Metal Stud Profile Machines

The Benefits of Metal Stud Profile Machines

Posted on Saturday, June 27, 2020

A Metal Stud Profile Machine has become an increasingly popular choice for manufacturers in the building industry who are looking to produce precision punching and cutting with a roll former that can easily be adjusted to different dimensions as required.

Metal Stud and Track are an excellent choice product to ensure fireproof partitioning, helping builders and project managers to erect these structures with minimal hassle and fuss. Metal Stud profile machines are ideal for the creation of drywall partitions, as well as ceiling suspension for both commercial and residential applications.

The Benefits Of Metal Studs

Many building professionals opt for metal studs because of their robustness and longevity, making them ideal building materials.

Metal studs are beneficial because they:

Resist moisture and humidity so will not rot or warp and remain sturdy and straight for impressive periods Are environmentally-friendly if crafted from steel as they can be recycled and will not emit volatile organic compounds (VOCs) Can stand up to severe weather conditions such as strong winds Remain resistant to termites thus eliminating the need for pest control measures to be implemented Are lightweight making them easy to store and transport Metal studs are often chosen over their wooden counterparts because they will not become rotten or moldy, cannot suffer from termite damage, and are better at withstanding severe weather conditions. Because they do not emit VOCs, they are also the healthier choice.

What Is Dry Lining?

Dry lining is a way of creating wall and ceiling partitions or linings by creating board and metal framing systems. If lining walls, it is crucial to allow for door and window openings. Precise measurements are, therefore imperative, and dry lining ensures this accuracy is achieved.

Many operators in the building industry opt for dry lining over plastering as it is a quicker and simpler process allowing for straightforward installation and lighter overall construction. Choosing dry lining also means that if any changes are necessary, they are more easily actioned, allowing for more flexibility. Dry-lining is also an excellent option to reduce condensation and boost thermal insulation.

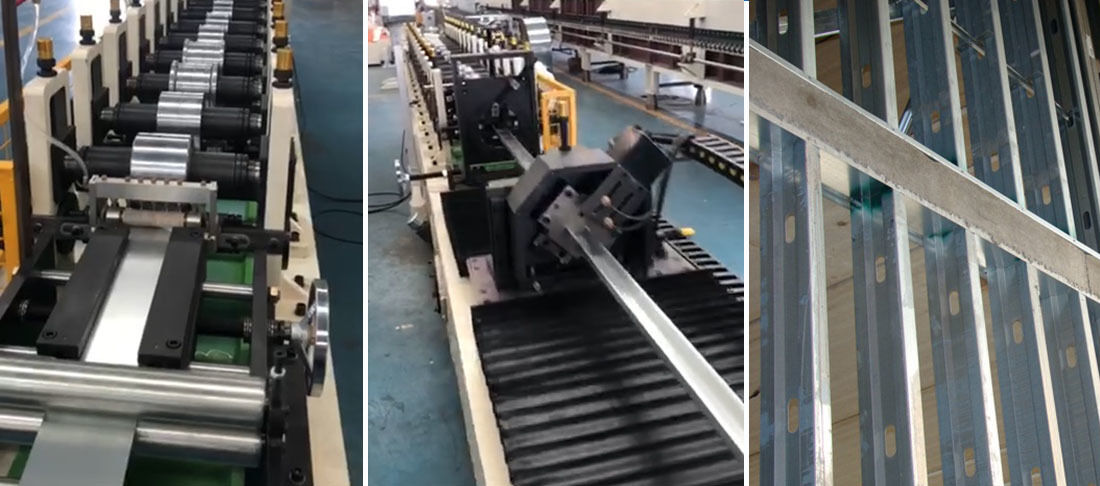

Drywall Stud Track Roll Forming Machine Structure

This type of roll forming machine uses start-stop technology and is made up of an impressive 3 tons of manual uncoiler. It boasts a chain-driven transmission, as well as forming rollers, the mainframe – which includes the guiding platform, cutting, hydraulic system, and stacker.

The entire process of production is controlled by a programmable logic controller (PLC). The rollers can be adjusted manually when creating different product dimensions. The system works by first loading the coil and then feeding the metal sheet to the first forming station where the rolling and forming process occurs. The metal is next fed to the shear where it is cut to the precise measurements required and then passed to the stacker, which will protect the product from damage or scratches, sliding along the rollers and guides before running out.

A Metal Stud Profile Machine is designed to produce precision-cut, durable and excellent quality, non-load-bearing partitions crafted from galvanized steel. These products have several applications, including residential properties, to much larger commercial and industrial uses.

If your business requires a metal stud profile machine, you’ve come to the right place. We offer top-quality, reliable, efficient roll formers that will ensure you end up with a consistent, accurately measured product every time. For more information, browse our collection or get in touch with our professional team today.

ROLL FORMING MACHINE FOR SALE

Roll Forming Machines, LLC is a leader among roll forming companies globally since 2009. We have a fantastic selection of high-quality machines to choose from. All roll forming machines come with a 1 year warranty for parts & labor and technical support from our team in Orlando, FL. Browse our collection here, or get in touch, and one of our customer support team would be delighted to help you.

Posted on Thursday, January 4, 2024

B Deck is a common choice, there are other types of steel roof decks, such as A Deck, F Deck, and N Deck

Robotics and AI in sheet metal forming

Posted on Thursday, December 7, 2023

Robotics and AI in sheet metal forming offers numerous benefits, including increased efficiency, improved product quality

What is the history of roll forming machine?

Posted on Tuesday, November 28, 2023

Here is a brief history of the roll forming machine