What is the Roll Forming Process?

Find out how the roll forming process works.

Posted on Friday, January 17, 2020

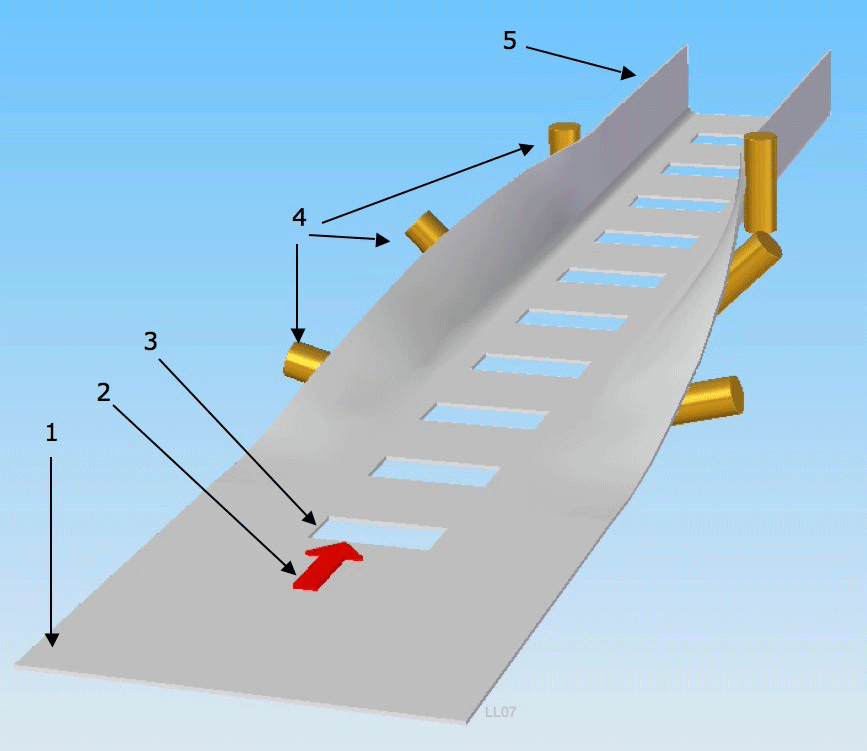

The roll forming process (also spelled rollforming and roll-forming) is a process in which sheet metal is passed through a series of rollers on a roll forming machine to alter its shape, creating a uniform cross-section. Roll forming can be used to process large quantities and long lengths of sheet metal continuously.

Application Of Rolling Process

Roll forming machines are used to create many products that are used in industry and in daily life. A few of the products made via roll forming are garage doors, automobile panels, metal roof panels, metal roofing tiles, roof ridges, metal wall panels or cladding, siding panels, and metal decking for a floor or roof deck including B Decking, metal purlins, metal door frames and guard rails.

Roll Forming Basics

Roll forming machines can process both steel and aluminum sheet metal. The roll forming process is a multi-step process.

Step One

The sheet metal usually begins in a continuous coil. It is placed on a machine called an uncoiler or decoiler. The sheet metal then enters the roll forming machine.

Step Two

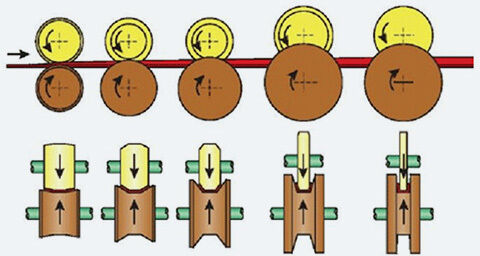

The sheet metal passes through a series of rollers.

Step Three

The rollers not only shape the metal, they also push the metal through the machine. Most roll forming machines process sheet metal at a speed of 30 to 600 feet per minute.

Step Four

Each roller bends the sheet metal a bit more than the previous one.

Step Five

The metal passes through the cut-off press, where it is cut to a pre-programmed length. The newly formed metal unit exits the roll forming machine onto a conveyor belt.

Roll Forming Machine Design

One roll forming machines can produce multiple different variations, or cross-section profiles, of the same product by interchanging the roll sets. Computers are now used to design the roll sets for each specific roll forming job. Roll sets can be expensive to produce, so using a computer design program allows the manufacturer to simulate what the finished product will look like rather than creating multiple test rollers.

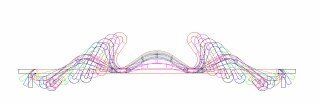

The roll sets are designed with what is called a flower pattern. That is because multiple rollers are needed for each job, starting with the roller creating the least bend in the metal and gradually progressing to the roller creating the greatest bend, which will be the final shape of the metal. When a cross section of each roller is layered on top of each other on one computer image, it looks similar to a flower.Some roll forming machines can create different sizes of finished product using the same roll set by adjusting the space between the rollers manually or via the machine’s computerized system.

Advantages Of Rolling Process

The cold rolling process or cold working process has a great advantage because the metal is not heated for the reshaping process. This gives the finished product more strength and durability. It also allows for the production of lighter weight metal products than a similar process called extrusion. Another advantage of the rolling process is that it requires less energy than the extrusion process. Lastly, roll forming allows for large quantities of sheet metal to be processed into a consistent finished product in a short amount of time.

Roll Forming Machine For Sale

Roll Forming Machines LLC is the leading supplier among Roll Forming Companies world-wide since 2009. Each standard or custom Roll Forming Machine for sale comes with a 1 year warranty for parts and labor plus tech support from our headquarters in Orlando, FL. Please call us today at (407) 859-1119 or e-mail us for a free consultation and quote with the leader among Roll Forming Machine Manufacturers.

Roll Forming Machines LLC's New Factory

Posted on Sunday, March 23, 2025

We have relocated factories, which will be available for tours very soon.

Uncoiler, Decoiler and Coil Car Roll Forming Machine Accesories from Roll Forming Machines LLC

Posted on Sunday, November 24, 2024

Contact us today with your specifications for a custom Uncoiler, Decoiler or Coil Car at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Stud and Track Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Stud and Track Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119

Cee and Zee Purlin Roll Forming Machines from Roll Forming Machines LLC

Posted on Saturday, November 23, 2024

Contact us today with your specifications for a custom Cee and Zee Purlin Machine at sales@rollformerusa.com or call us at (+1) (407) 859 1119