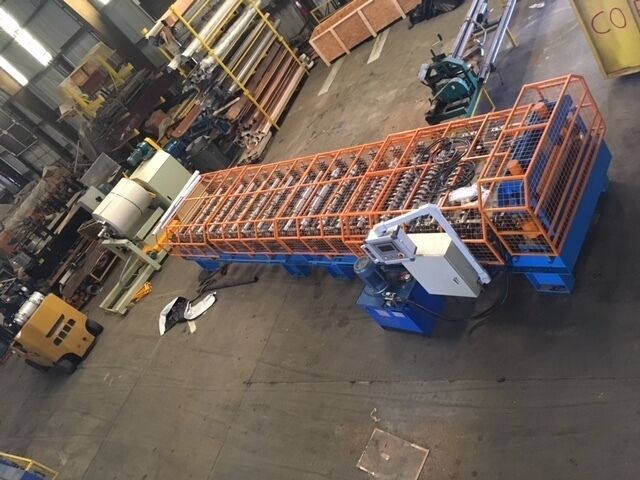

Roll forming machines can help businesses that need to manipulate sheet metal to make parts for their products.

Posted on Thursday, July 29, 2021

Of course, there are many companies that require metal parts to make what they sell, and that’s why roll formers are used across a massive number of industries.

However, with the boom in technology and product production over the years, the need for more complicated, intricate parts for products is ever increasing. This means that the demand for roll forming machines that don’t work to a ‘one size fits all’ specification is more prevalent than ever.

Because of technological advances, many modern roll forming machines are now equipped with in-built computers. These can be programmed with exact specifications to ensure that the sheet metal is manipulated precisely and that the end products are uniform and accurate.

Custom roll forming - what exactly is it?

Custom Roll Forming is the process of manipulating strip metal by feeding it into the roll forming machine. The machine contains several specially designed rolls, which then bend and shape the metal accordingly. With decades of knowledge and expertise to offer, the customer team at Rollforming LLC is perfectly positioned to help advise and assist our customers by providing tailored solutions to meet almost any custom roll forming needs.

Custom roll forming - the advantages

The roll forming process is an awe-inspiring one. By using a roll forming in your businesss, you can easily and efficiently manufacture common shaped sections, such as Channel, Angle, Boxes or Round tubes. However, thanks to customer roll forming, contemporary roll forming machines now also have the ability to produce more complex profiles that match the ever-increasing demand for technical solutions.

This unique ability to create complex shapes from sheet metal also provides designers and those working to develop a range of manufacturing options to create a vast number of designs on top of the more traditional type processes, such as press or press braking, create a product.

The Custom Roll Forming process involves providing bespoke, uniquely crafted standard metal profiles and special welded tubes in a range of thicknesses. These custom-made profiles can be fabricated from a number of different metals, including steel, stainless steel, copper, aluminum, brass, and even pre-painted material.

An additional advantage of employing a custom roll forming machine is that there is less stress applied to the metal. If metal is bent with force at great speed, this could weaken the structure. However, the process that the sheet metal goes through in a custom roll former is much more controlled, meaning the end result will be to the exact programmed specifications devoid of any inherent weaknesses that could be caused by stress to the material. The gradual, continual forming process and intelligent design of these custom roll forming machines result in an innovative, durable, high-quality end product that can be mass-produced to exact specifications.

Inventive, intelligent custom roll forming is designed to be flexible and adaptable without losing any precision. If you are searching for a top-quality roll forming machine for your business, browse our range or contact our experienced customer team, who will be delighted to help you.

Roll Forming Machines LLC's New Factory

Posted on Sunday, March 23, 2025

We have relocated factories, which will be available for tours very soon.

Uncoiler, Decoiler and Coil Car Roll Forming Machine Accesories from Roll Forming Machines LLC

Posted on Sunday, November 24, 2024

Contact us today with your specifications for a custom Uncoiler, Decoiler or Coil Car at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Stud and Track Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Stud and Track Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Cee and Zee Purlin Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Cee and Zee Purlin Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119